Door mirror set plate

a technology for door mirrors and set plates, applied in the field of car door mirrors, can solve the problems of insufficient strength of the support shaft, inability to resist stress concentration, and inability to meet the needs of the user, and achieve the effect of enhancing strength and functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

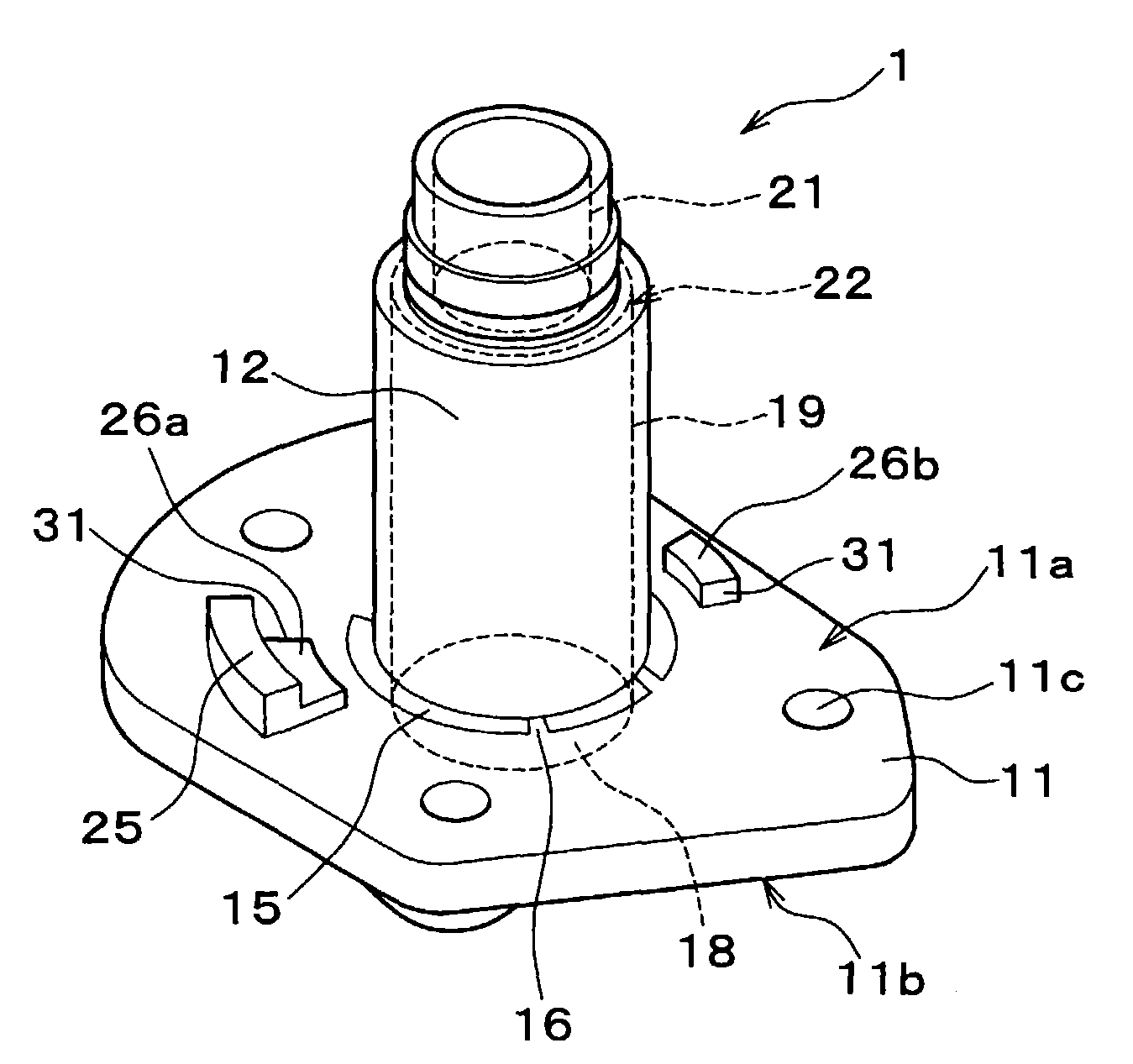

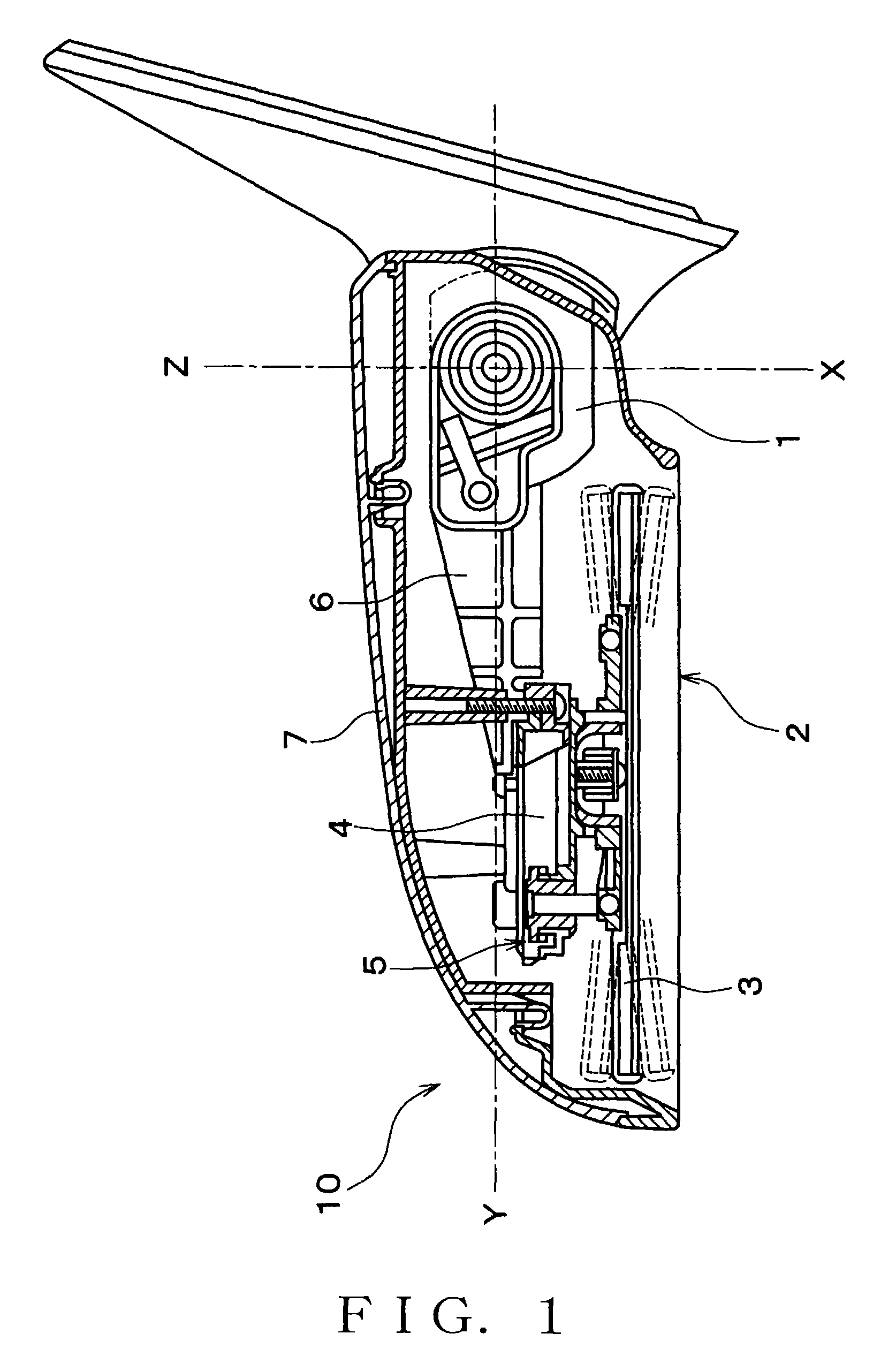

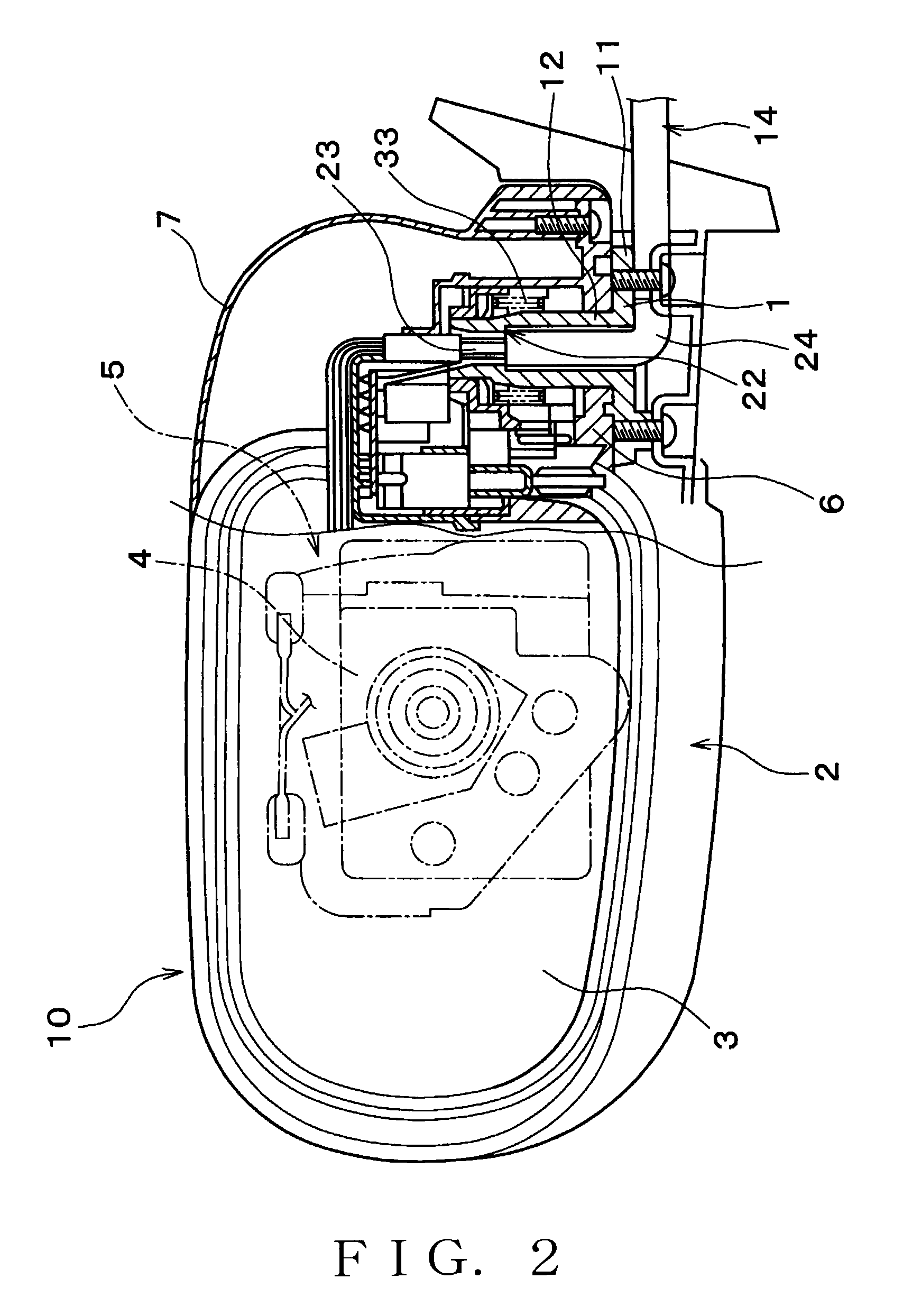

[0031]An embodiment of the present invention will be described in further detail with reference to the accompanying drawings. As shown in FIG. 1, a door mirror 10 comprises a door mirror set plate 1 (hereafter abbreviated to a set plate 1) and a door mirror body 2. The set plate 1 is fixed to a body side of the car. The door mirror body 2 is rotatively attached onto the set plate 1. The door mirror body 2 further comprises a body 5 and a bracket 6. The body 5 contains a drive unit 4 comprising a mirror plate 3, a motor, and the like. The bracket 6 holds the body 5 and is rotatively attached to the set plate 1.

[0032]The door mirror 10 is a so-called electric retractable apparatus. The door mirror body 2 can rotatively move approximately 180 degrees from a retracted position X to a safety position Z via a neutral position Y around the set plate 1 by means of the drive unit 4. The drive unit 4 allows angles of the mirror plate 3 to be controlled remotely. The door mirror body 2 is exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com