Method of preparing a conjugated molecular assembly

a molecular assembly and conjugated technology, applied in the field of conjugated molecular assembly, can solve the problems of lack of order in polymeric thin films, inability to enable assembly onto surfaces, and inability to incorporate some of the desired molecular functionality, so as to improve electrical or sensor properties and wide range of functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

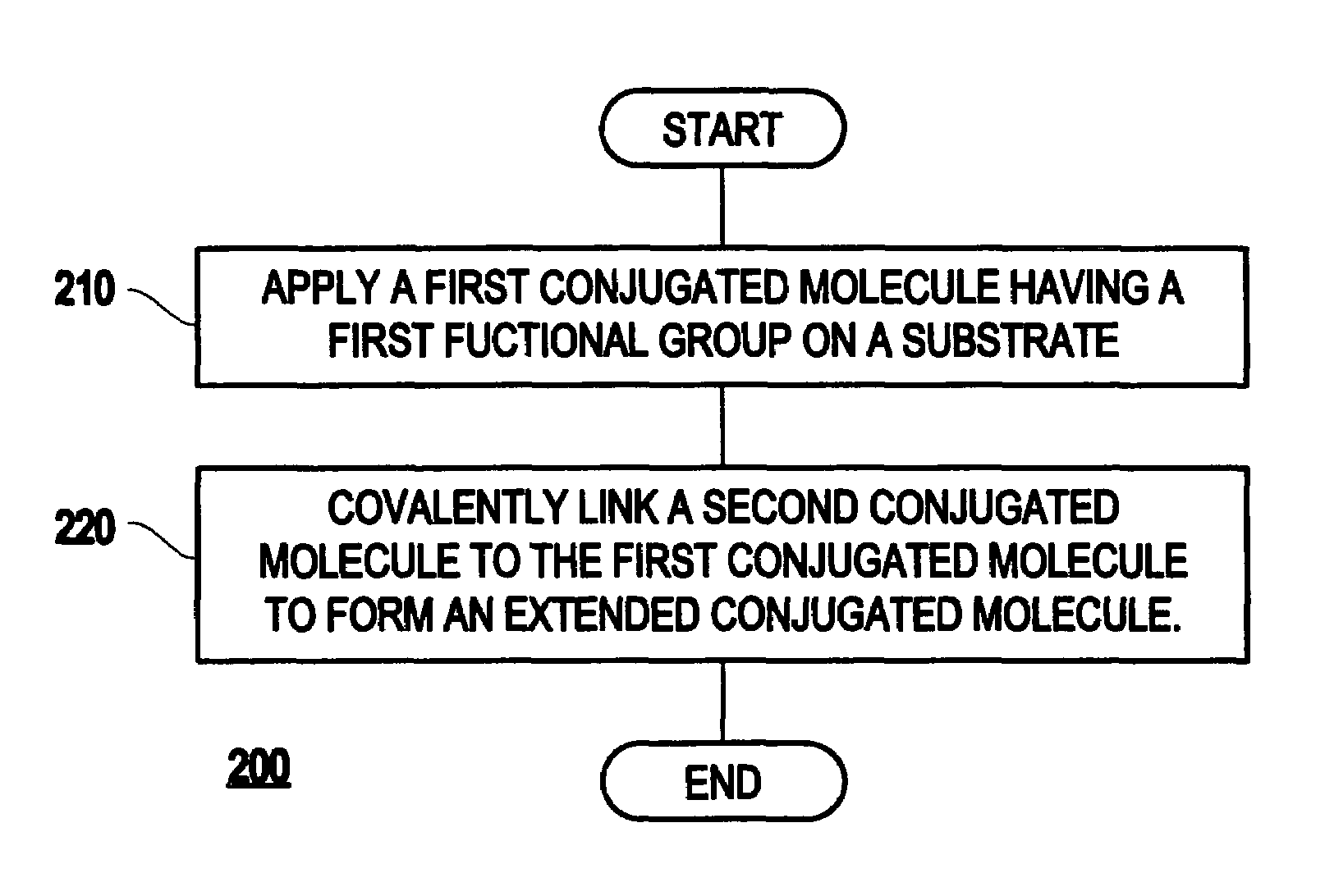

[0049]Referring now to the drawings, FIG. 1 illustrates a conjugated molecular assembly 100 according to the present invention. As shown in FIG. 1, the inventive molecular assembly 100 includes a substrate 110, and an extended conjugated molecule 120 which includes a first conjugated molecule 130 which is formed on the substrate 110, and a second conjugated molecule 140 which is covalently linked to the self-assembled monolayer 130. Further, a functional group 150 (e.g., a head functional group) may be used to attach (e.g., bond or adsorb) the first conjugated molecule to the substrate 110.

