Penetrator bar for vertical tillage equipment

a technology of penetrator bars and vertical tillage, which is applied in the direction of agricultural machinery, drags, agricultural tools and machines, etc., can solve the problems of not being able to use coulter wheels, so as to increase the fracturing of soil, and effectively precondition the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

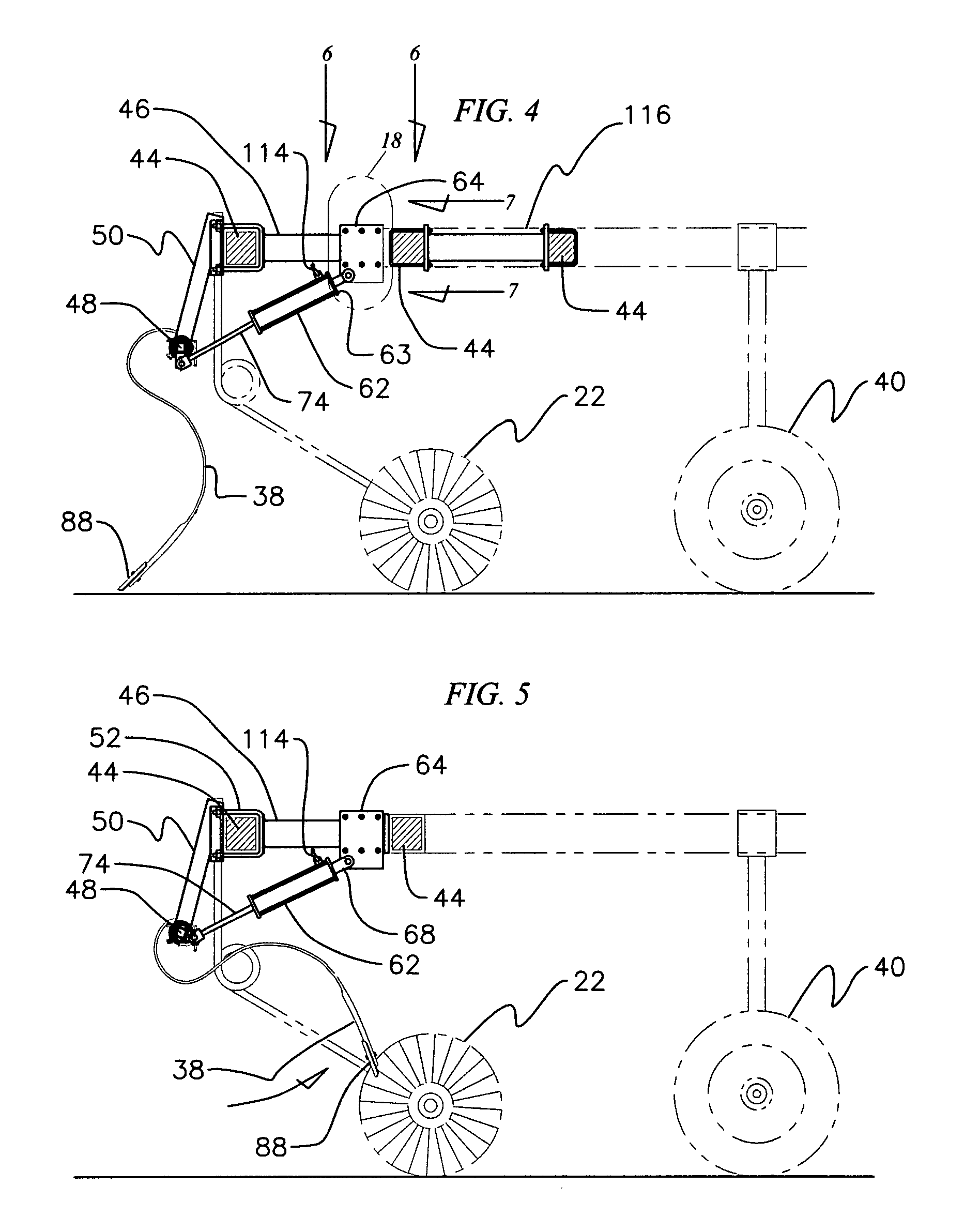

[0086]Reference is now made to the FIGs. discussed herein below wherein like numerals are used to refer to like features of the invention.

