Shield tunneling method and shield tunneling machine

a shield tunneling and shield tunneling technology, applied in the direction of shaft equipment, shaft lining, snow cleaning, etc., can solve the problems of restricting ground and inability to effect long-distance tunneling, and achieve the effect of stable tunneling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

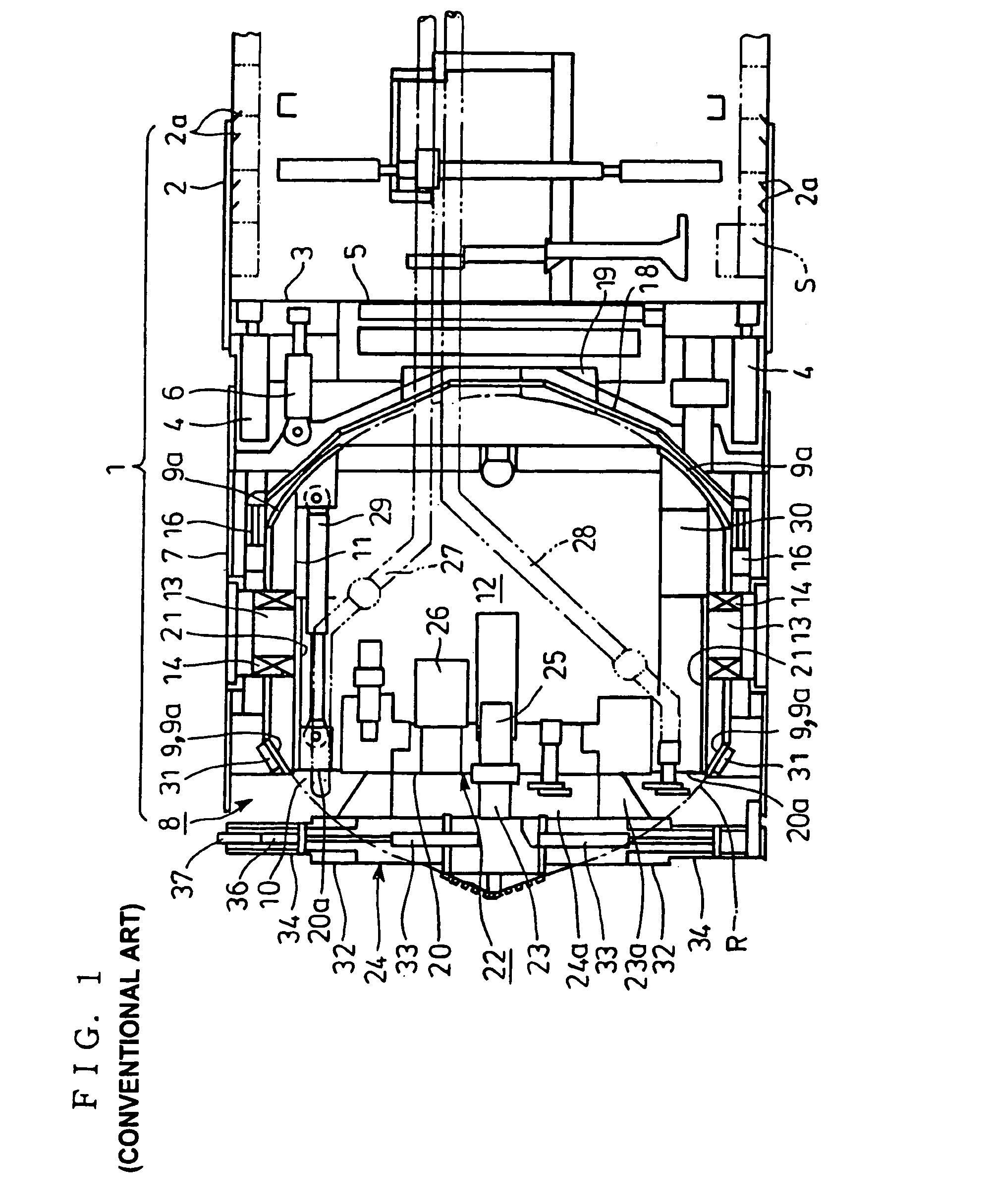

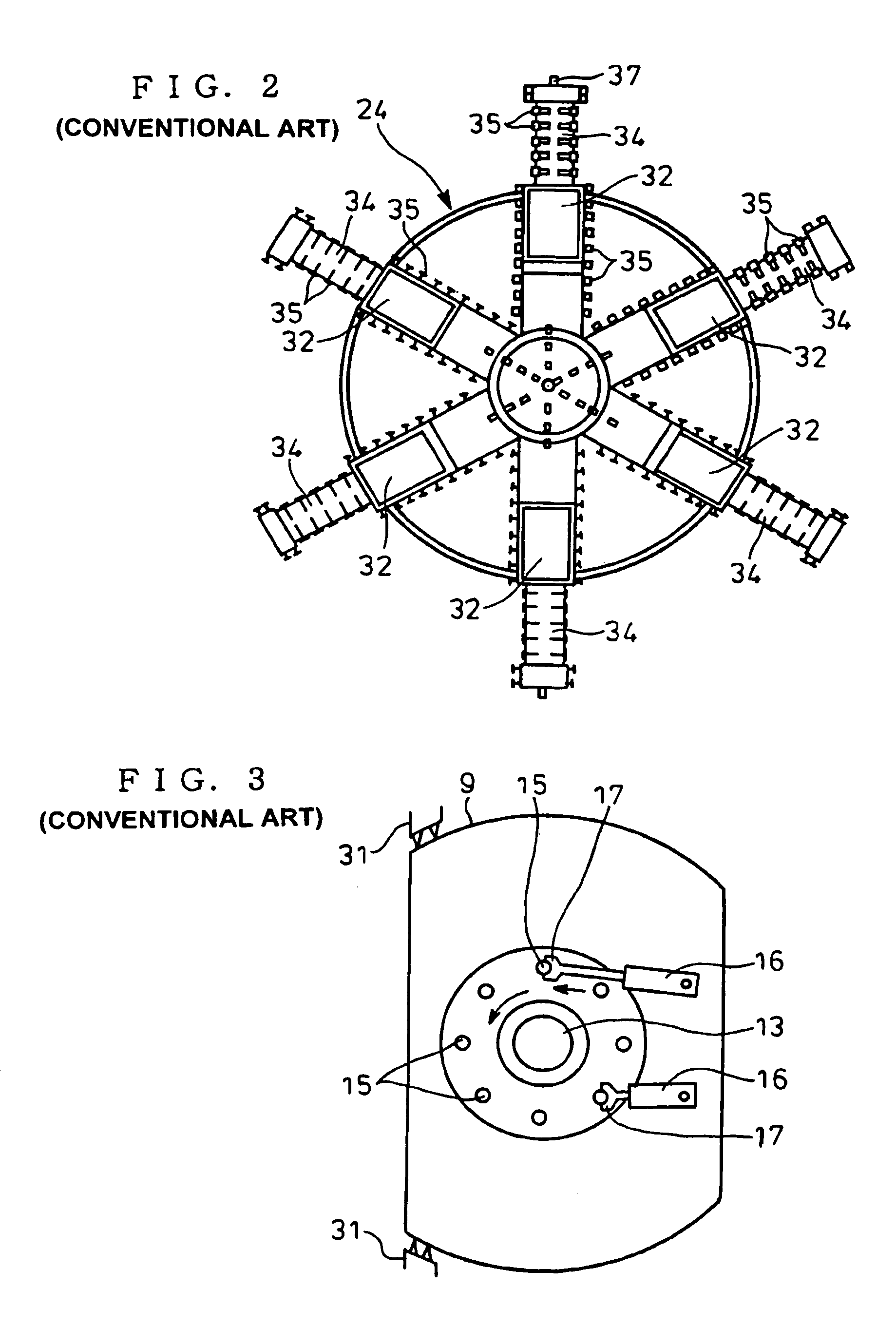

first embodiment

[0067]FIGS. 4 and 5 show a shield tunneling machine according to the invention in which a shield body 1 is illustrated to have a single skin plate 7; of course, it may alternatively have rear and front skin plates bendable at their connection just like the shield body 1 shown in FIG. 1. It is to be understood that the invention may have any type of shield body provided that a skin plate or plates have therein a turnable body in which an excavating drive is accommodated. The description will be made on the turnable body in the form of sphere; however, the turnable body may be of any shape such as a cylinder or a tube with a polygonal contour provided that it is turnable perpendicularly of the skin plate.

[0068]According to the first embodiment shown in FIGS. 4 and 5, a rotary shield device 8 has an excavating drive 22 with a cutter device 38 structurally different from the conventional cutter device 24 shown in FIGS. 1 and 2.

[0069]More specifically, disposed ahead of a rotor 20 rotate...

