Programmably sliceable switch-fabric unit and methods of use

a switch fabric and programmable technology, applied in the field of switch fabrics, can solve the problems of high cost of 3232 parts, inability to meet the demands of such a demanding situation, and the low-speed crossbar design of 44 mentioned above, and achieve the effect of scalable throughput speed and fault tolerance, and increased traffic throughput rate for a given line card/uni

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

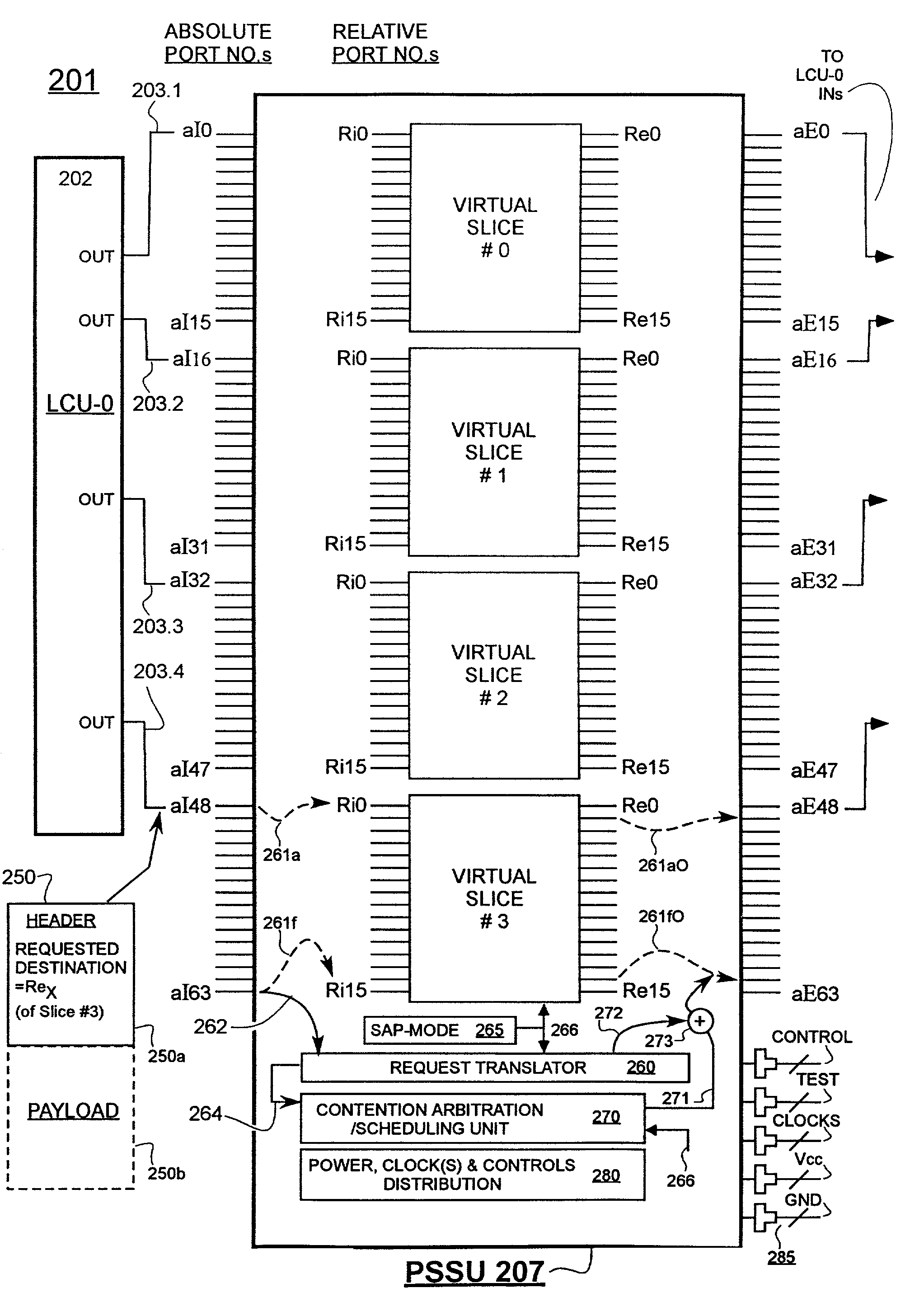

[0059]FIG. 1A is a workflow schematic for illustrating more clearly some of the industry problems described above. A first set (90) of parallel development paths 10, 20, . . . , 40 are illustrated as extending vertically to represent development and production cycles for different kinds of switch-fabric units (SFU's). Some overlap in shared technologies (e.g., integrated circuit fabrication processes) is of course possible between the illustrated parallel paths, 10-40.

[0060]One of the paths: 10, represents in downstream-directed order, the design-development, design-production, and supply-chain management phases of relatively simple class of SFU's, say, the 4×4 class of switch-fabric units. At the start of the 4×4 path 10, one or a variety of different 4×4 designs (11) may be created for servicing respective end-uses (100) that call for specific combinations of: (a) meeting a specified data throughput bandwidths, (b) complying with industry standard or proprietary interface protocol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com