A method of supplying injection fluid to a subsea facility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]The invention will now be described in further details with reference to embodiments shown in the drawing in which:

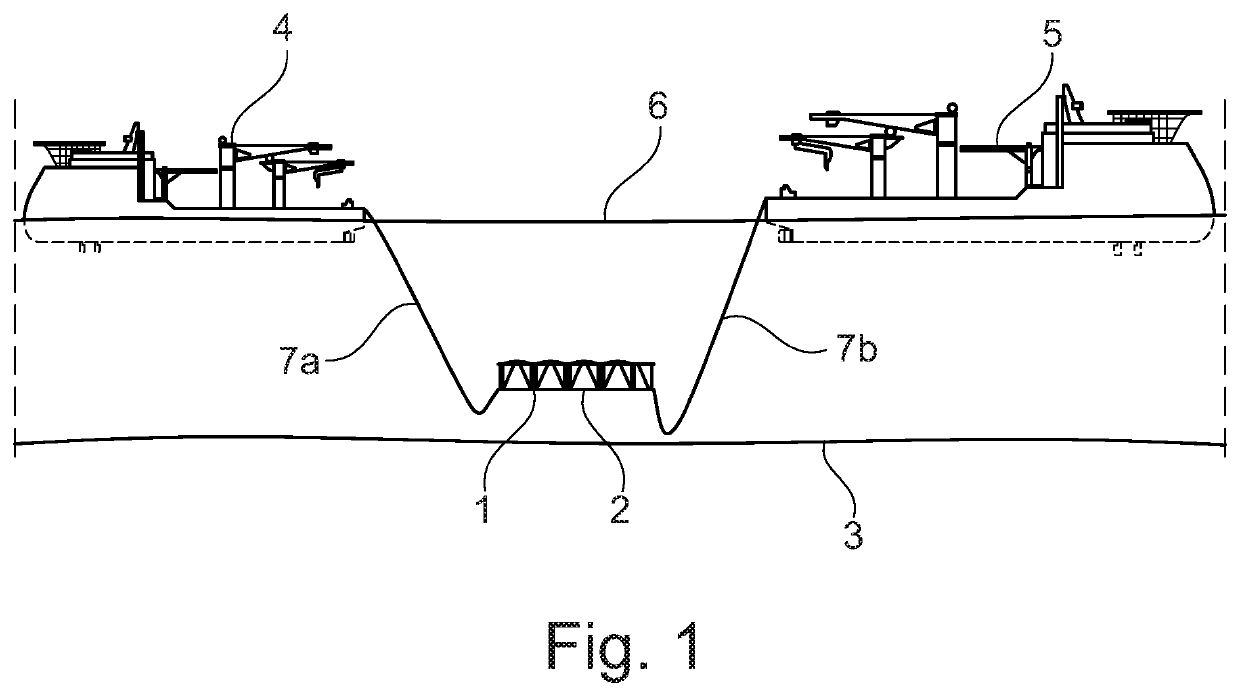

[0051]FIG. 1 shows installation of a rack with storage containers;

