Offshore oil-drilling rig and methods for installing same on an offshore oil-drilling site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

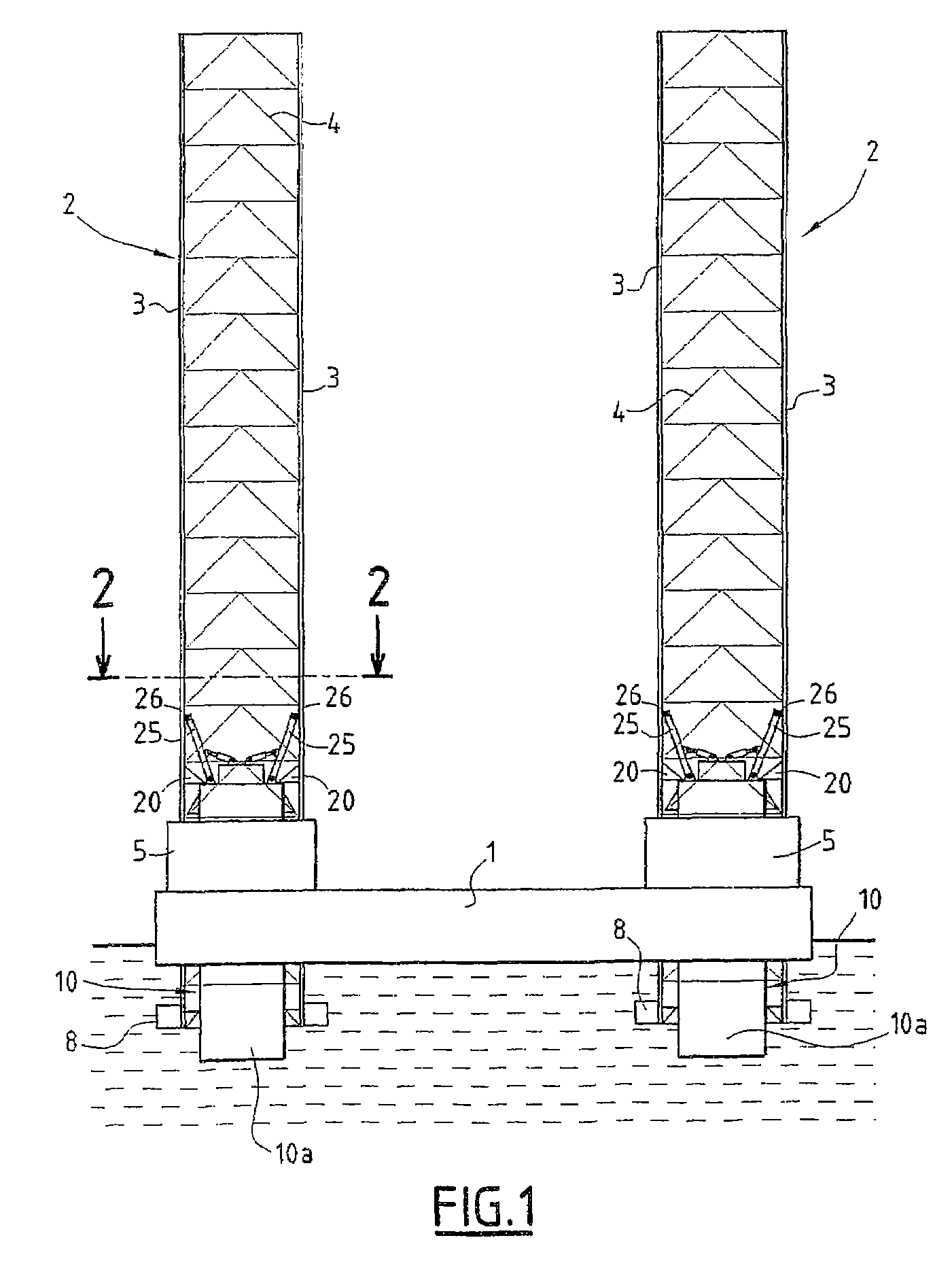

