Plate-type heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

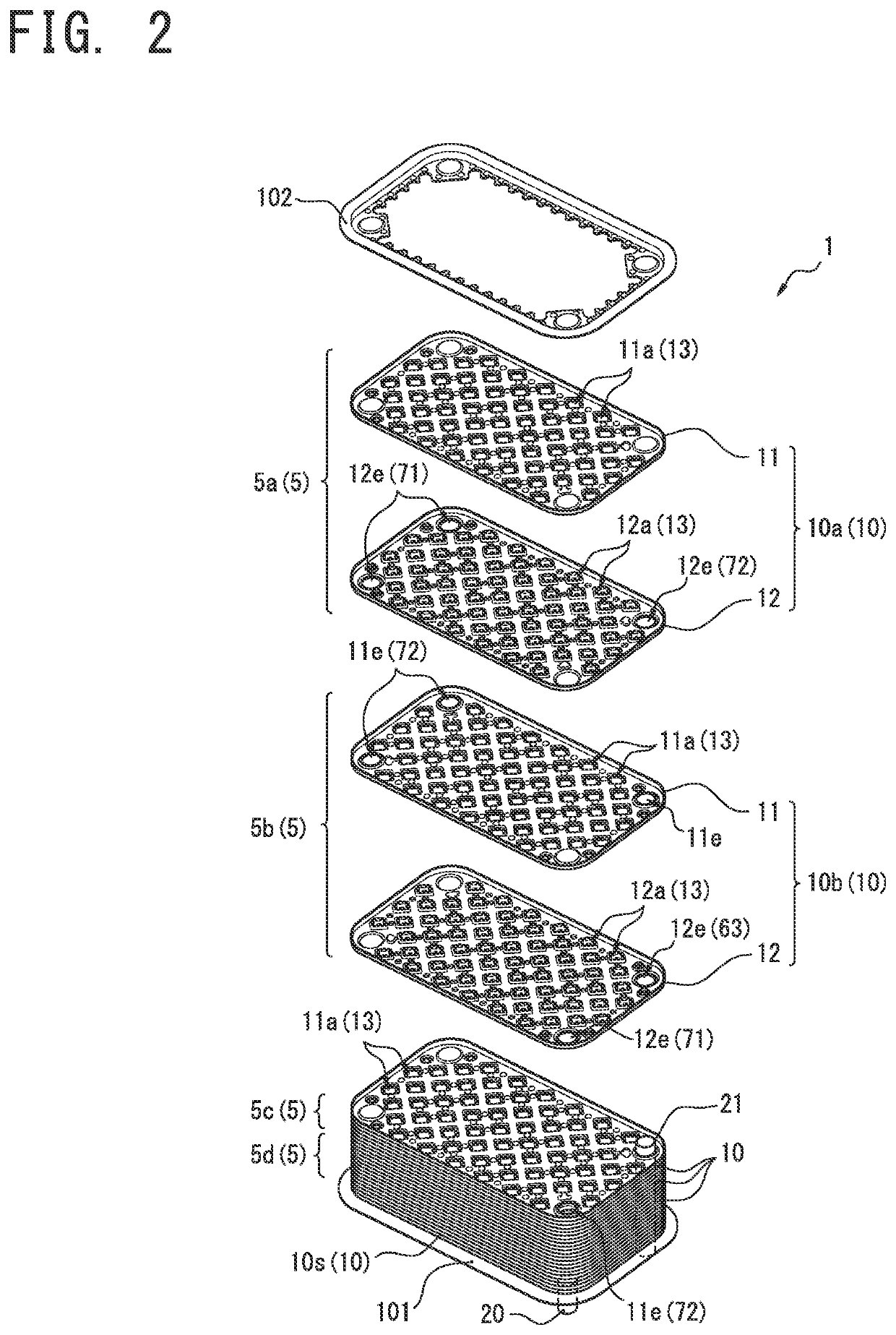

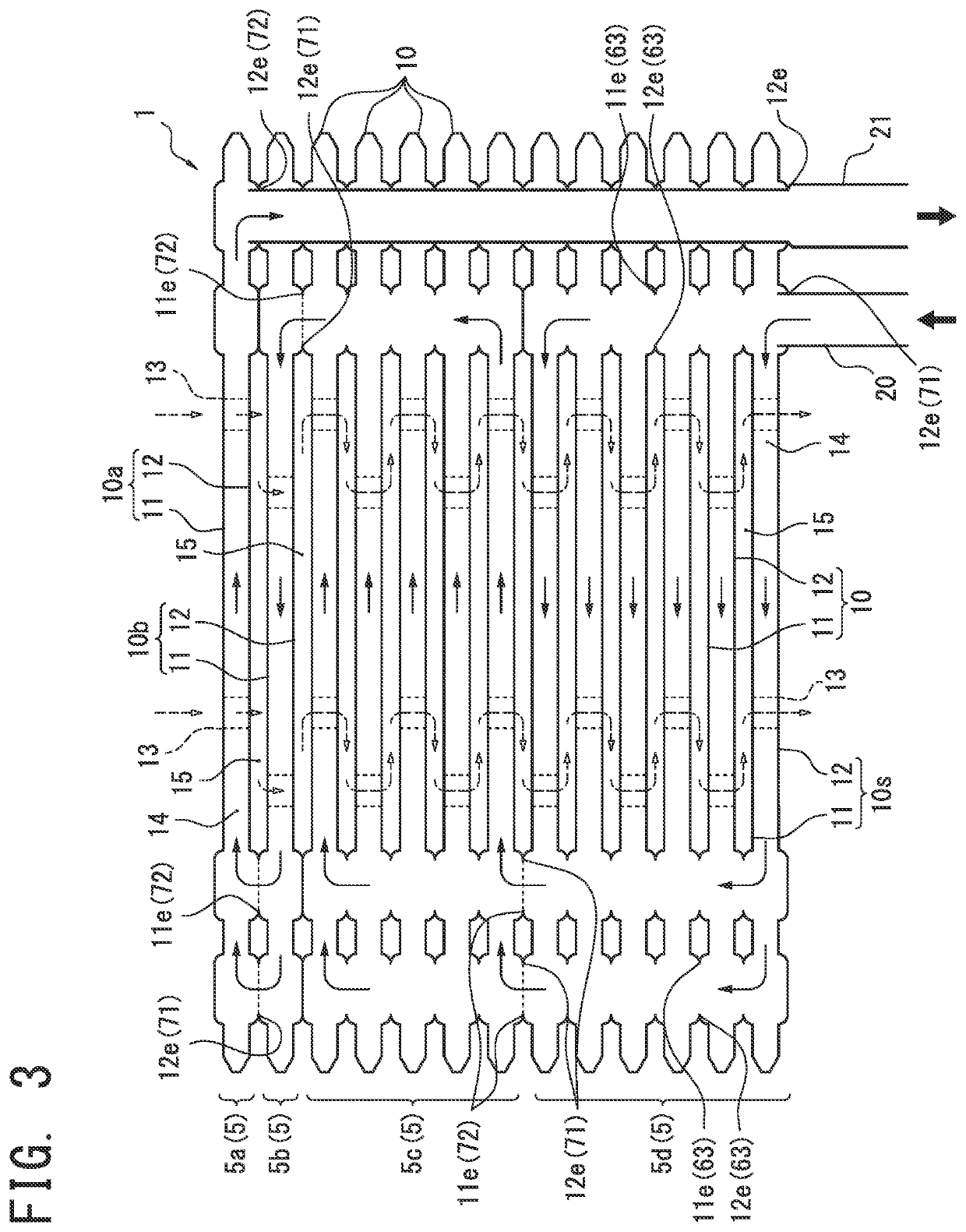

[0022]Hereinafter, referring to drawings, a heat exchanger and a heat source device using thereof according to an embodiment of the present invention will be described in detail.