second embodiment

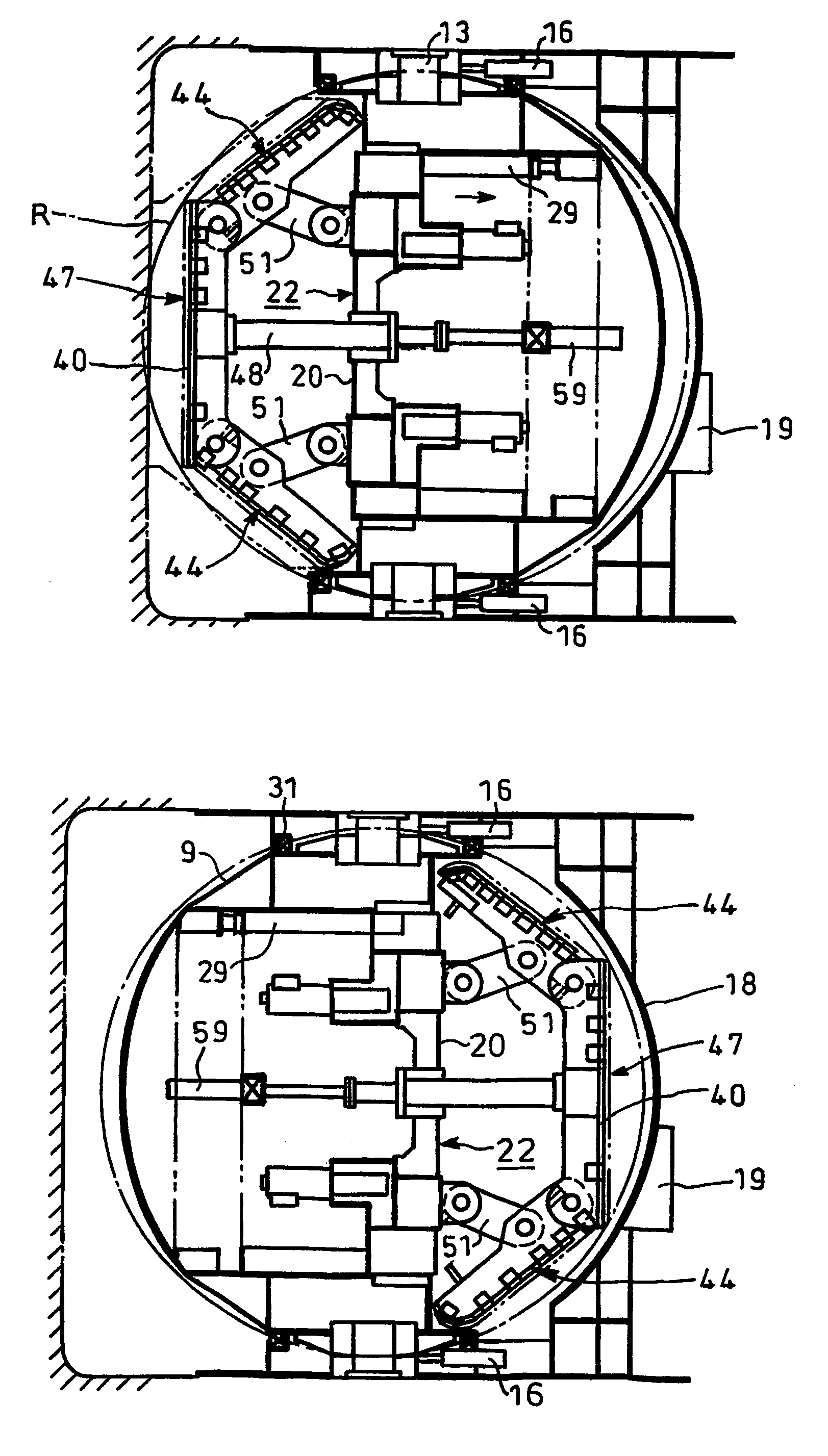

[0085]FIGS. 8 through 11 show a shield tunneling machine according to the invention.

[0086]The second embodiment has, as shown in FIGS. 8 and 9, a cutter device 47 which is ahead of an excavating drive 22 and which has a center shaft 48 movable backward / forward. The center shaft 48 has a rear end passing through the rotor 20 of the excavating drive 22 as well as a front end to which is fixed a face plate type center cutter 40 with a polygonal counter (an octagonal counter in FIG. 9). The center cutter 40 is shaped to be accommodated in the turning trajectory R of the turnable body 9 when it is retracted toward the excavating drive 22 as shown in FIG. 8. Alternatively, the center cutter 40 may have radially extending cutter frames 39 and substantially triangular face plates 41 with take-in slots 42 between the cutter frames 39 as shown in FIG. 5.

[0087]The polygonally countered center cutter 40 has outer edges having shafts 43 extending along the edges, respectively. Fitted to each of ...

third embodiment

[0110]FIGS. 16 through 22 show a shield tunneling machine according to the invention in which used in lieu of the stopper means in the form of the connectors 58 in the embodiment of FIGS. 8 through 11, is stopper means in the form of a peripheral ring 62 shaped to extend along the front end of the skin plate 7. Alternatively, such stopper means in the form of the peripheral ring 62 may be provided in addition to the stopper means in the form of the connectors 58 as shown in the embodiment of FIGS. 8 through 11.

[0111]The peripheral ring 62 is annular, and extends along the front end of the skin plate 7 as shown in FIGS. 17 through 19. There is provided in the front end of the skin plate 7 horizontal thrust jacks 63 each extending in the direction of tunneling. Each of the thrust jacks 63 has a tip end with a retaining jack 64 attached thereto and extending radially and inwardly of the shield body 1. Each of the retaining jacks 64 may be expanded and contracted to be fitted into and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com