Tissue and towel products containing crosslinked cellulosic fibers

a technology of crosslinked cellulosic fibers and towel products, which is applied in the directions of non-fibrous pulp addition, transportation and packaging, natural mineral layered products, etc., can solve the problems of reducing sheet strength, reducing hemicellulose content, and reducing hemicellulose content, so as to achieve high hemicellulose content, bulk and absorbent capacity, and high hemicellulose content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

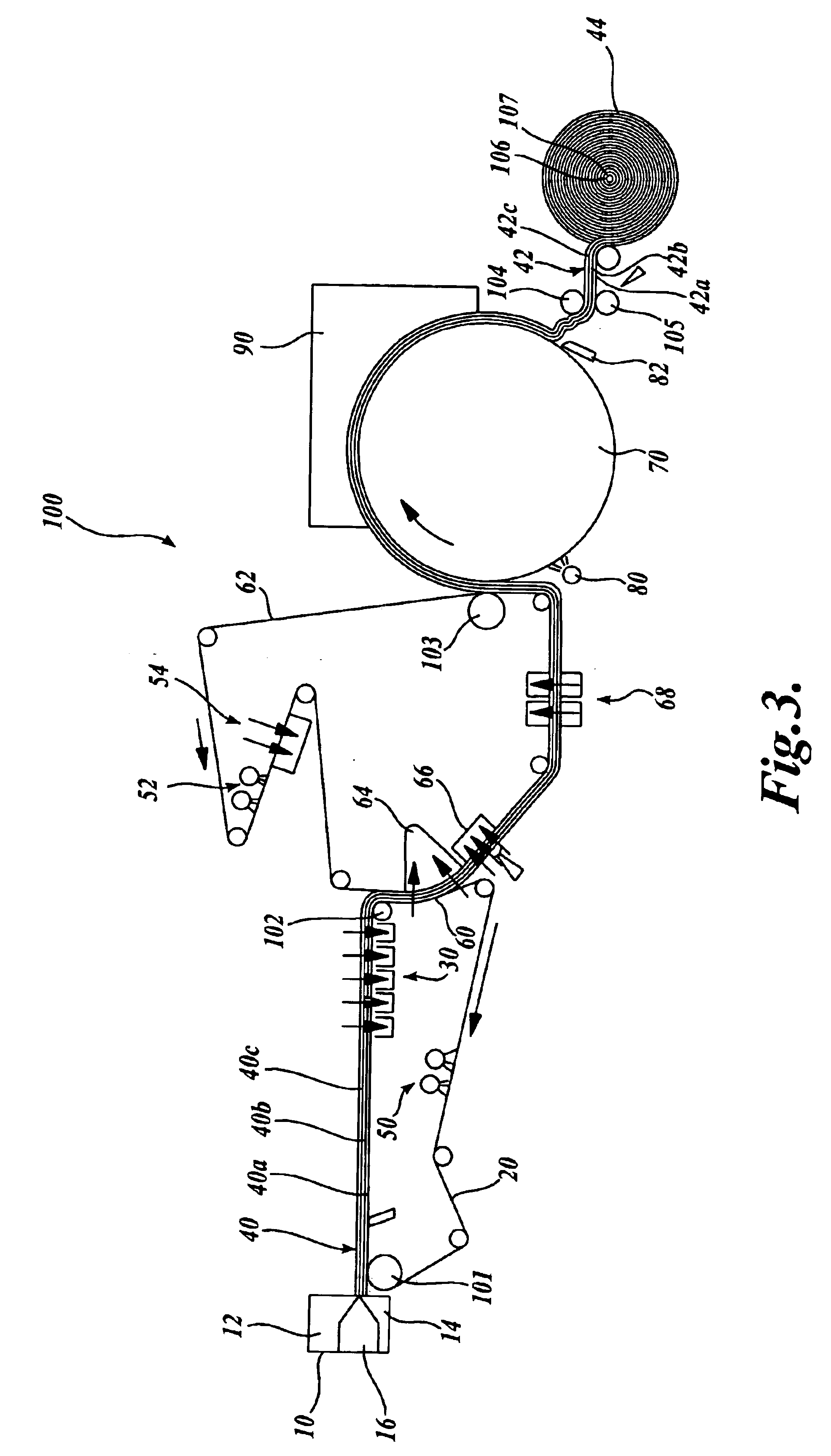

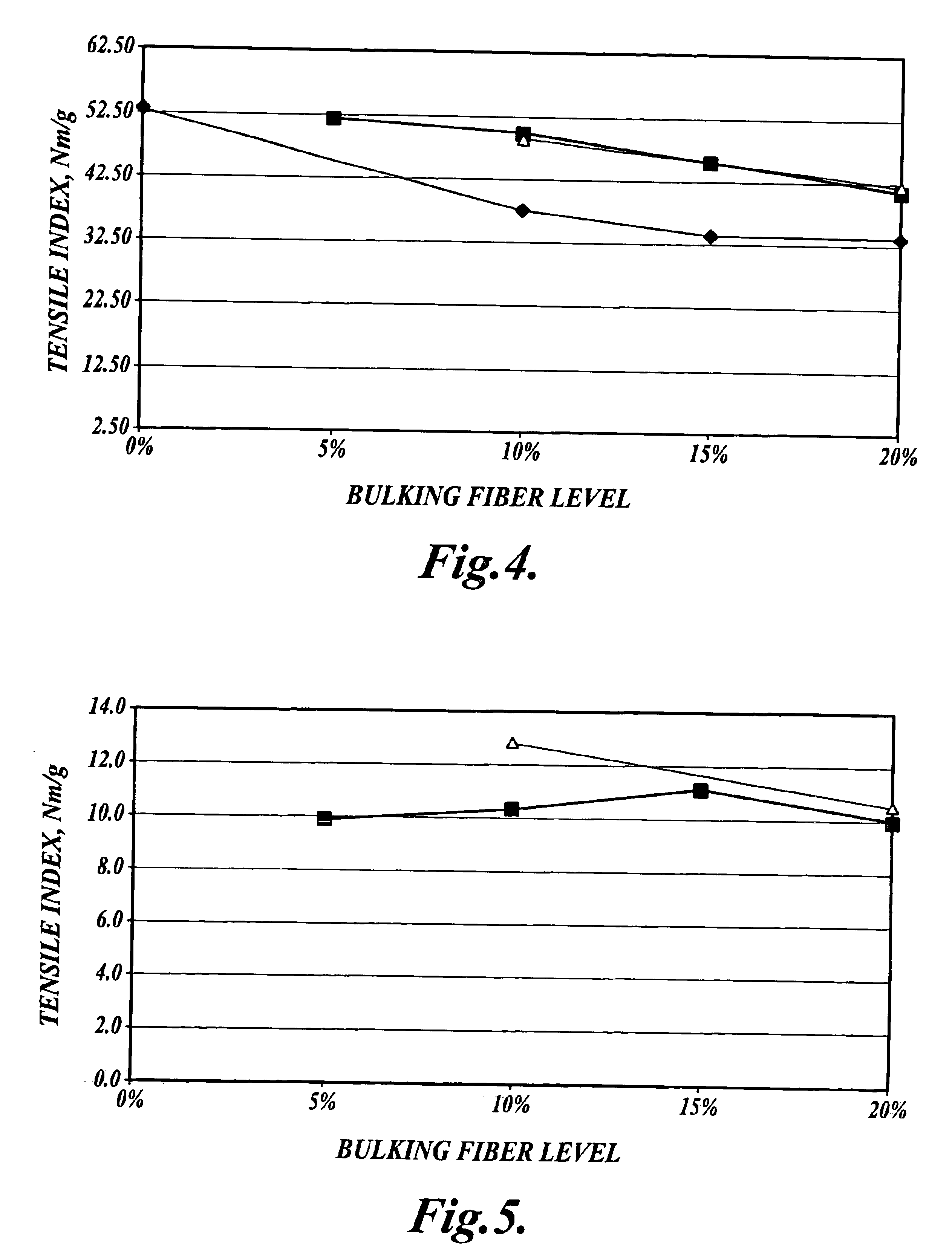

In one aspect, the present invention provides a fibrous product that includes crosslinked cellulosic fibers. In addition to crosslinked cellulosic fibers, the product also includes softwood fibers prepared by the kraft process (i.e., softwood kraft pulp fibers) having a high hemicellulose content compared to other kraft softwood fibers and hardwood fibers. The softwood kraft pulp fibers having a high hemicellulose content and hardwood fibers impart strength to the fibrous product. Without being bound to the theory, it is believed that the advantageous bulk imparted to the fibrous product of the invention by the incorporation of crosslinked cellulosic fibers is accompanied by a diminution of sheet strength, which is returned to the fibrous product by the inclusion of softwood kraft pulp fibers having high hemicellulose content and hardwood fibers.

