Method and device for positioning ends of pipe sections relative to one another

a technology of pipe sections and ends, applied in the direction of pipe laying and repair, auxilary devices, application, etc., can solve the problems of high operational costs of pipe laying vessels, high time costs, and inability to achieve optimal connection between pipelines and pipes, etc., and achieve the effect of less tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

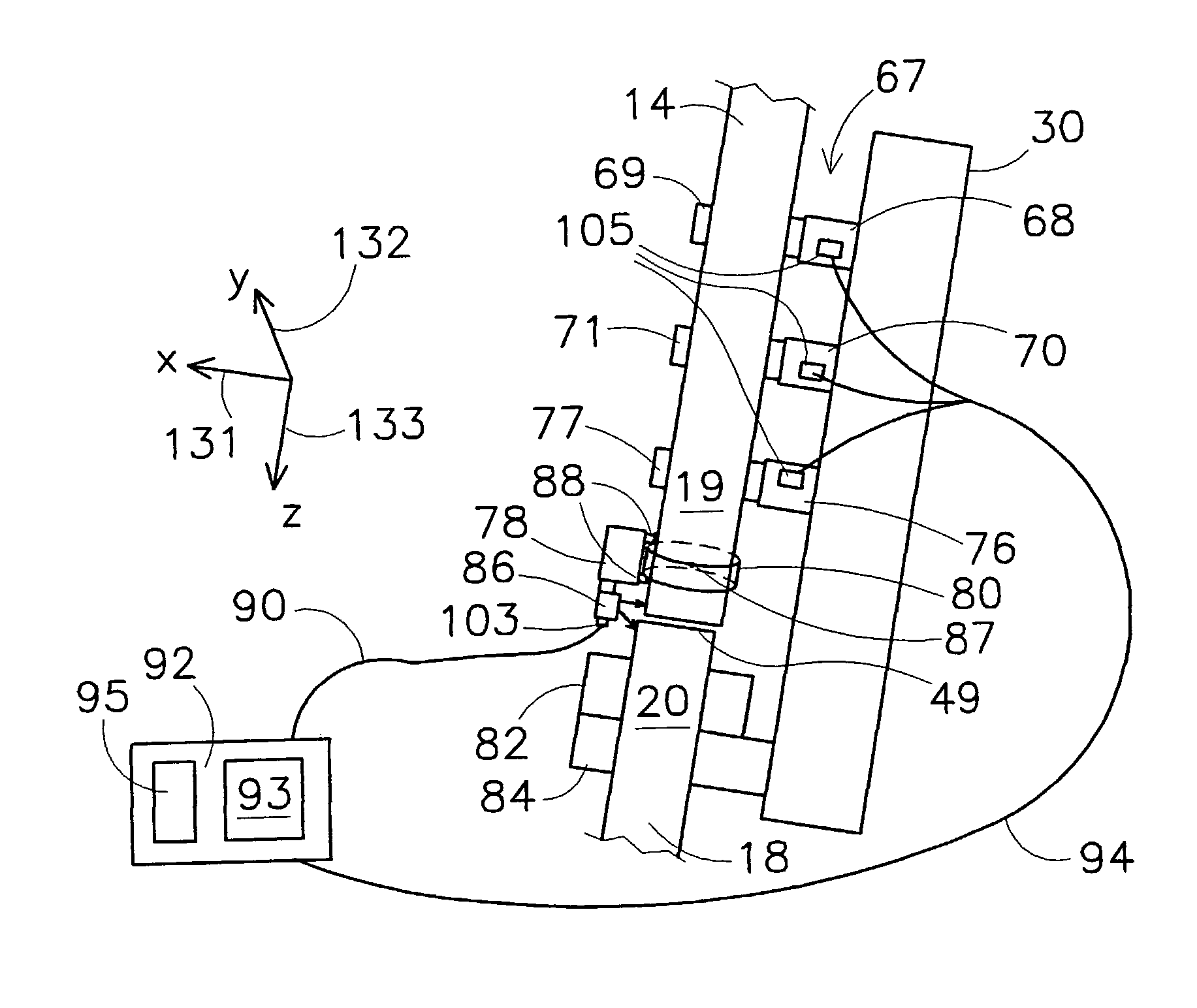

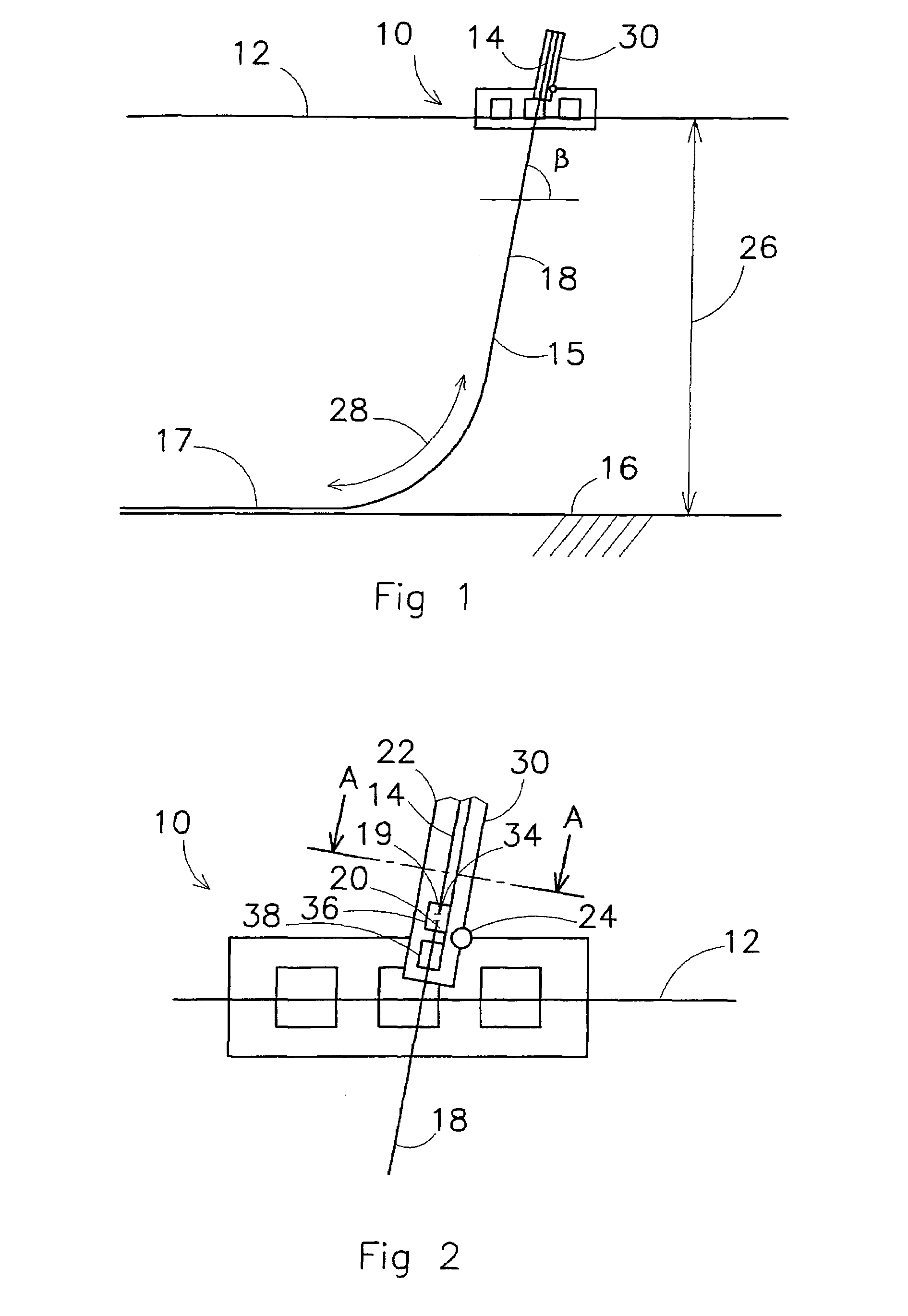