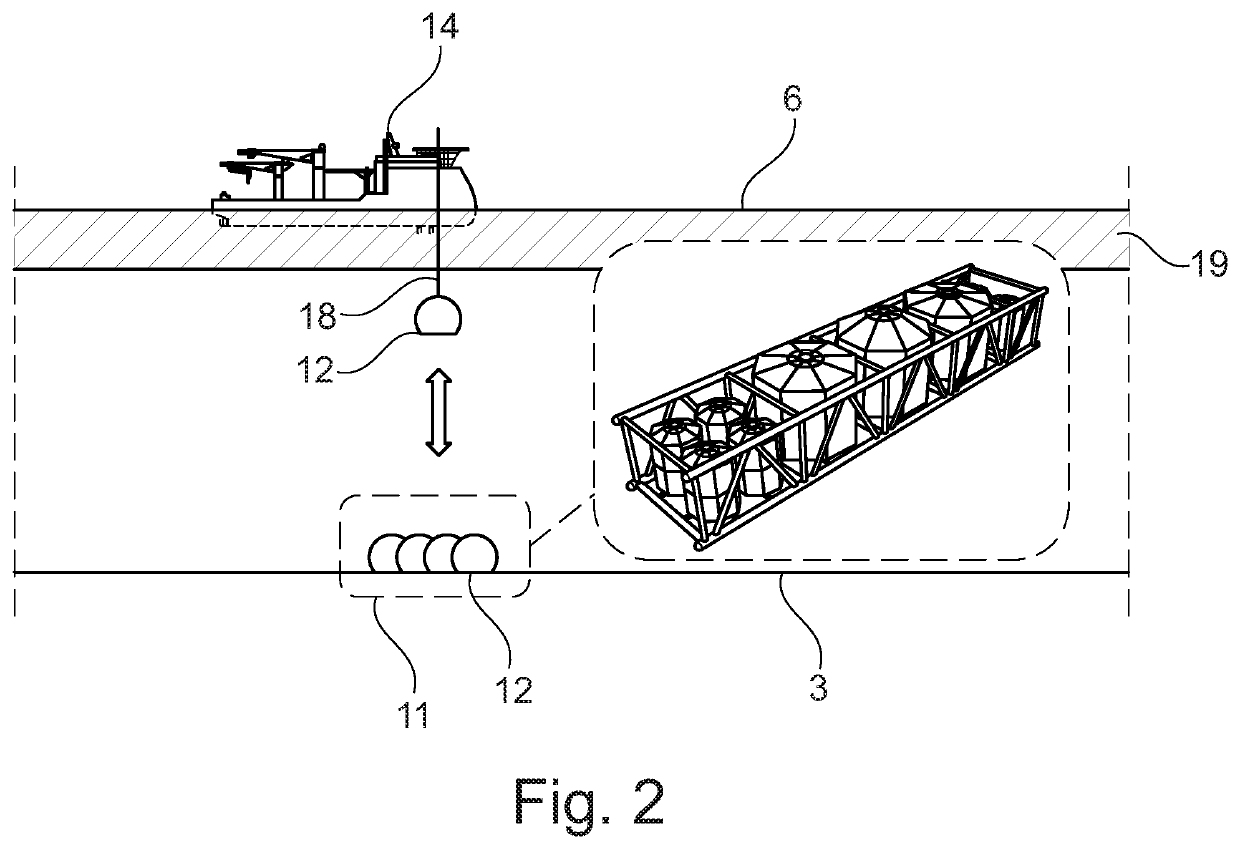

[0052]FIG. 2 shows filling of a storage container according to the invention;

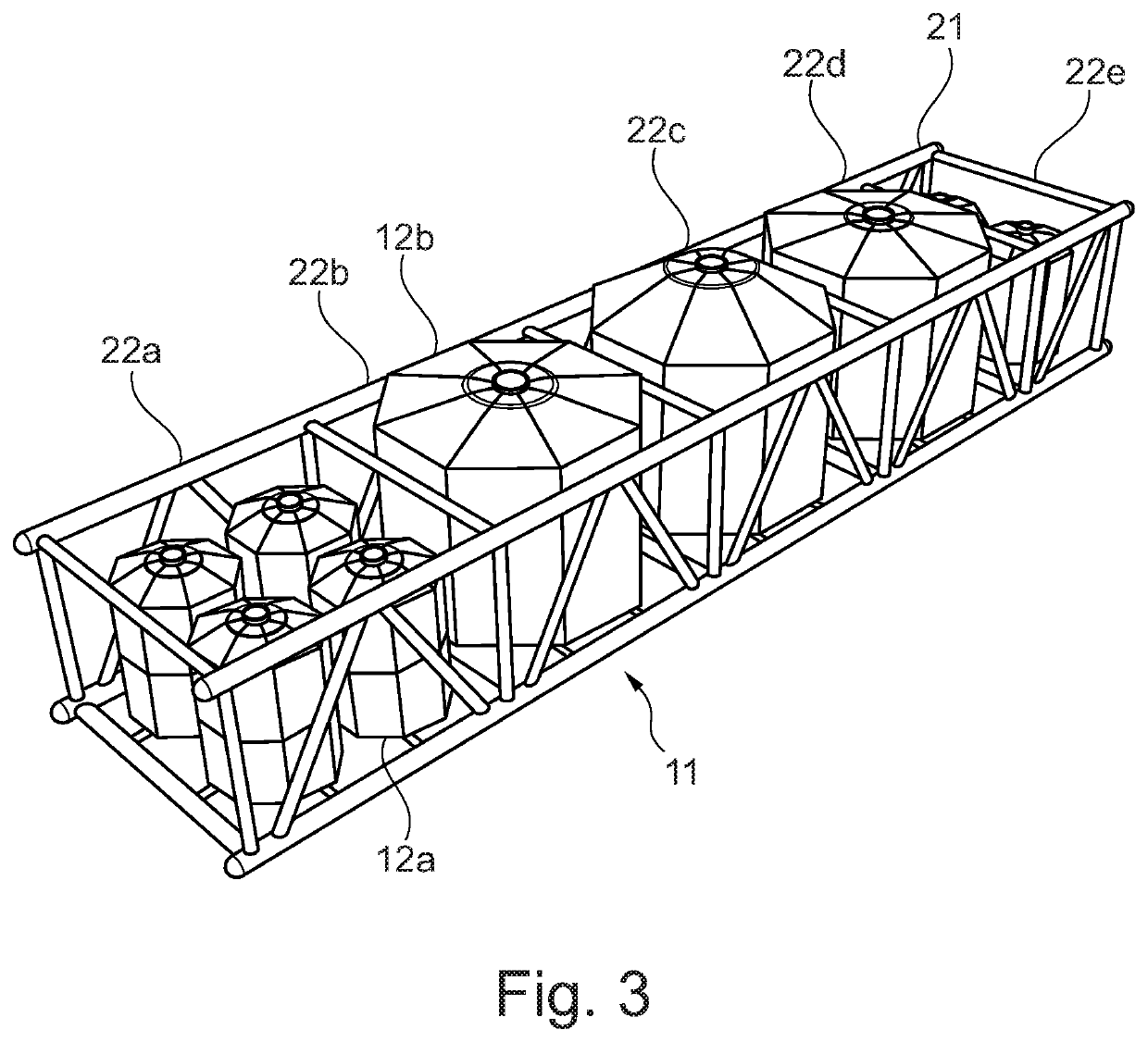

[0053]FIG. 3 shows a foundation and rack structure;

[0054]FIG. 4 shows a storage container with buoyant fluid; and

[0055]FIG. 5 shows a storage container with non-buoyant fluid.

[0056]The figures are not accurate in every detail but only sketches intended to the show the principles of the invention. Details which are not a part of the invention may have been omitted. In the figures the same reference numbers may be used for the same parts.

[0057]FIG. 1 shows the installation of a rack 1 containing a number of storage containers 2. The rack 1 is installed on the seabed 3 near a (not shown) subsea facility.

[0058]The installation of the rack 1 comprises two vessels 4, 5 floating on the sea surface 6. Each vessel is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com