Automotive crash pad and manufacturing method thereof

a technology for autos and crash pads, applied in the direction of vehicular safety arrangements, pedestrian/occupant safety arrangements, synthetic resin layered products, etc., can solve the problems of reduced productivity and economic efficiency, increased process costs, and easy deformation or surface damage of natural leather, and achieve excellent airbag deployment performance and eliminate the process of skin layer weakening

Pending Publication Date: 2022-01-27

HYUNDAI MOBIS CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

The present invention provides an automotive crash pad with excellent airbag deployment performance, economic efficiency, sensitivity properties, and adhesion between the skin layer and foam layer. The pad can quickly deploy airbags in the event of an external shock, even without a skin layer-weakening process. The pad has a good tear shape, is easy to manufacture, and has soft tactile sensation.

Problems solved by technology

However, natural leather has problems in that it is expensive and the quality control thereof is difficult, so that deformation or surface damage of the natural leather easily occurs.

However, when the crash pad is manufactured by performing the skin layer-weakening process, problems arise in that material and process costs increase, resulting in decreases in productivity and economic efficiency, and the labor cost and work time associated with the skin layer-weakening process are added.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

examples 2 to 4

[0309]Crash pads were manufactured in the same manner as in Example 1, except that skin layers having the thicknesses and physical properties shown in Table 1 below were applied.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