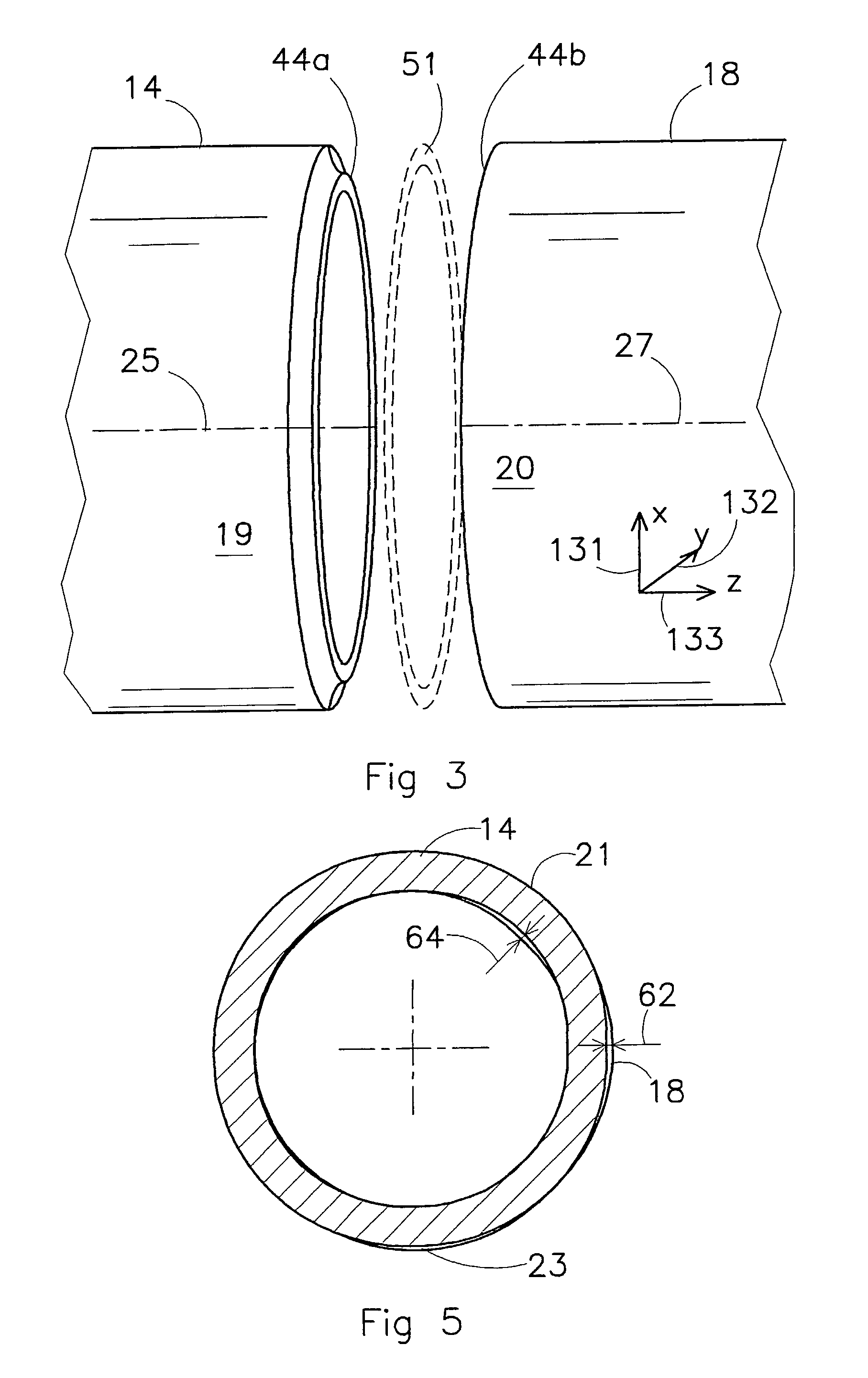

[0121]Referring to FIGS. 1 and 2, a pipe-laying vessel 10 is shown, which floats on a water surface 12. The pipe-laying vessel 10 comprises an inclined J-lay tower 30 which is connected by at least one hinge 24 to the pipe-laying vessel 10. The pipeline 18 is constructed by repeatedly welding pipe sections 14 to a free end 20 of the pipeline 18.

[0122]Depending on the water depth 26 and the submerged weight and stiffness of the pipeline 18, the tower 30 is set to an angle β with the horizontal, the angle β varying between 50 and 90 degrees.

[0123]During a J-lay operation, the pipeline 18 leaves the pipe-laying vessel 10 and extends in a J-shape between the pipe-laying vessel 10 and a seabed 16. A horizontal force is exerted on the free end 20 of the pipeline 18 by pipe-laying vessel 10 in order to prevent buckling of the pipeline 18 in the curved section 28 of the pipeline 18.

[0124]The process of adding a pipe section 14 to the pipeline 18 comprises a number of activities. First, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com