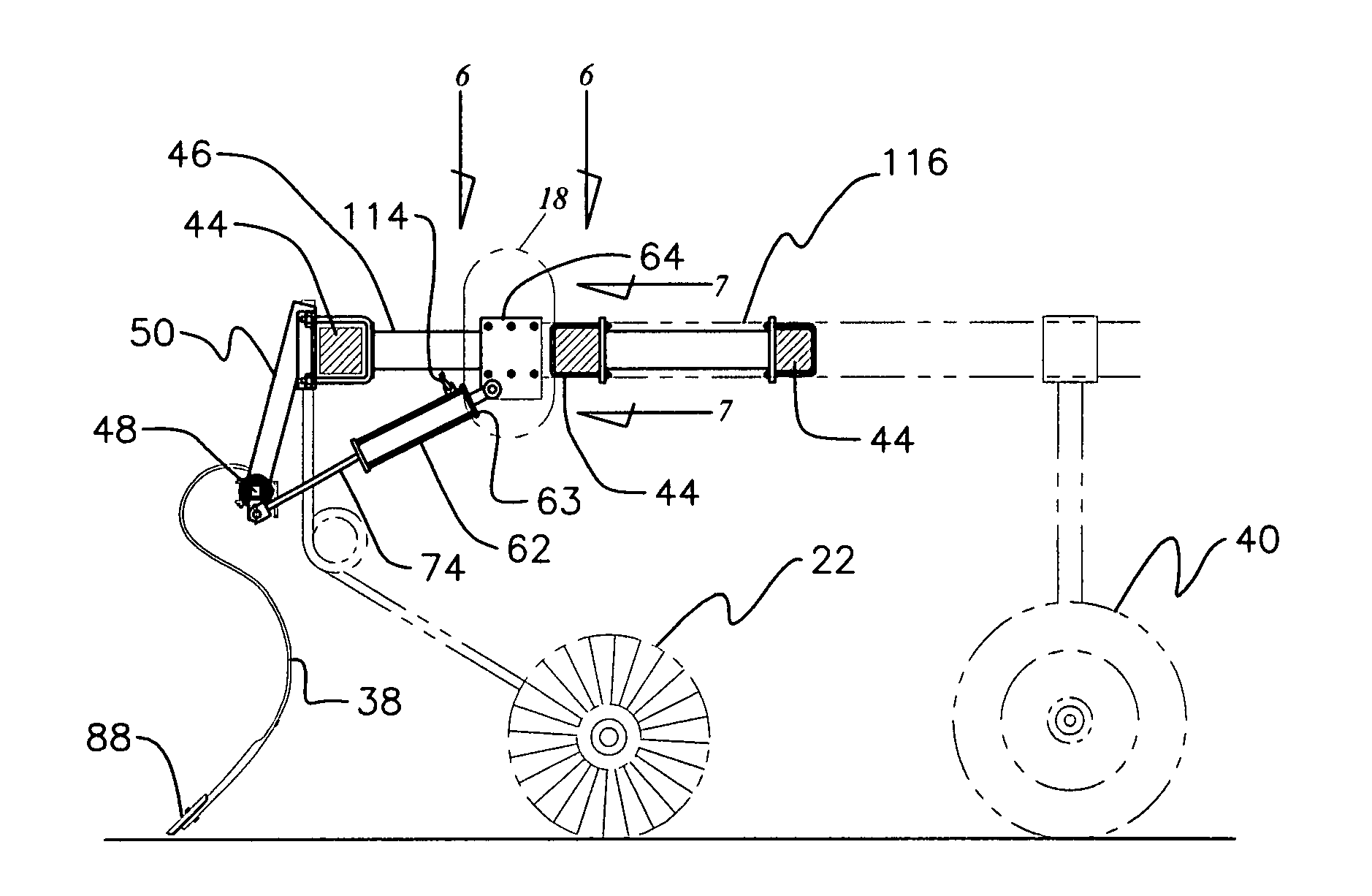

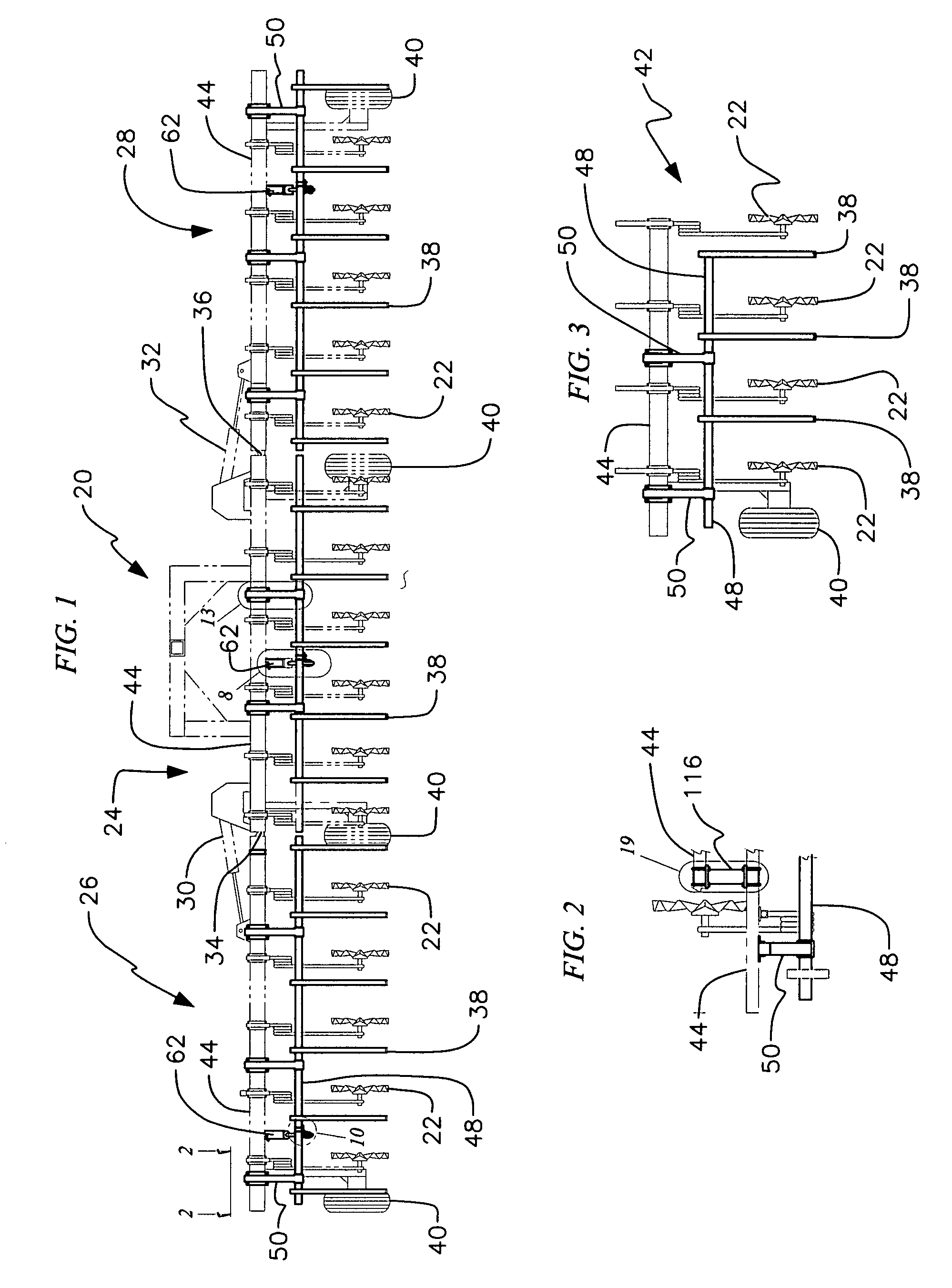

[0087]Referring to FIG. 1, there is disclosed a convention cultivation frame 20 with a plurality of coulter assemblies 22. The frame and coulter wheels are disclosed in dashed lines. The particular components of the present invention are disclosed in bolded fashion. It may be appreciated that in large farming operations, the cultivation equipment is quite large to enable the user to cover many acres of ground in a shorter time. The conventional cultivator frame 20 disclosed in FIG. 1 may be seen to have a center portion 24, a left wing portion 26 and a right wing portion 28. Hydraulic apparatus 30 may be activated to cause left portion 26 of the tillage equipment 20 to be winged up to a nearly vertical position at left hinge 34. Likewise, hydraulic apparatus 32 may be activated to cause right portion 28 of tillage implement to rotate about right h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com