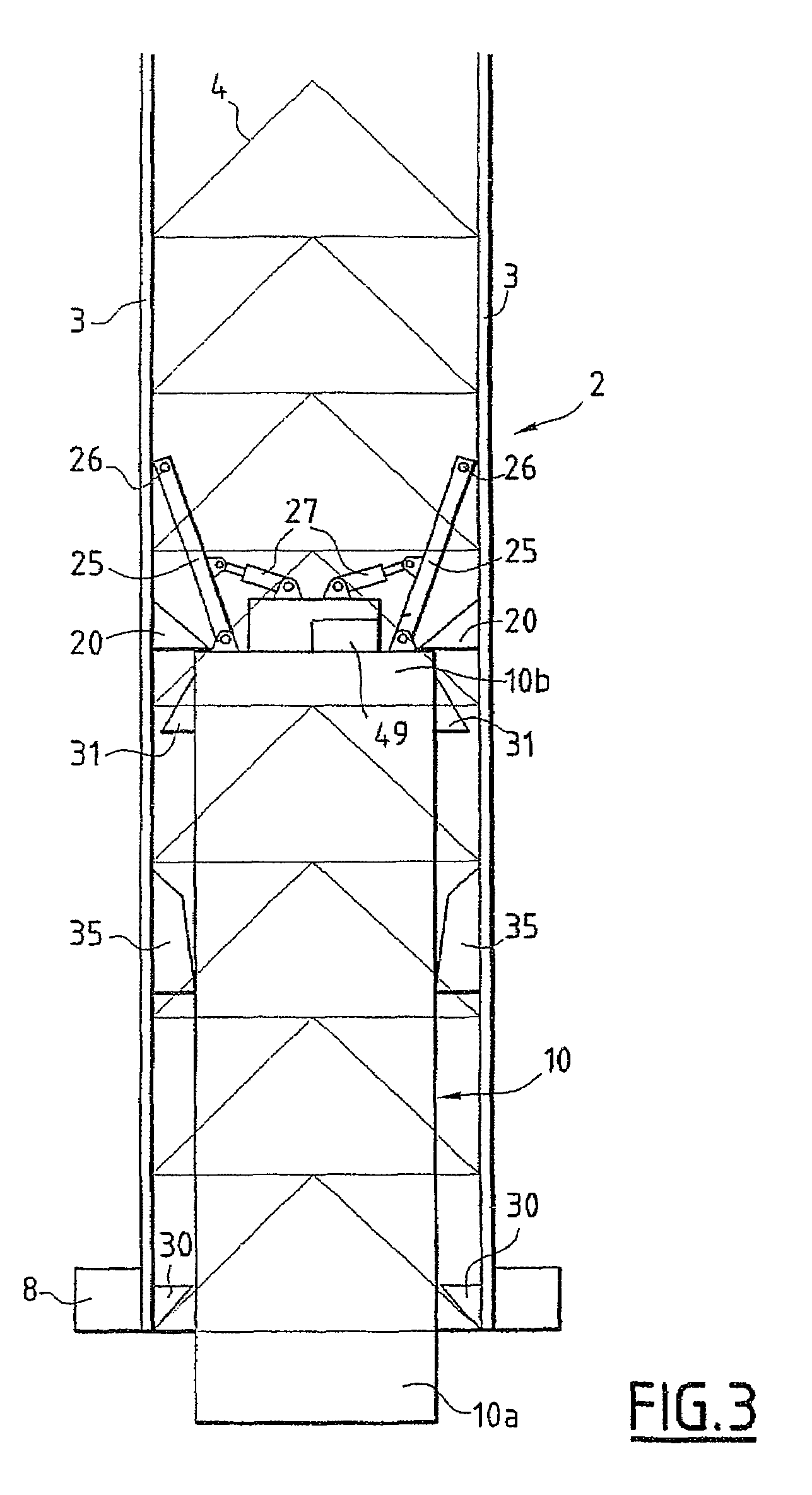

[0041]FIG. 1 illustrates schematically an offshore production, in particular a jackup, platform comprising a deck 1 provided with the usual production equipment and living premises.

