Tool and a cutting insert for chip removing machining

a technology of cutting inserts and cutting edges, which is applied in the direction of cutting inserts, manufacturing tools, shaping cutters, etc., can solve the problems of reducing machining precision, affecting stability and position of cutting inserts, and affecting the cutting edge in relation to the basic body to such a large extent, so as to improve the interface, the effect of absorbing considerable cutting forces and the greatest need for stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

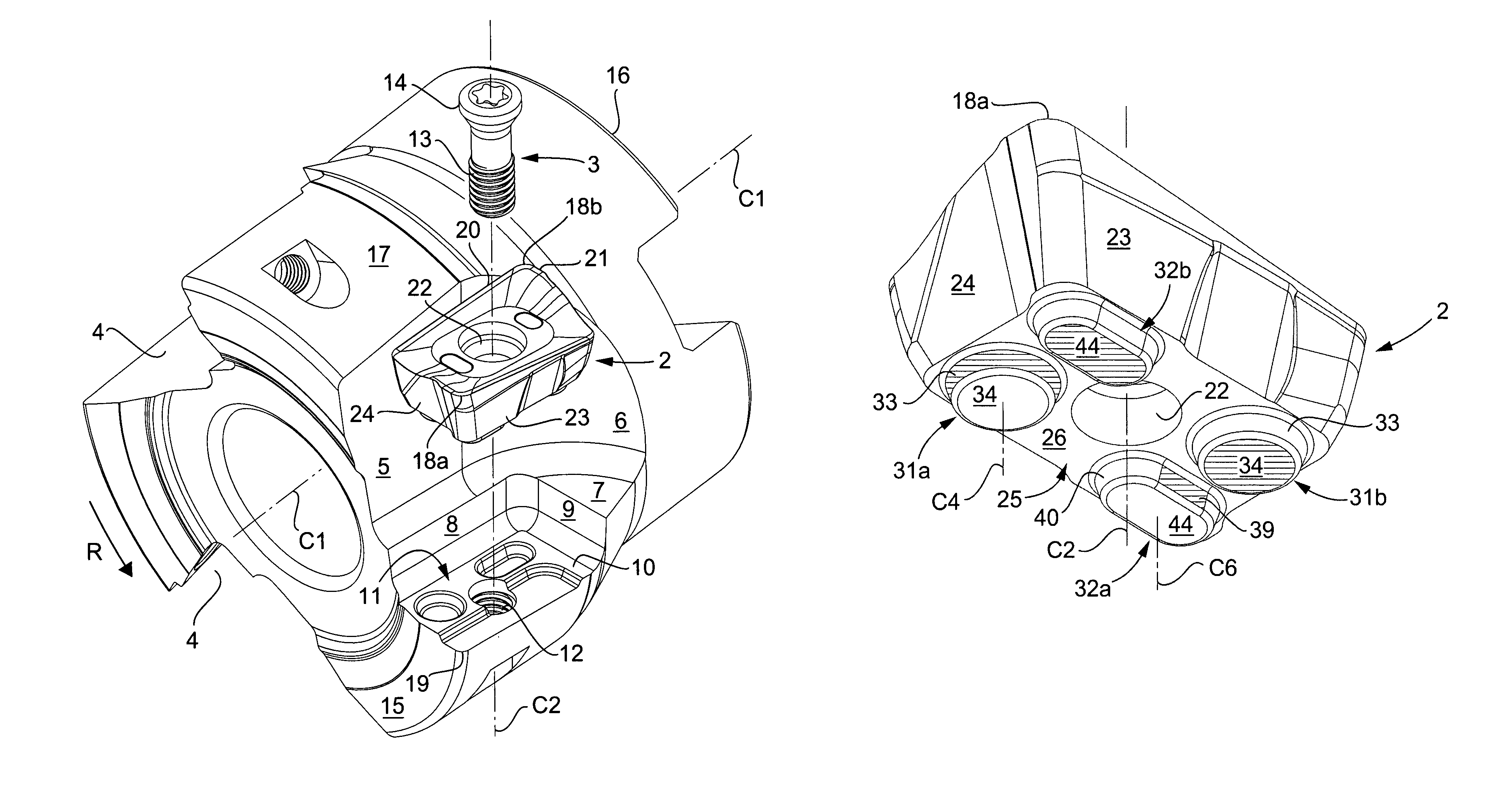

