Contact-less probe of semiconductor wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

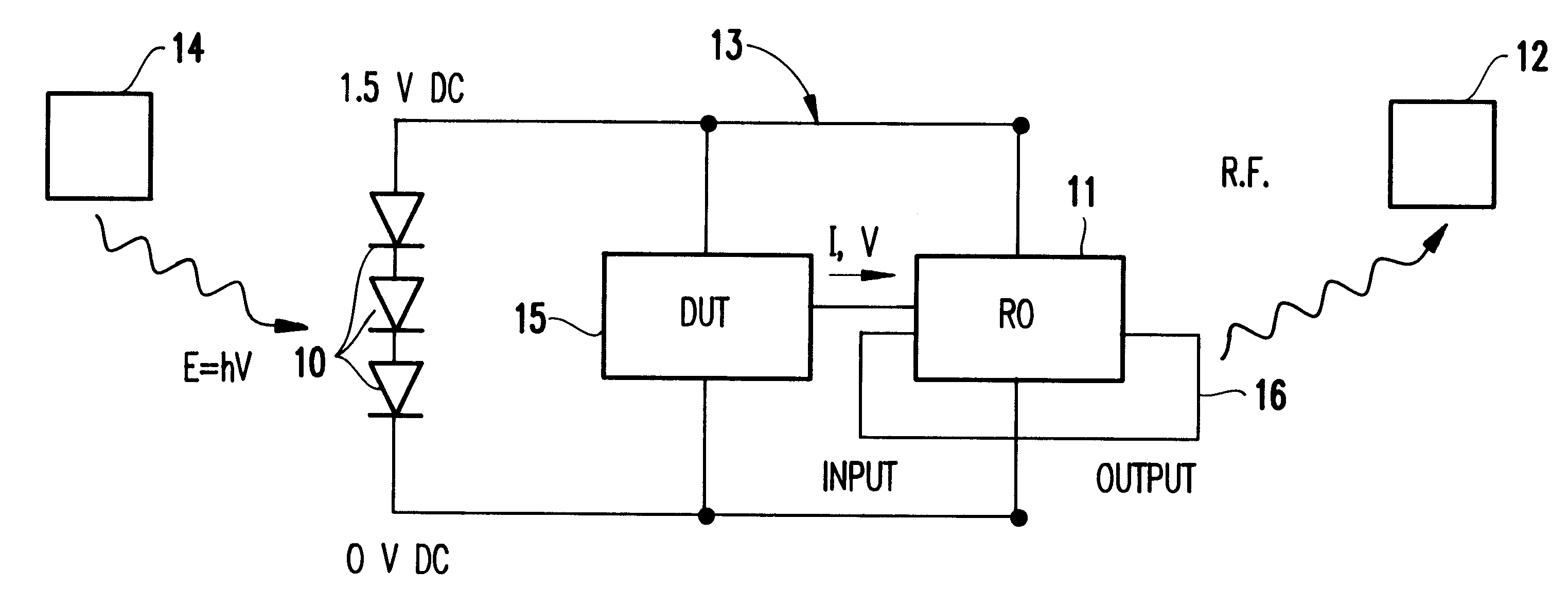

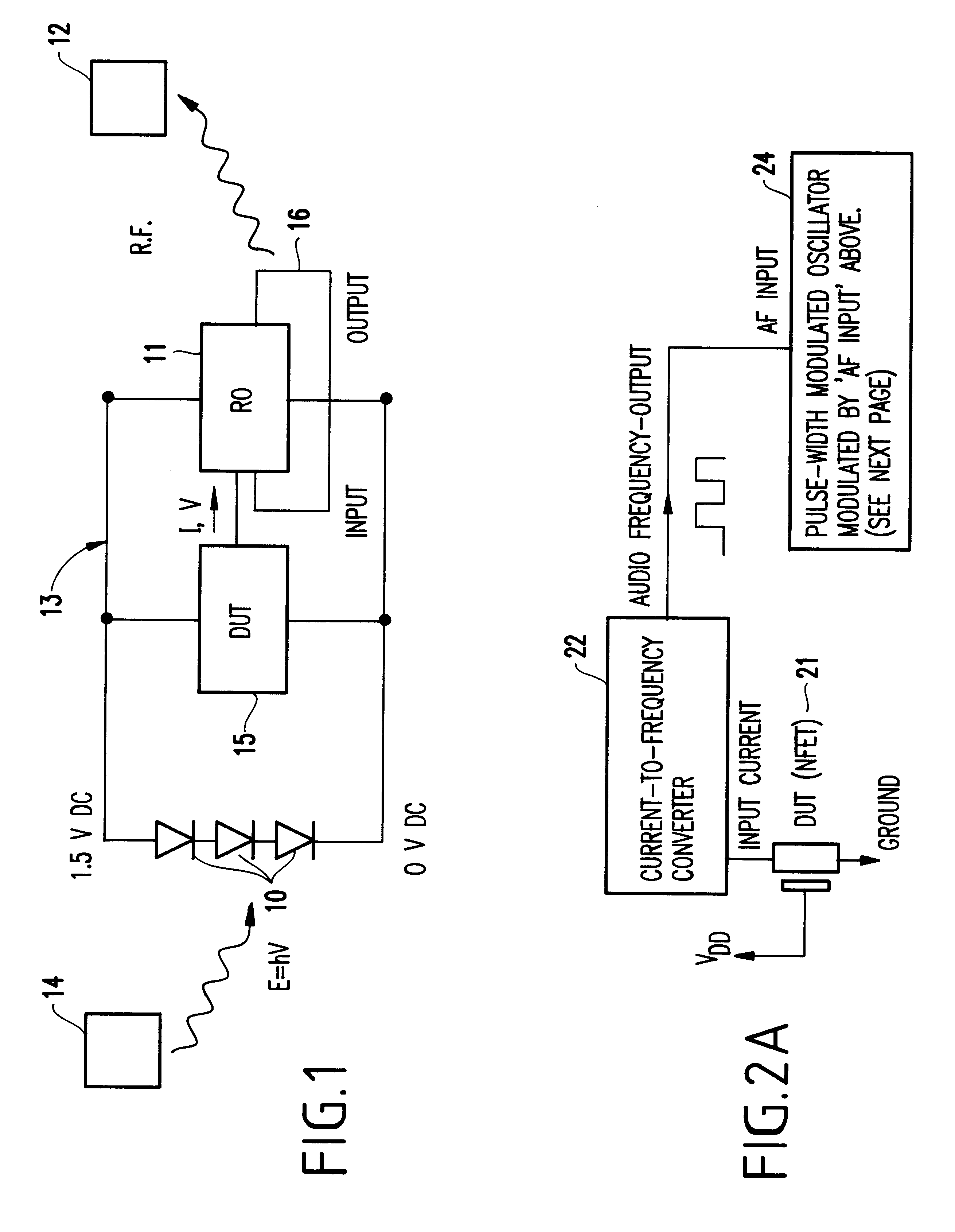

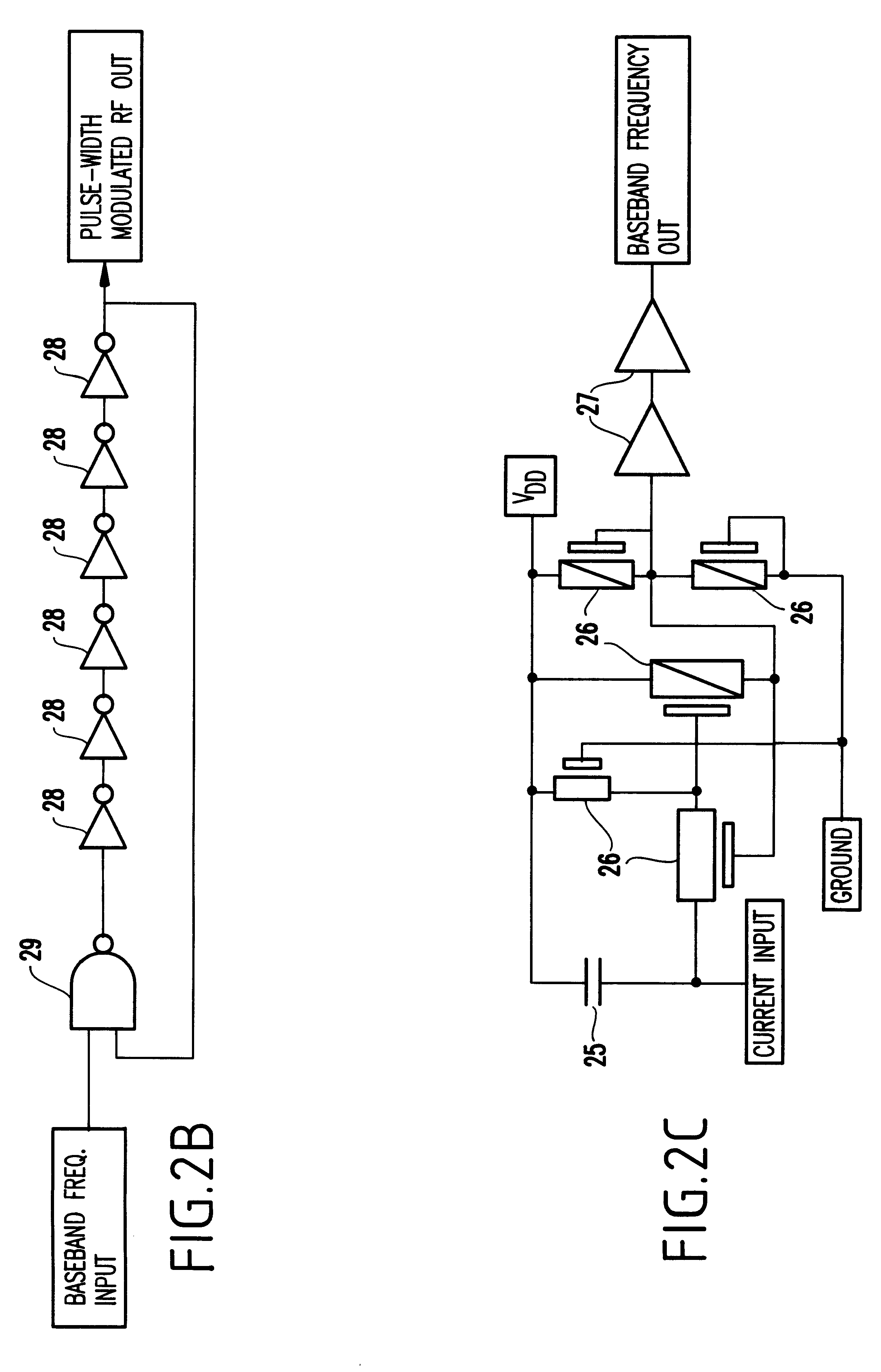

Referring now to the drawings, and more particularly to FIG. 1, a a contact-less probe is illustrated. As mentioned above, the present invention provides a structure and method for determining important device parameters and in-line yield parameters (such as device channel length and metal defects), without physically probing (contacting) the item being manufactured.

The invention includes a light powered generator 10, a radio frequency generator 11, a radio frequency receiver 12, a charge transfer circuit 13 and a light source 14 to power the device under test (DUT) 15, as shown in FIG. 1.

When the DUT 15 is powered by the charge transfer circuit 13, the DUT 15 will send a voltage or current to the radio frequency generator 11 (e.g., ring oscillator). Depending on the DUT output, the radio frequency generator 11 output frequency will vary accordingly.

A radio frequency generator is one of the most versatile process and device monitors. For example, a radio frequency generator can be u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com