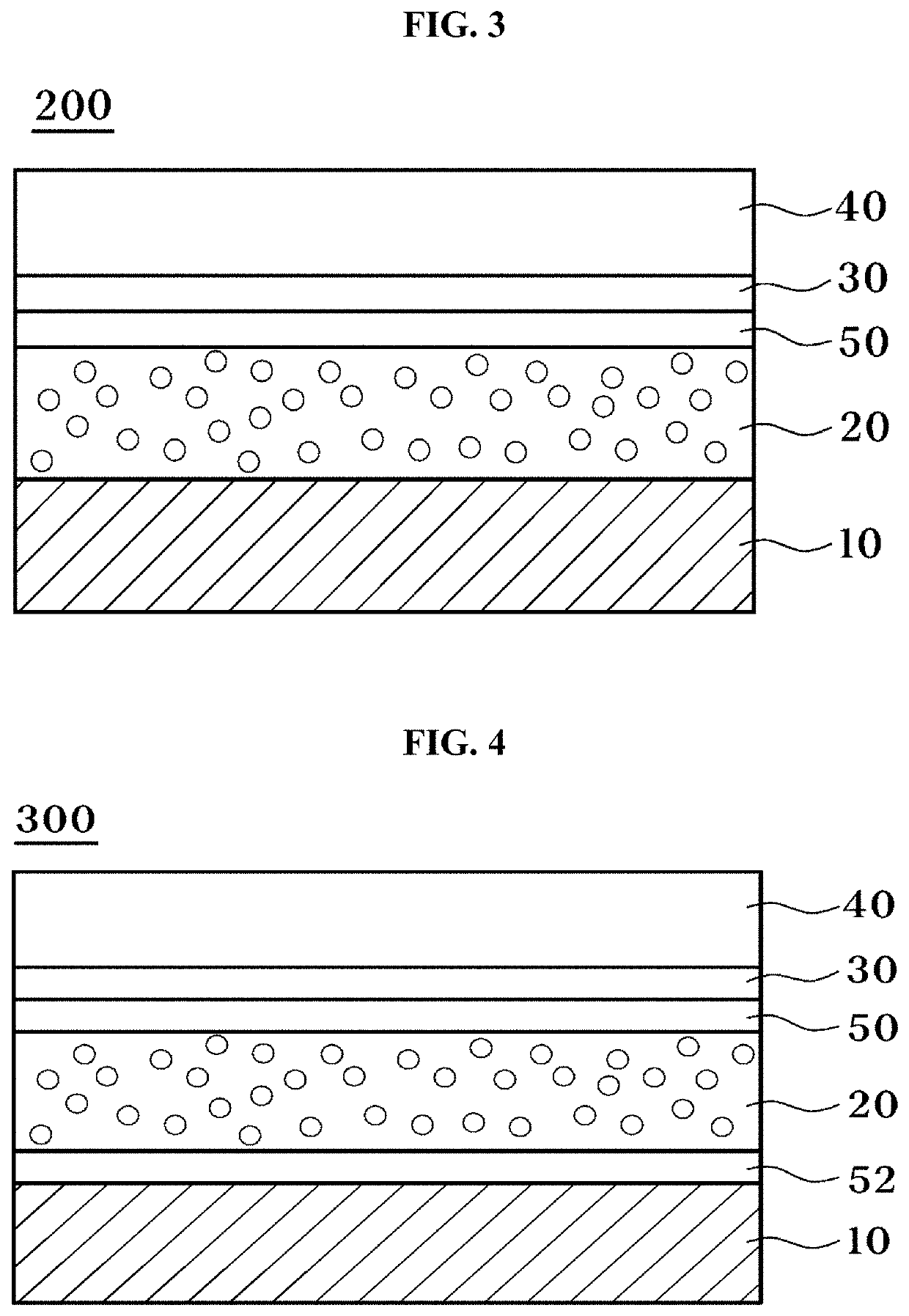

An automotive crash pad and a method for manufacturing the same. The automotive crash pad includes: a skin layer forming the outer surface of the crash pad including an airbag module; a fiber-based layer formed on the lower surface of the skin layer; a cushion layer formed on the lower surface of the fiber-based layer and including slab foam; and a core layer formed on the lower surface of the cushion layer, wherein a laminate of the skin layer and the fiber-based layer has a tensile strength in transverse direction (TD) of 5 to 50 kgf / 3 cm and an elongation at break in transverse direction (TD) of 40 to 220%.