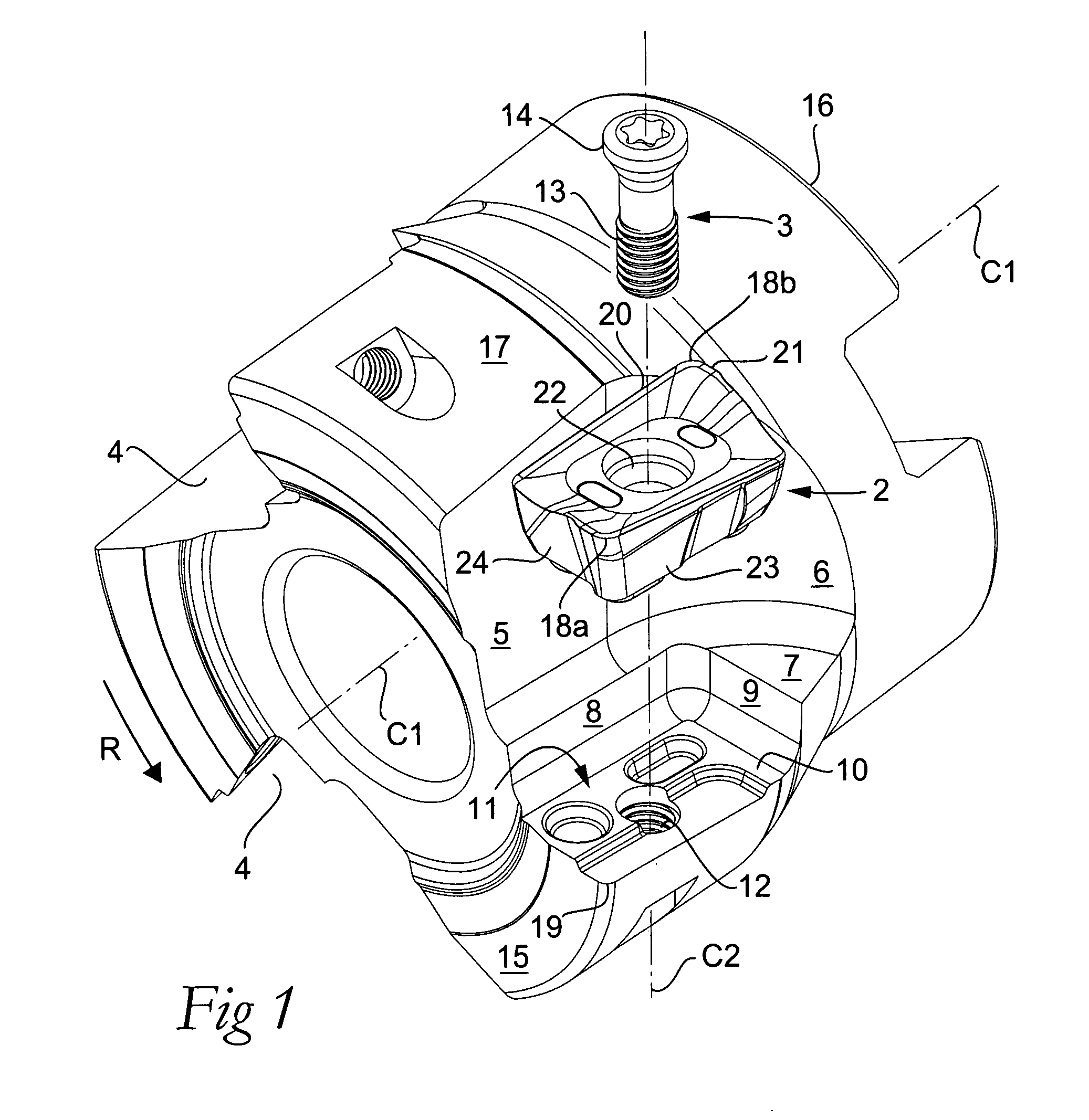

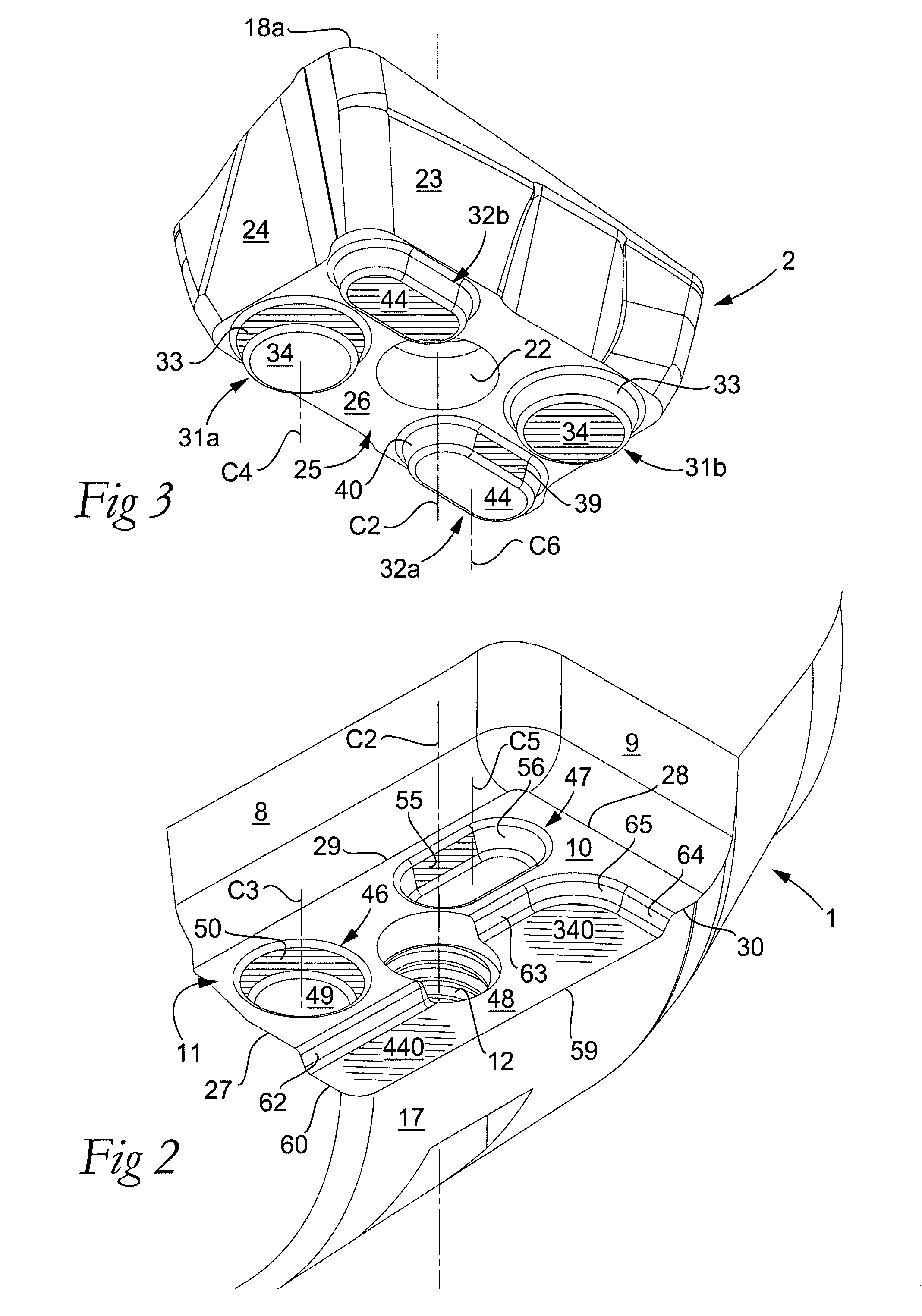

[0031]In FIG. 1, a tool for chip removing machining (cutting tool) is shown, which includes a basic body 1 and a cutting insert 2, that is fixable in the basic body by means of a tightening member 3, which, in this case, is in the form of a screw. In the example, the tool is rotatable and is a milling cutter, more precisely an end or face mill, which includes a plurality of chip pockets 4 in which equally many cutting inserts 2 can be mounted, only one of which is shown in FIG. 1. The basic body 1 is rotatable around a center axis designated C1.

[0032]In this case, the individual chip pocket 4 is delimited by a side surface 5, a concavely arched end surface 6, and a planar shoulder surface 7, which transforms into a countersink, which in turn is delimited by a side surface 8, an end surface 9, as well as a shoulder surface 10, which in this case is planar. Together with countersunk seatings and part surfaces, which will be described in detail below, the shoulder surface 10 is include...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cone angle | aaaaa | aaaaa |

| cone angle | aaaaa | aaaaa |

| cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com