Leadless image sensor package structure and method for making the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

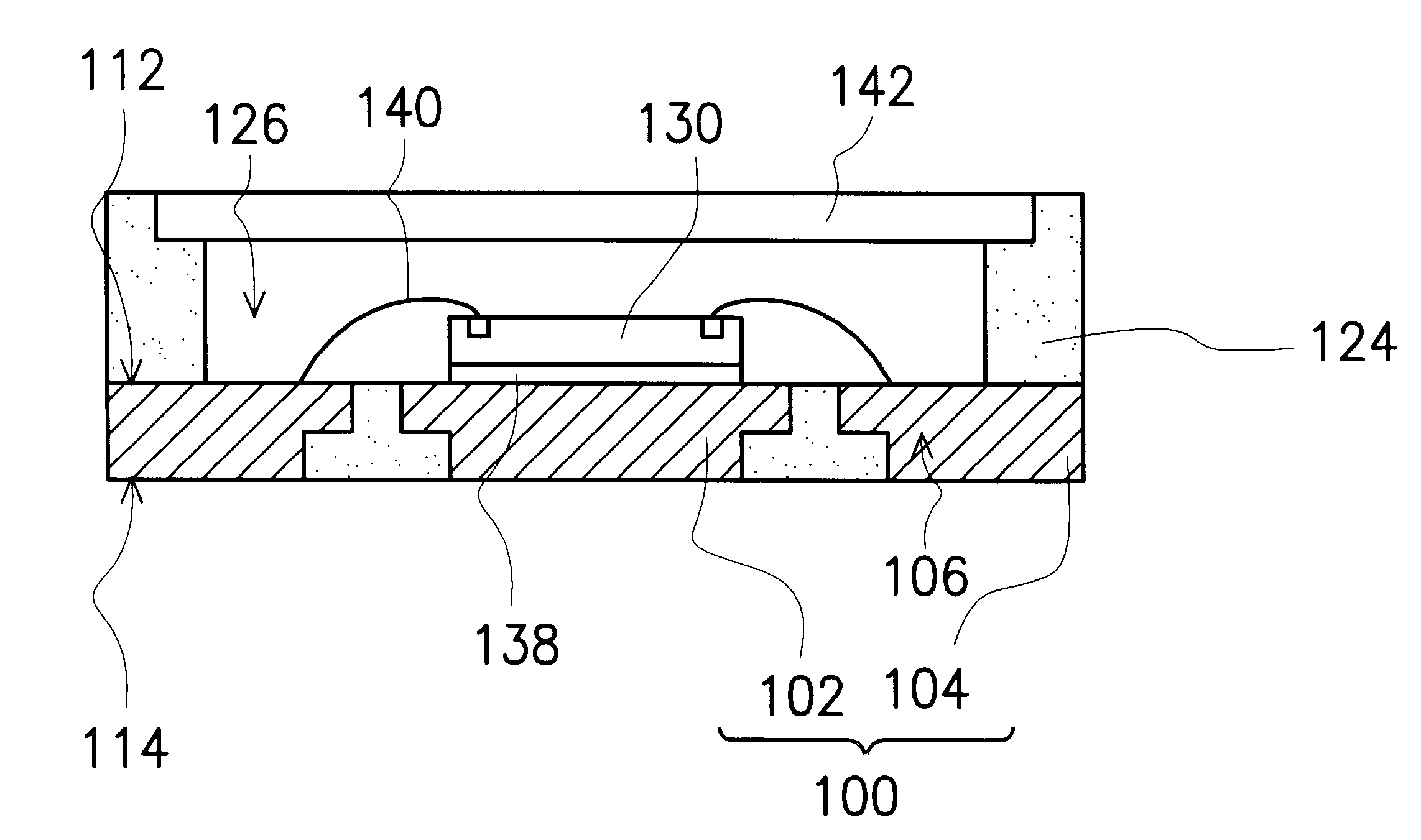

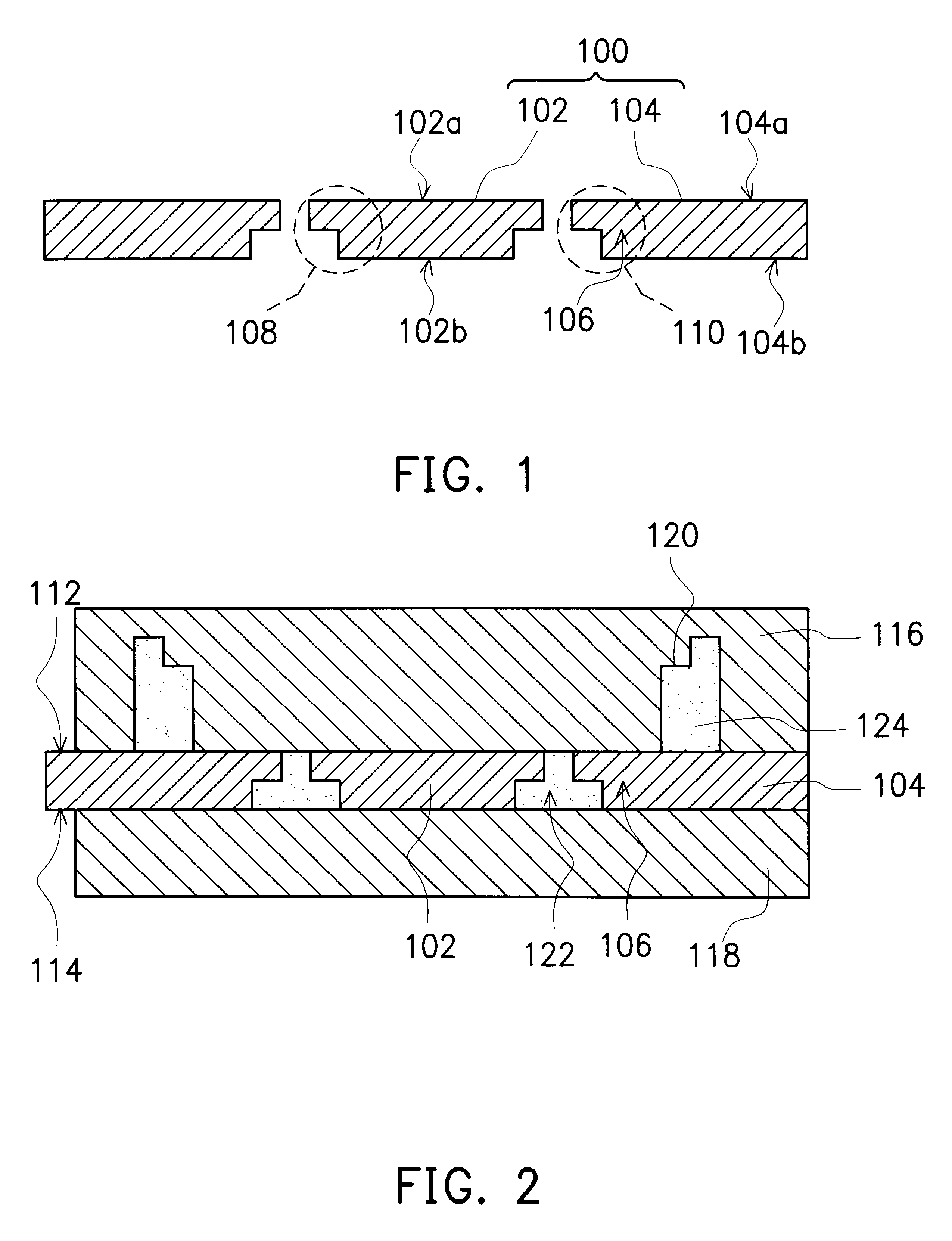

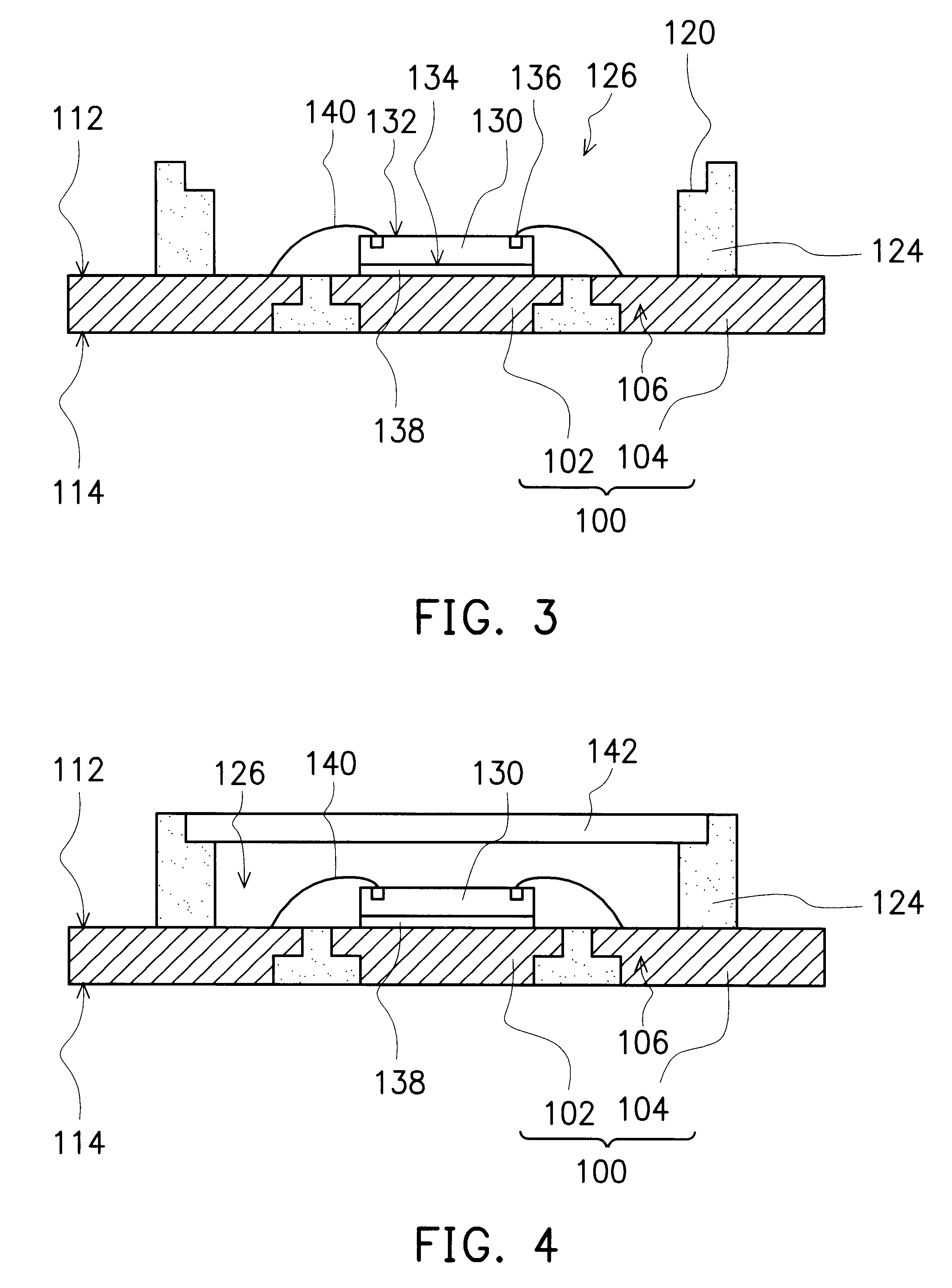

FIG. 1 through FIG. 5 are cross-sectional views of a manufacturing process of a leadless image sensor package structure according to the invention. The leadless image sensor package structure of the invention is constructed on a lead frame 100 that includes a die pad 102 and a plurality of leads 104 disposed at the periphery of the die pad 102 and surrounding thereof. In this embodiment, the die pad 102 has a top surface 102a larger than its bottom surface 102b and a top surface 104a of the lead 104 is also larger than its bottom surface 104b. Therefore, a step-like structure 108 or 110 is formed at the periphery of the die pad 102 and at the wire-bonding portion 106 of the leads 104. The step-like structures 108 and 110 are formed by a "half etching method" or a "coining method" so that the thickness of a portion of the step-like structure 108, 110 can be reduced. The step-like structure s 108 and 110 are used to improve bondability between the lead frame 100 and a below-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com