Power output apparatus and hybrid vehicle

a technology of power output apparatus and hybrid vehicle, which is applied in the direction of hybrid vehicle, gearing, electric propulsion mounting, etc., can solve the problems of difficulty in applying the power output apparatus of this structure to a front wheel drive vehicle, and the vehicle is not suitably mounted on the vehicle, so as to improve fuel consumption, improve power transmission efficiency, and facilitate driving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]Some modes of carrying out the invention are described below as preferred embodiments.

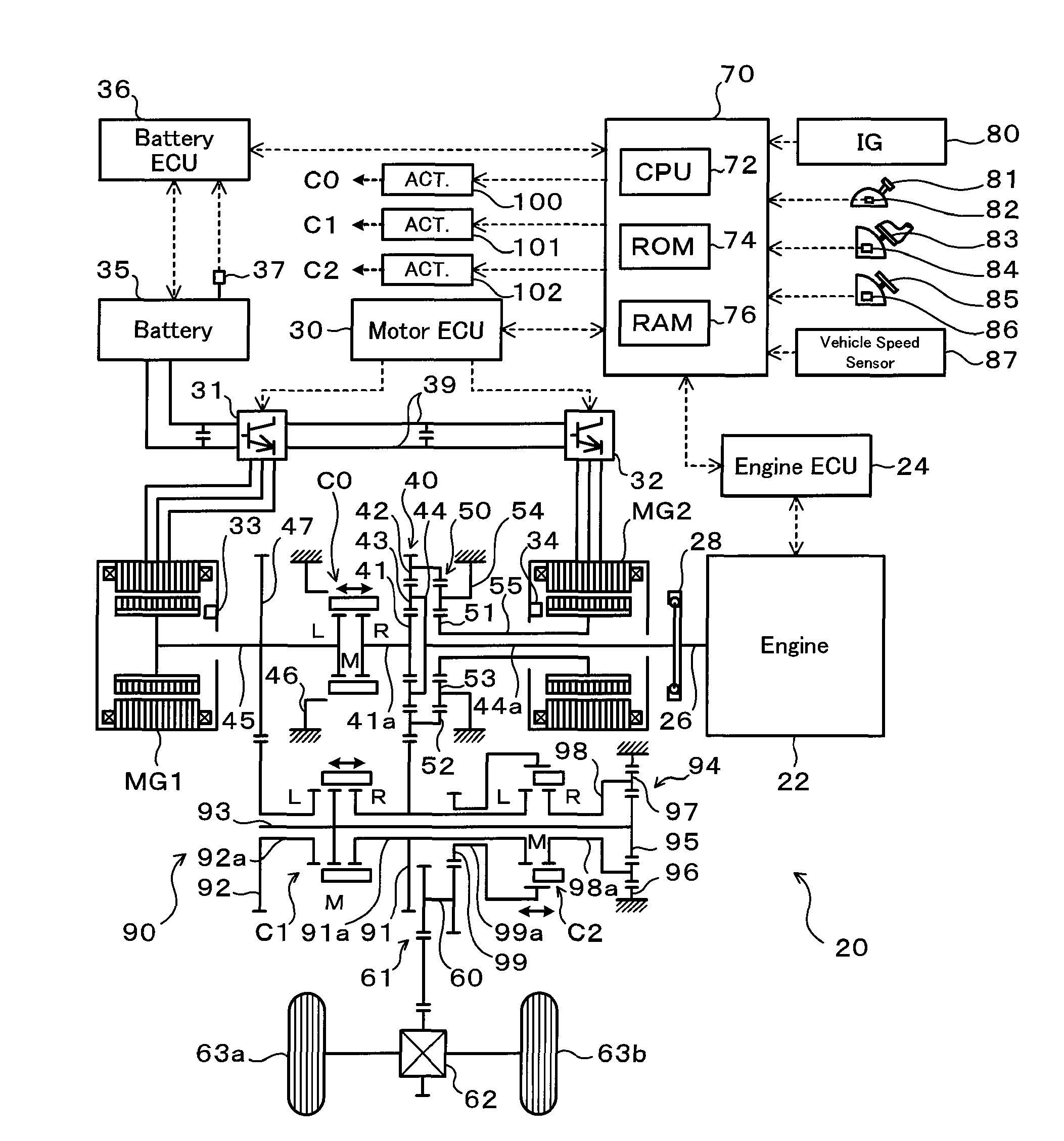

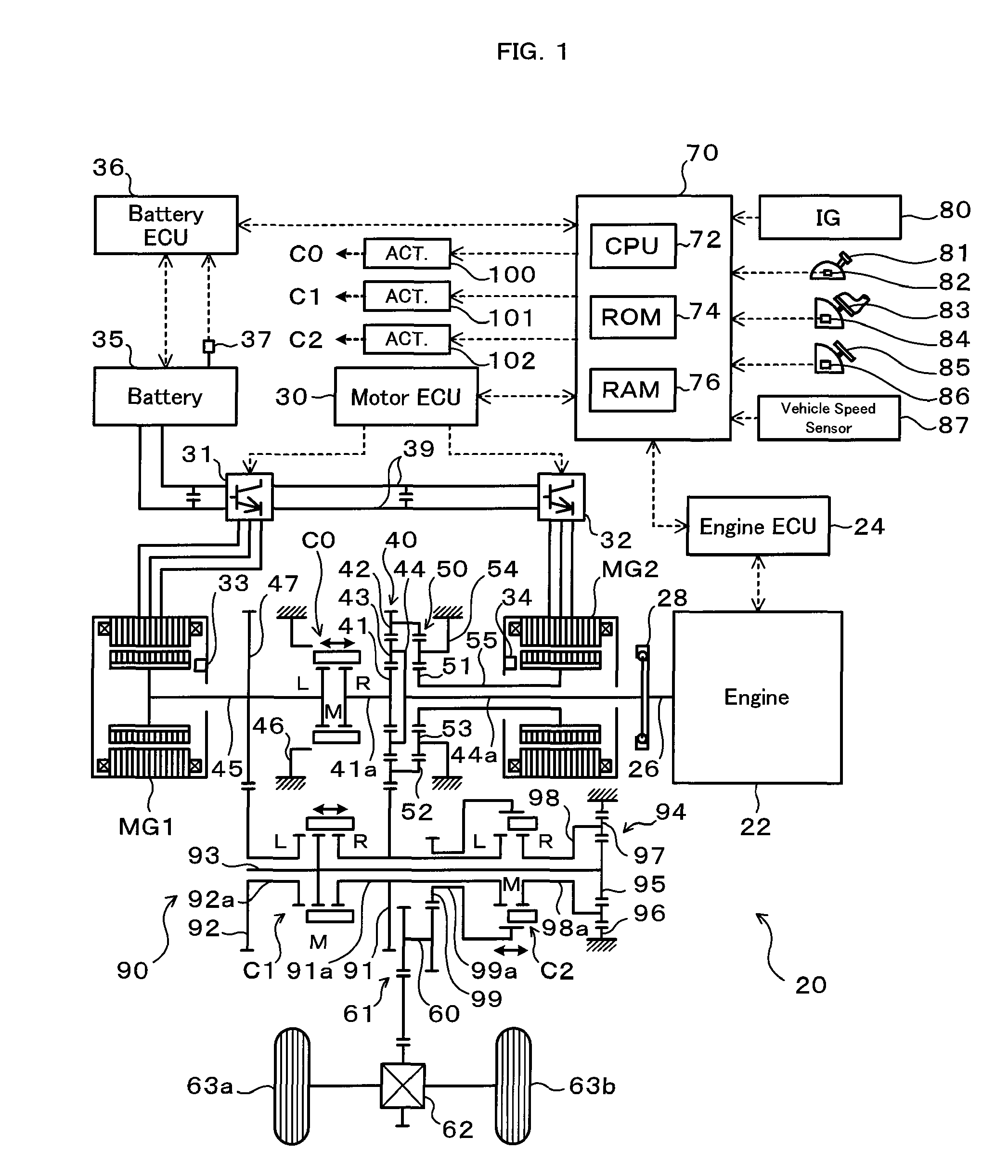

[0038]FIG. 1 schematically illustrates the configuration of a hybrid vehicle 20 in an embodiment of the invention. The hybrid vehicle 20 shown in FIG. 1 is constructed as a front-wheel drive vehicle and includes an engine 22 located in a front portion of the vehicle, a power distribution integration mechanism (differential rotation mechanism) 40 connected with a crankshaft 26 or an output of the engine 22, a motor MG1 arranged coaxially with the crankshaft 26 of the engine 22 and connected with the power distribution integration mechanism 40 and designed to have power generation capability, a motor MG2 arranged coaxially with the engine 22 and the motor MG1 to be connected with the power distribution integration mechanism 40 via a reduction gear mechanism 50 and designed to have power generation capability, a transmission 90 constructed to transmit the output power of the power distribution i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com