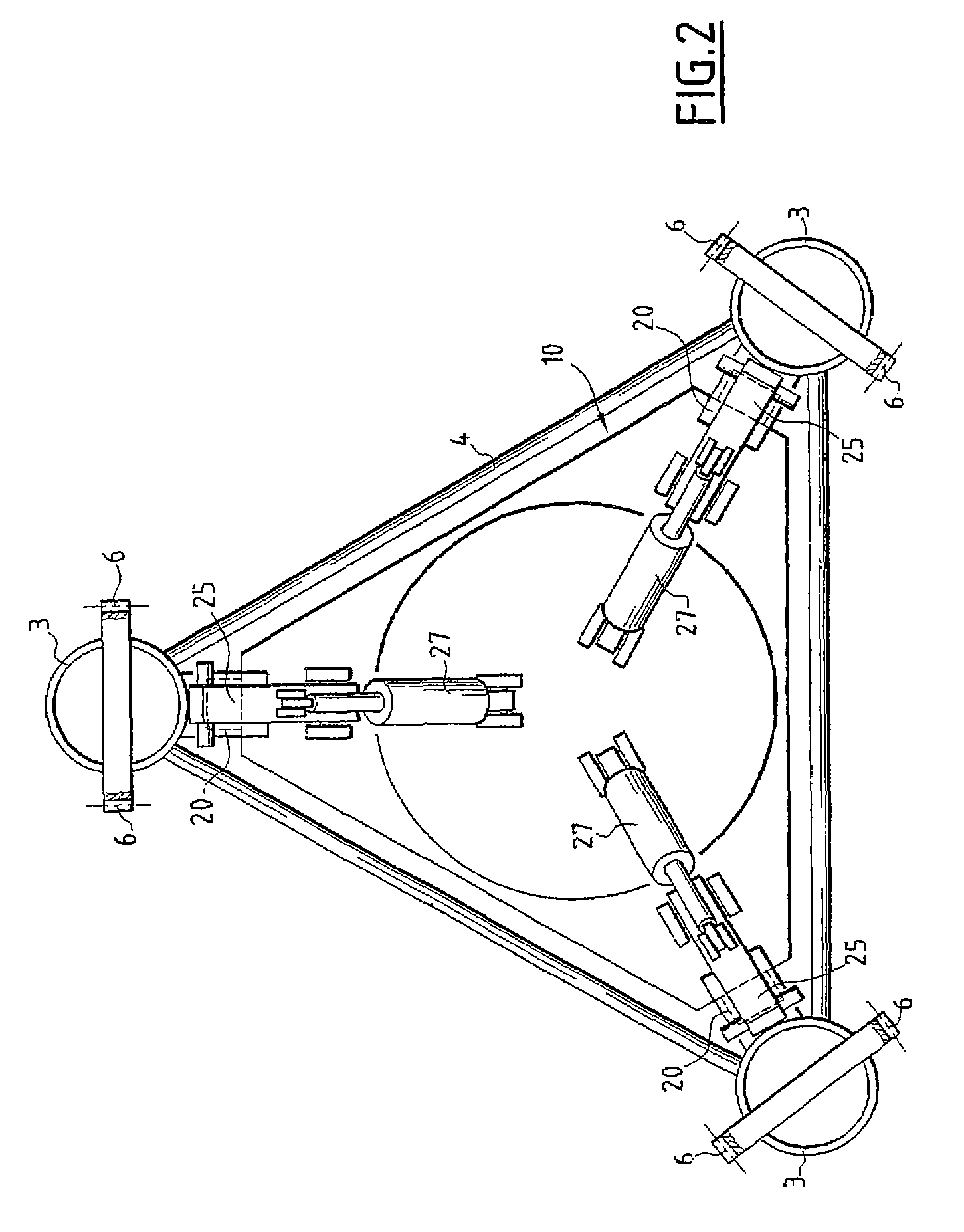

[0042]The deck 1 is moveably mounted on vertical legs 2, each of which is of triangular cross section, as shown in FIG. 2. These legs 2 can also be of square or circular cross section and they can number three or four, spaced uniformly on the deck 1.

[0043]FIG. 2 shows that each leg 2 is made up of three members 3 interconnected by a lattice of steel struts 4. Only two members 3 are shown in FIGS. 1, 6 and 7 for simplicity.

[0044]Movement of the deck 1 along the legs 2 is performed using drive mechanisms, not represented, located for each leg in a supporting framework 5, also called a “jackhouse” by specialists. Each supporting framework 5 is carried by the deck 1 and the drive mechanisms are conventionally formed of reduction gear units each driving an output pinion cooperating with racks 6 located on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com