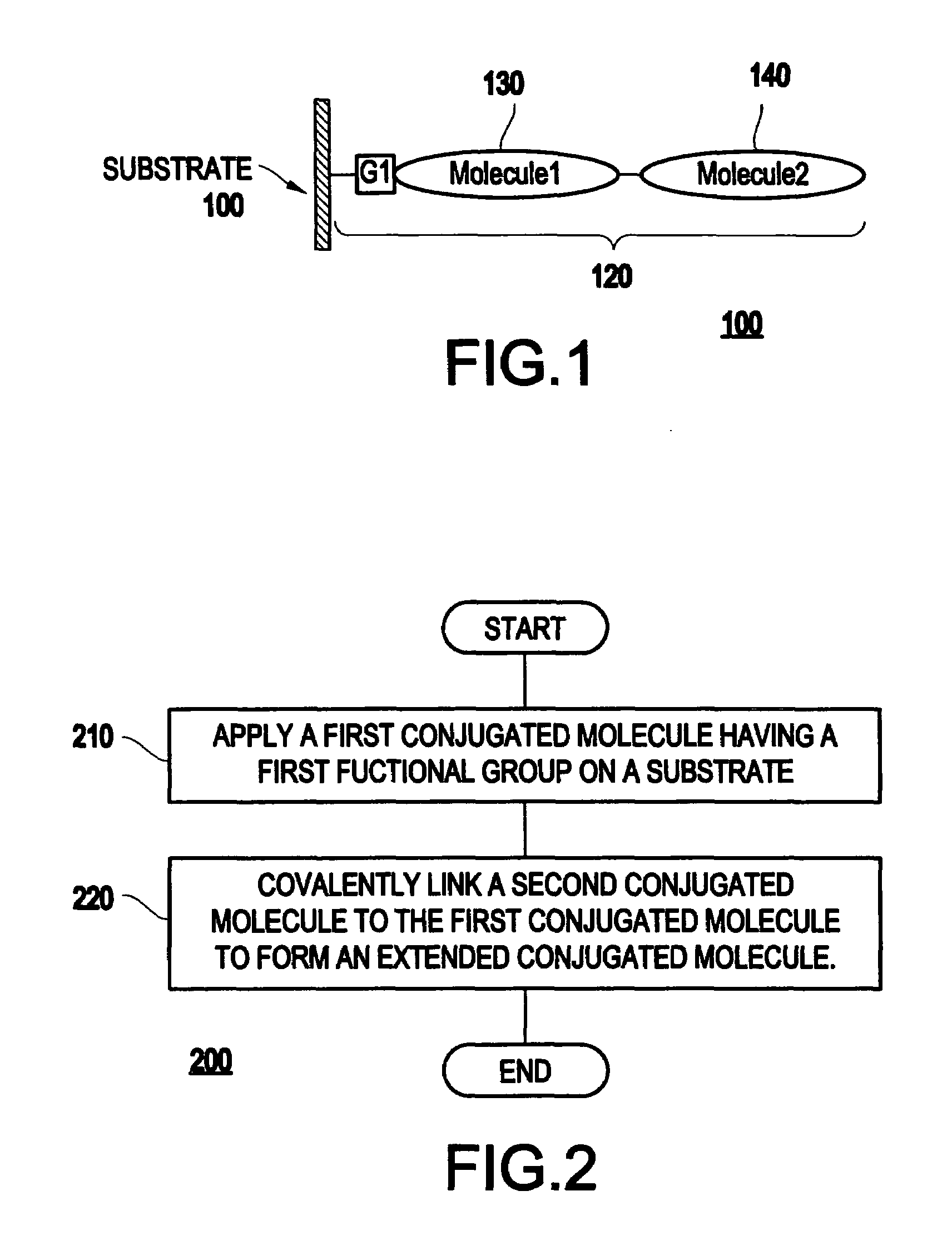

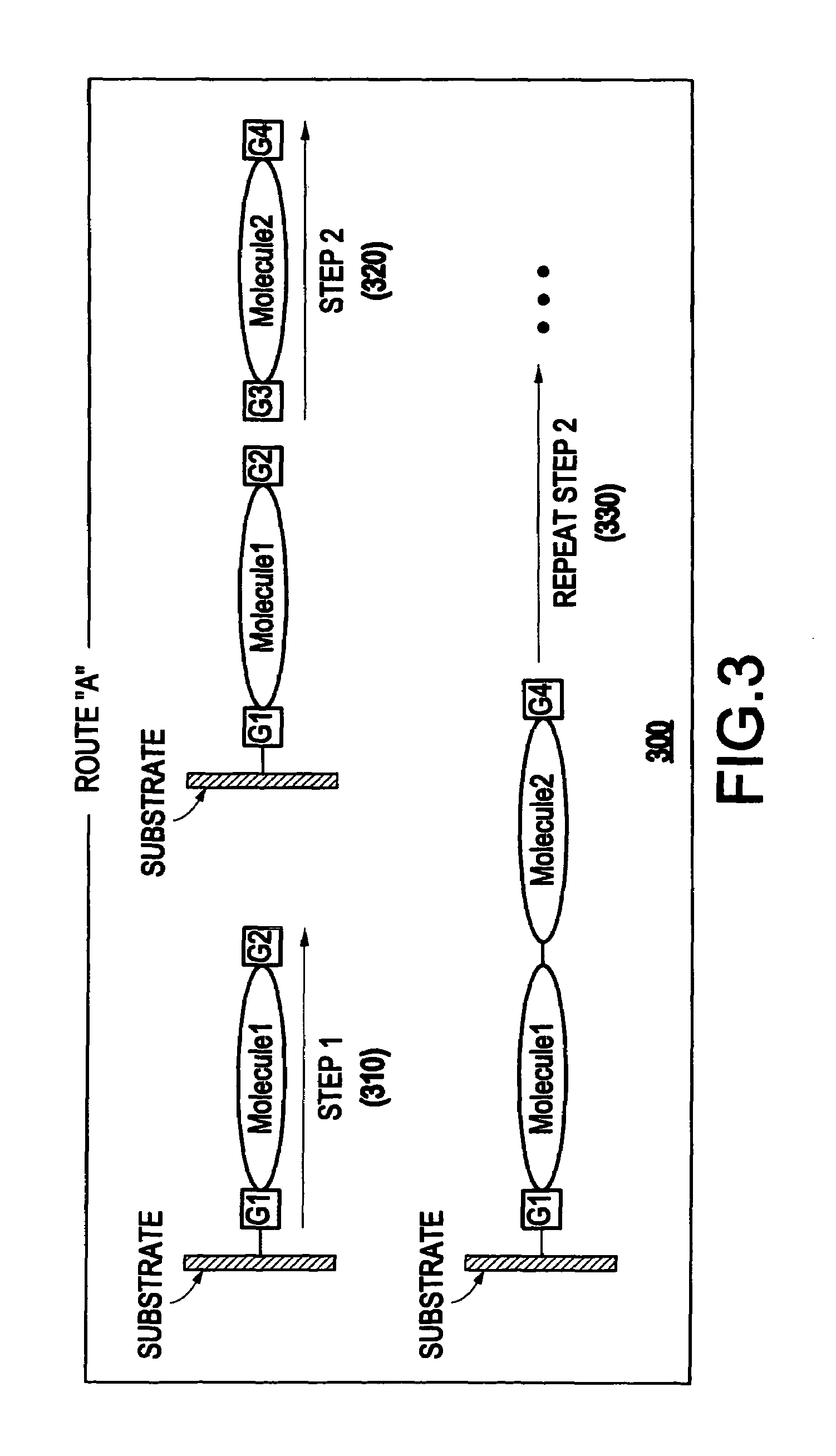

[0050]The present invention also includes an inventive method of fabricating a conjugated molecular assembly. As shown in FIG. 2, the inventive method 200 includes applying (210) a first conjugated molecule (e.g., having a first functional group) on a substrate, and covalently linking (220) a second conjugated molecule to the first conjugated molecule to form an extended conjugated molecule.

[0051]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| average molecular weight | aaaaa | aaaaa |

| intramolecular charge transport | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com