Description

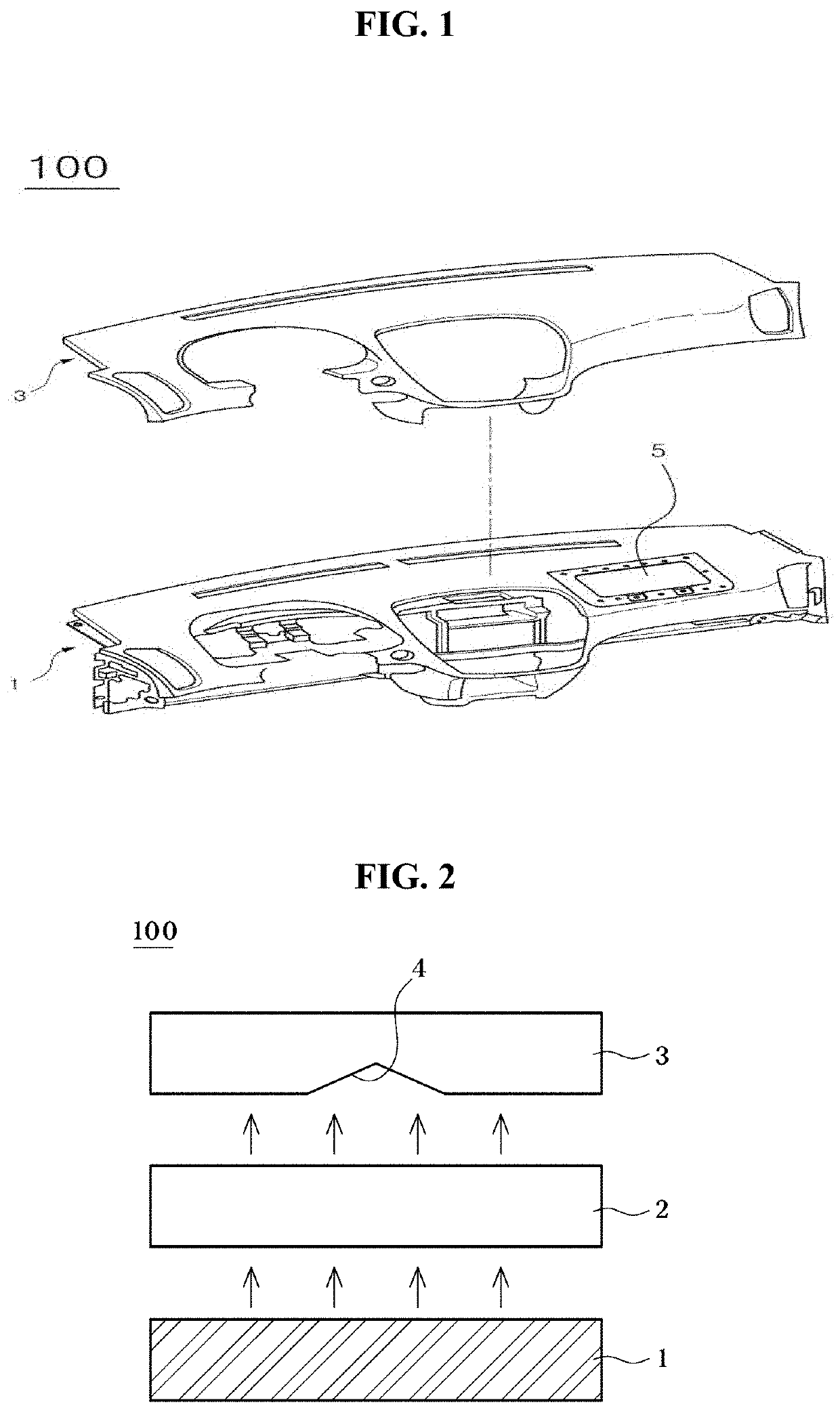

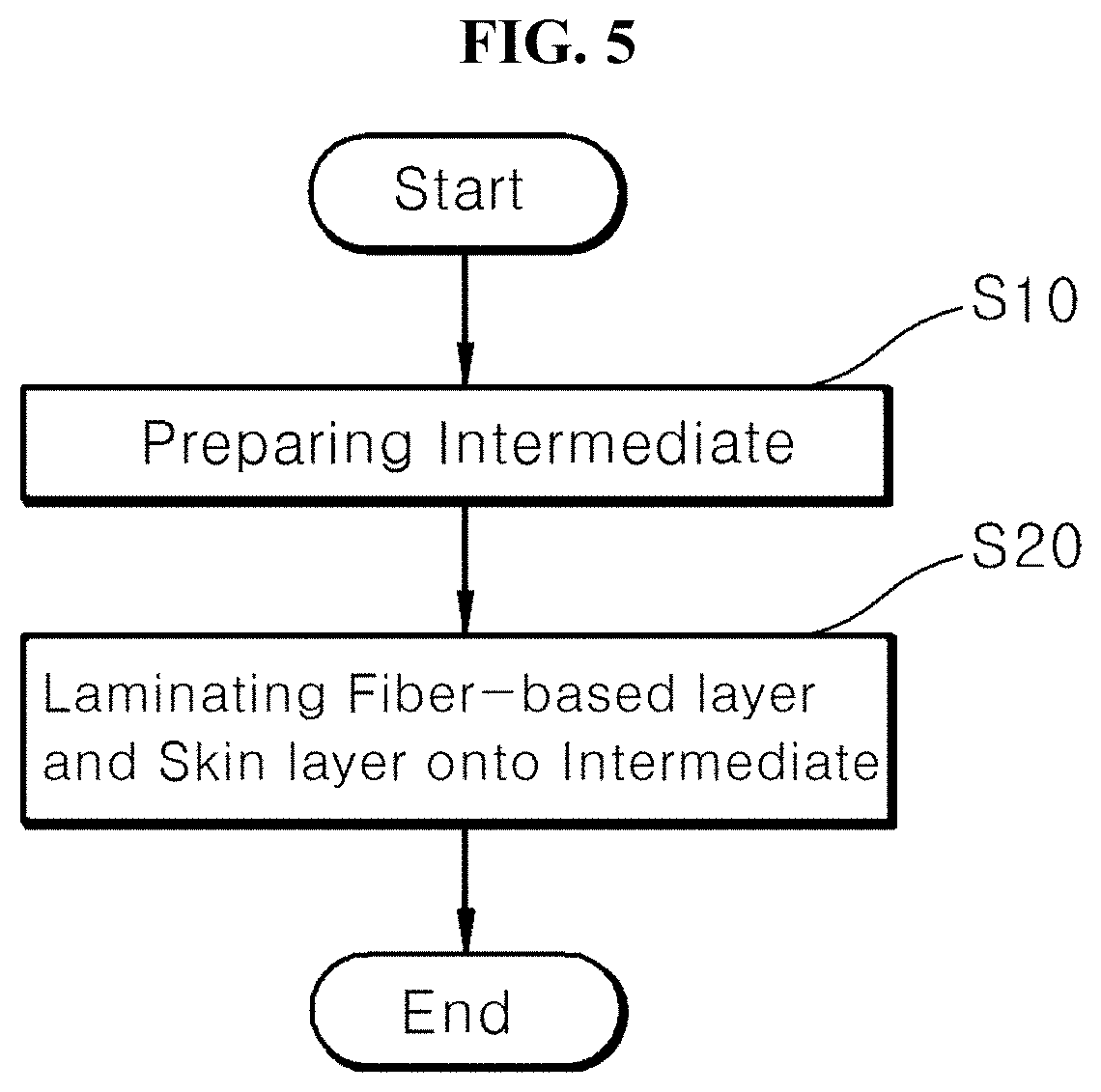

CROSS-REFERENCE TO RELATED APPLICATION[0001]This application claims priority from and the benefit of Korean Patent Application No.10-2020-0090302, filed on Jul. 21, 2020, which is hereby incorporated by reference for all purposes as if set forth herein.BACKGROUNDField[0002]Exemplary embodiments of the present disclosure relate to an automotive crash pad and a manufacturing method thereof.Discussion of the Background[0003]A crash pad, also called an instrument panel, is an automotive interior part that is attached to the lower end of the front glass of the driver's seat. An airbag is mounted in the crash pad. The airbag functions to protect the occupant's life from an external shock by deployment through the seam line of the crash pad when a crash occurs. Thus, the airbag is a very important part in terms of design, convenience and stability.