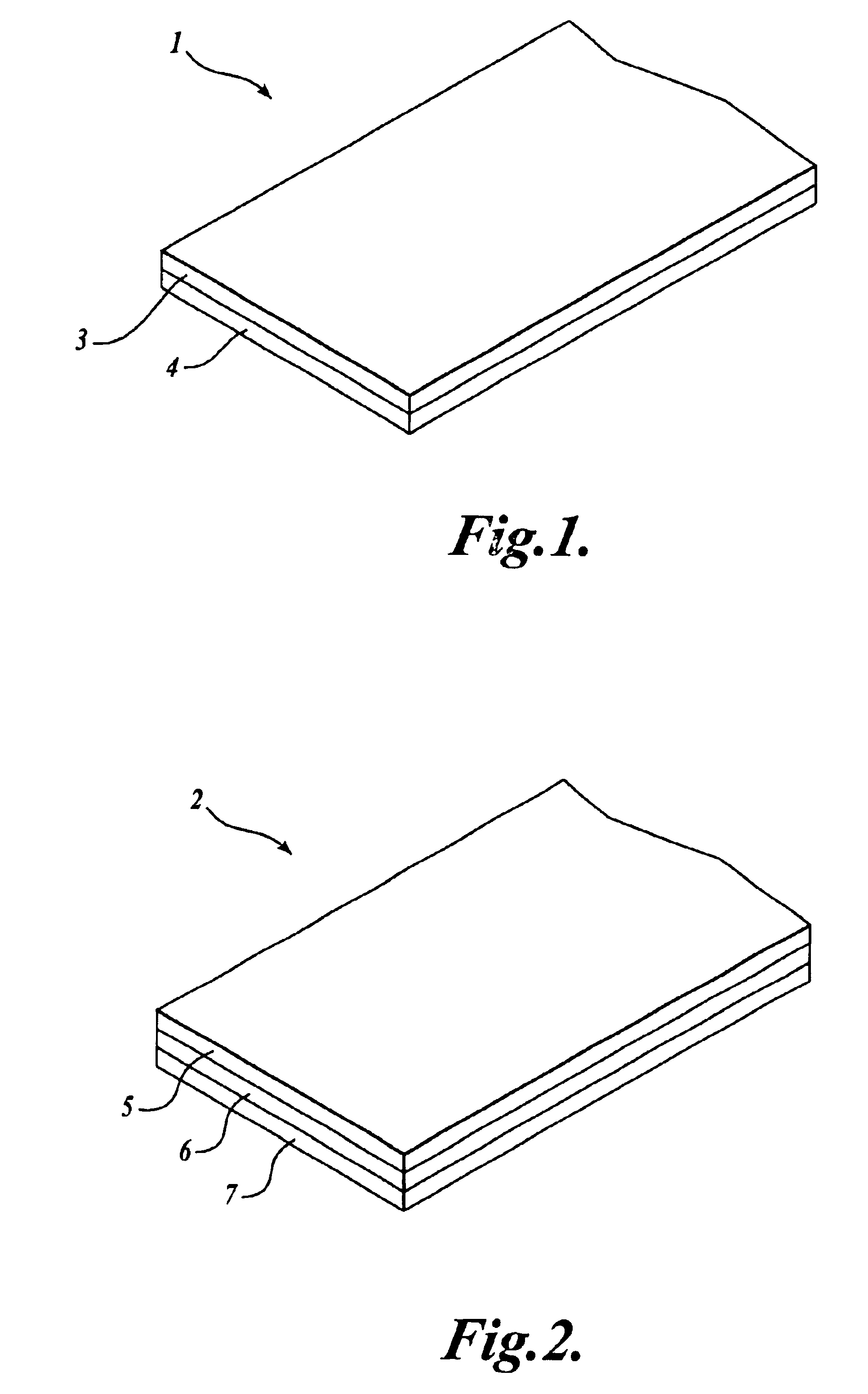

The fibrous product of the invention can be a facial tissue, toilet tissue, disposable wipe, napkin, handkerchief, or paper towel. The fibr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter×about | aaaaa | aaaaa |

| diameter×about | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com