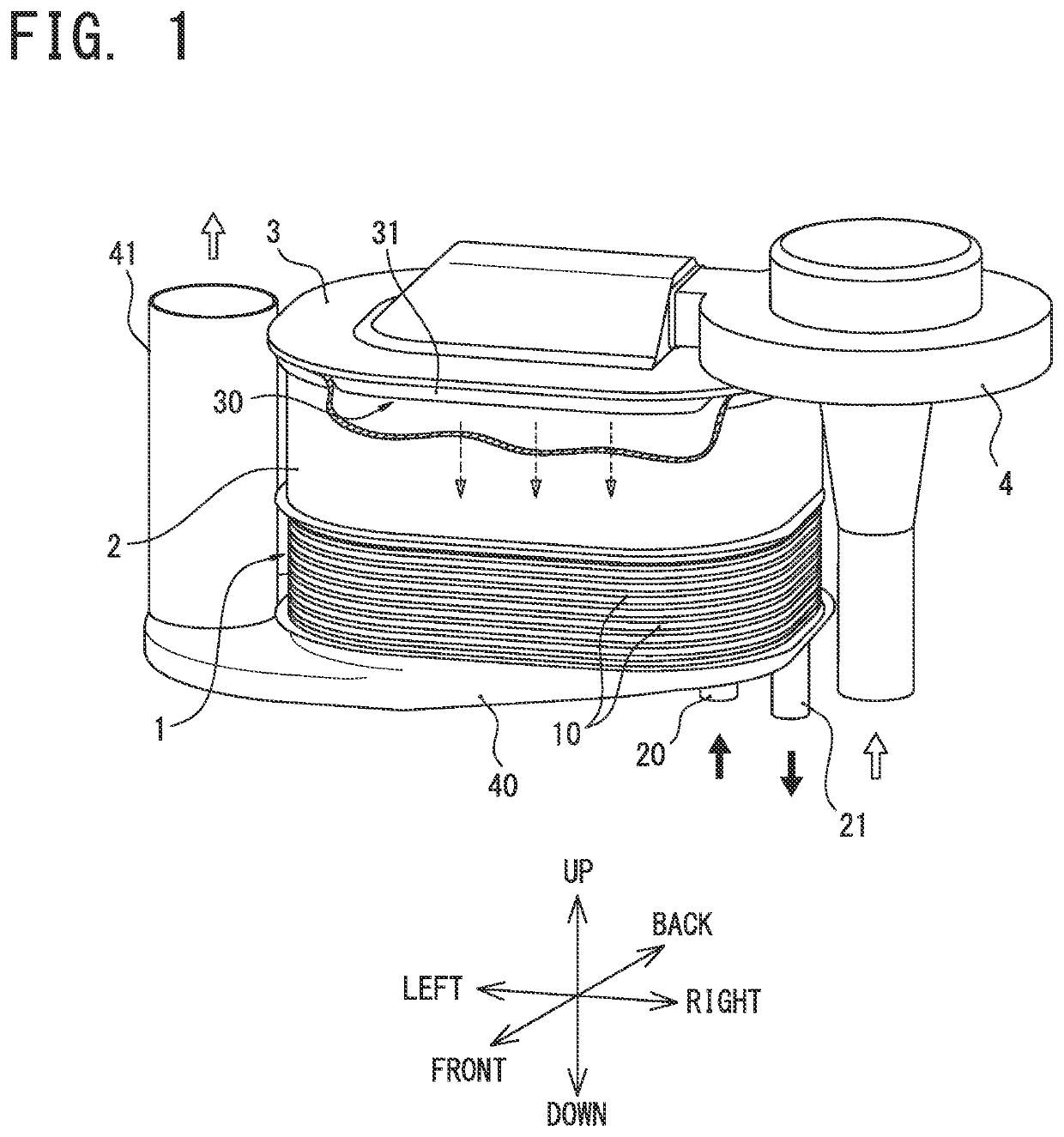

[0023]As illustrated in FIG. 1, a heat source device according to the present embodiment is a water heater that heats water (heat medium) as first fluid flowing into a heat exchanger 1 through an inlet pipe 20, with combustion exhaust gas as second fluid generated in a burner 31 and supplies the heated water to a hot water supplying terminal (not illustrated) such as a faucet or a shower head through an outlet pipe 21. Although not shown, the water heater is accommodated in an outer casing. Other heating medium (for example, an antifreezing fluid) as the first fluid may be used.

[0024]The water heater includes a burner body 3 constituting an outer shell of the burner 31, a combustion chamber 2, the heat exchanger 1, and a drain receiver 40 that are disposed in this order from above. Additionally, the fan casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com