[0004]FIG. 1 illustrates a conventional automotive crash pad, and FIG. 2 illustrates a conventional crash pad. Referring to FIGS. 1 and 2, a cra...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(United States)

IPC IPC(8): B60R21/045B60R21/205B60R21/215B32B5/20B32B7/12B32B5/02B32B5/24B32B27/06B32B27/12B32B27/40

CPCB60R21/045B32B2605/003B60R21/215B32B5/20B32B7/12B32B5/022B32B5/026B32B5/245B32B27/065B32B27/12B32B27/40B32B2307/732B32B2307/54B32B2307/5825B32B2307/72B32B2266/0278B60R21/205B32B5/18B32B27/20B32B27/32B32B27/365B32B27/302B32B33/00B32B37/12B60R13/0256B32B2262/0284B32B2255/26B32B2255/10B32B2307/552B32B2307/306B32B2307/558B60R21/2165B32B27/16B32B2255/102B32B2274/00B32B2307/308B32B2307/714B32B2255/28B32B2250/04B32B2255/02B32B27/304B60R21/04B32B2605/08B60Y2304/05B32B37/142B32B2037/266B32B2038/0084B32B2305/10B32B2305/022

Inventor KIM, DO HYUNGSON, CHANG WAN

Owner HYUNDAI MOBIS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com