Transparent combination package for cleaning, spin drying, displaying and storing a paint roller

a paint roller and combination package technology, applied in the field of transparent combination packages for cleaning, drying, displaying and storing paint rollers, can solve the problems of reducing the penetrating and spinning power available in normal domestic water systems, affecting the cleaning effect, so as to achieve the effect of quick cleaning, fluffed, and rendered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

A Transparent Combination Package for Cleaning, Spin Drying, Displaying, and Storing a PAINT ROLLER

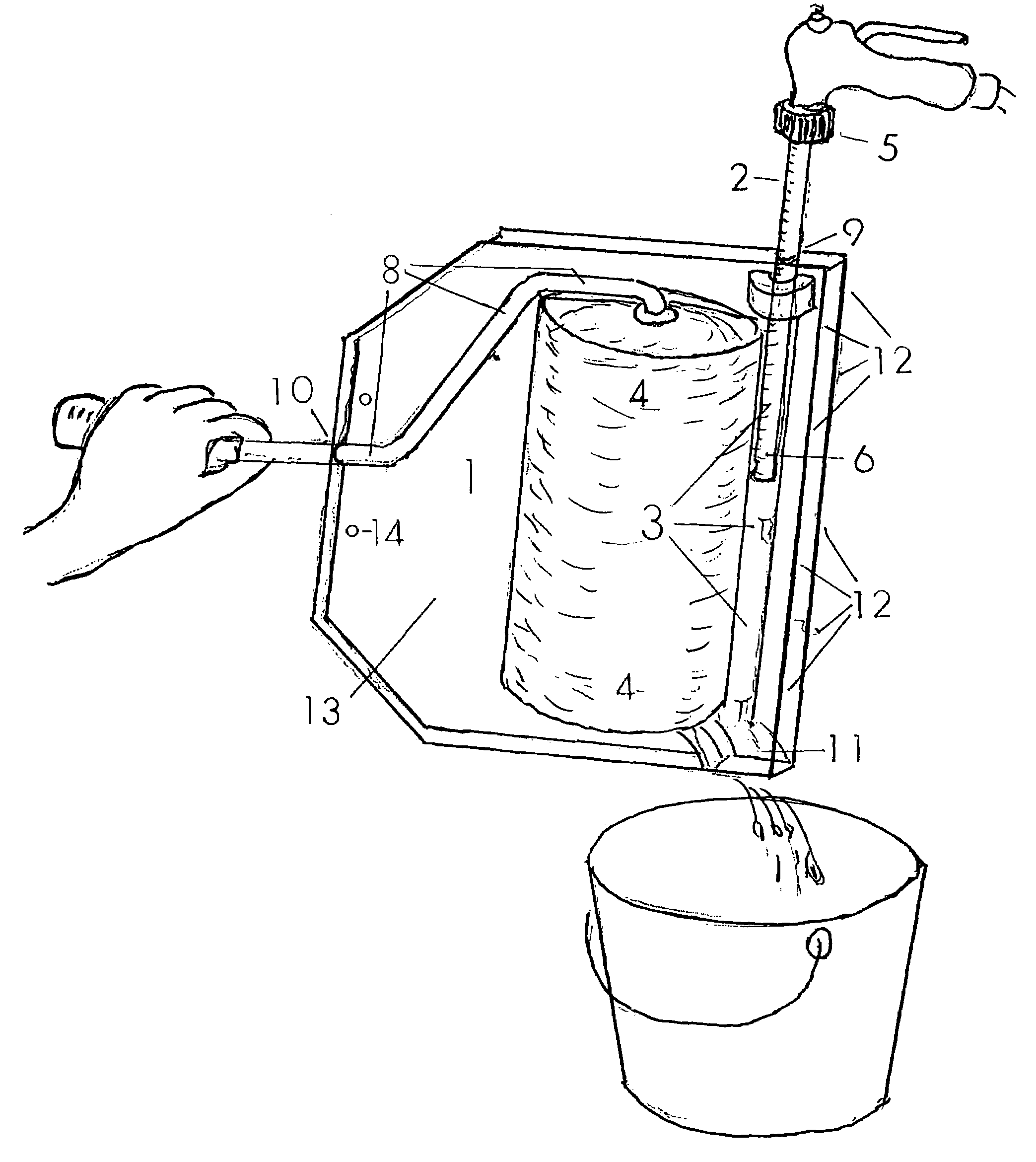

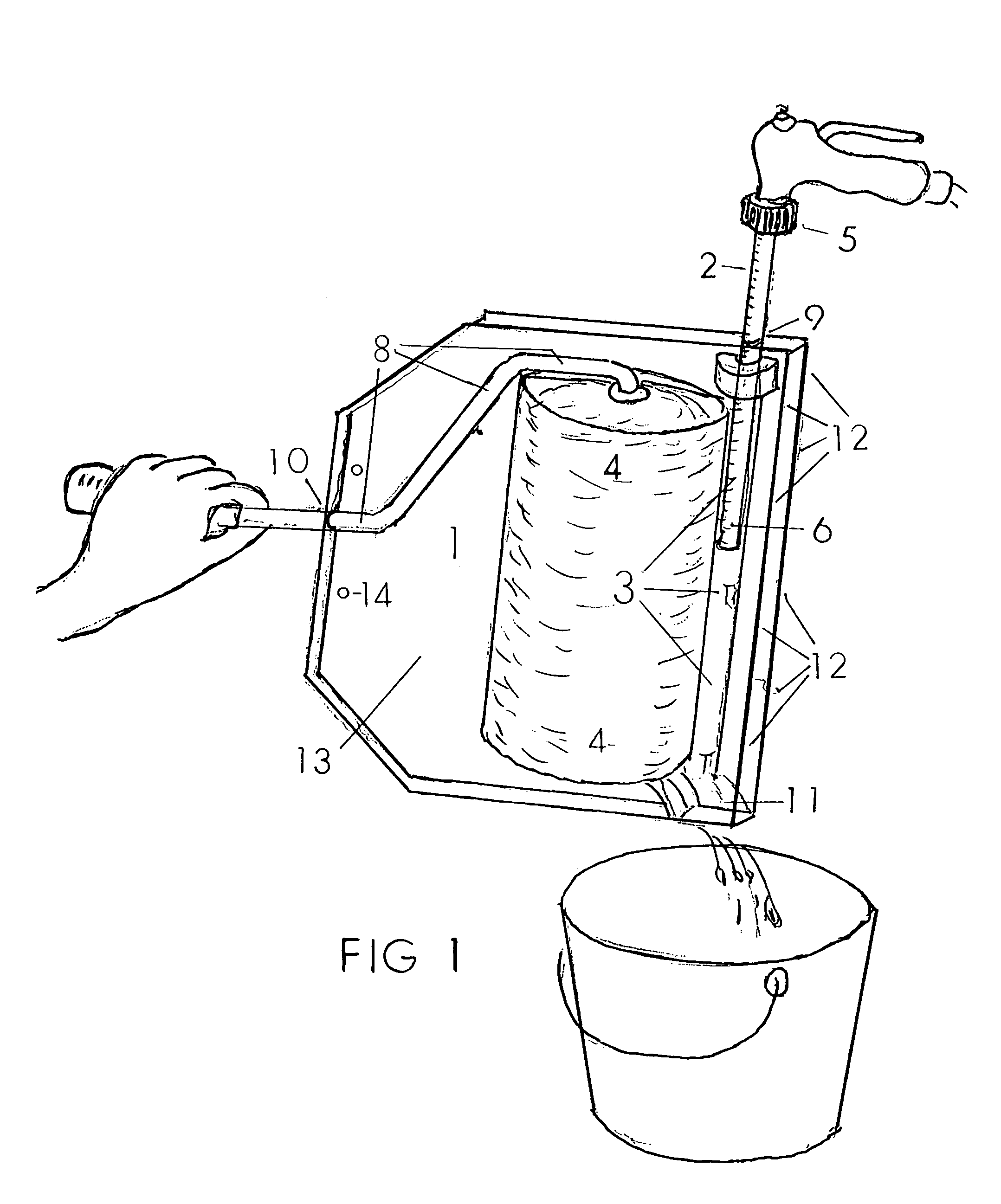

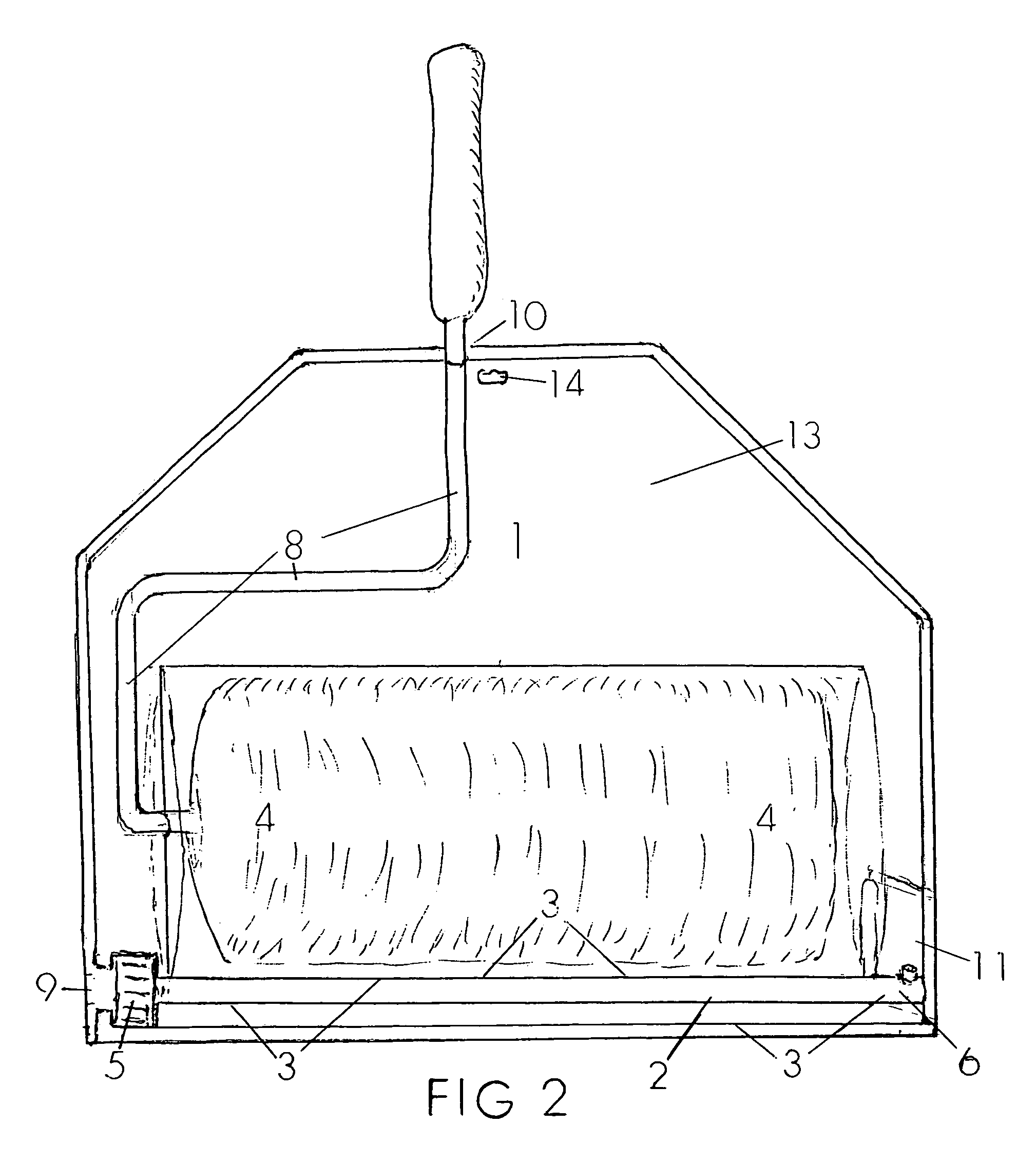

[0023]Disclosed herein is a device with four discrete functions relating to paint applicator tools known as paint rollers: first, it serves as a display package for a fully assembled paint roller; second, it functions as a cleaning or washing device for a paint roller; third, it functions as a spin-drying device for a paint roller; and finally, it serves as a storage package both for the device and for a paint roller.

[0024]This device has two components, a spray wand and a package or compartmented enclosure. One compartment of the package is designed to accommodate the spray wand for use, display and storage. A second compartment of the package is designed for containment of the processes of cleaning and spin drying, as well as for the display and storage of the paint roller.

[0025]The spray wand is a tubular device possessing a connection end and a spray delivery end. For use, the wand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com