Laminator with changeable rotation speed and heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066]Each of a first specific embodiment and a second specific embodiment according to the present invention provides a laminator with changeable rotation speed and heating temperature, which is capable of laminating two films with different thickness and an object disposed there between.

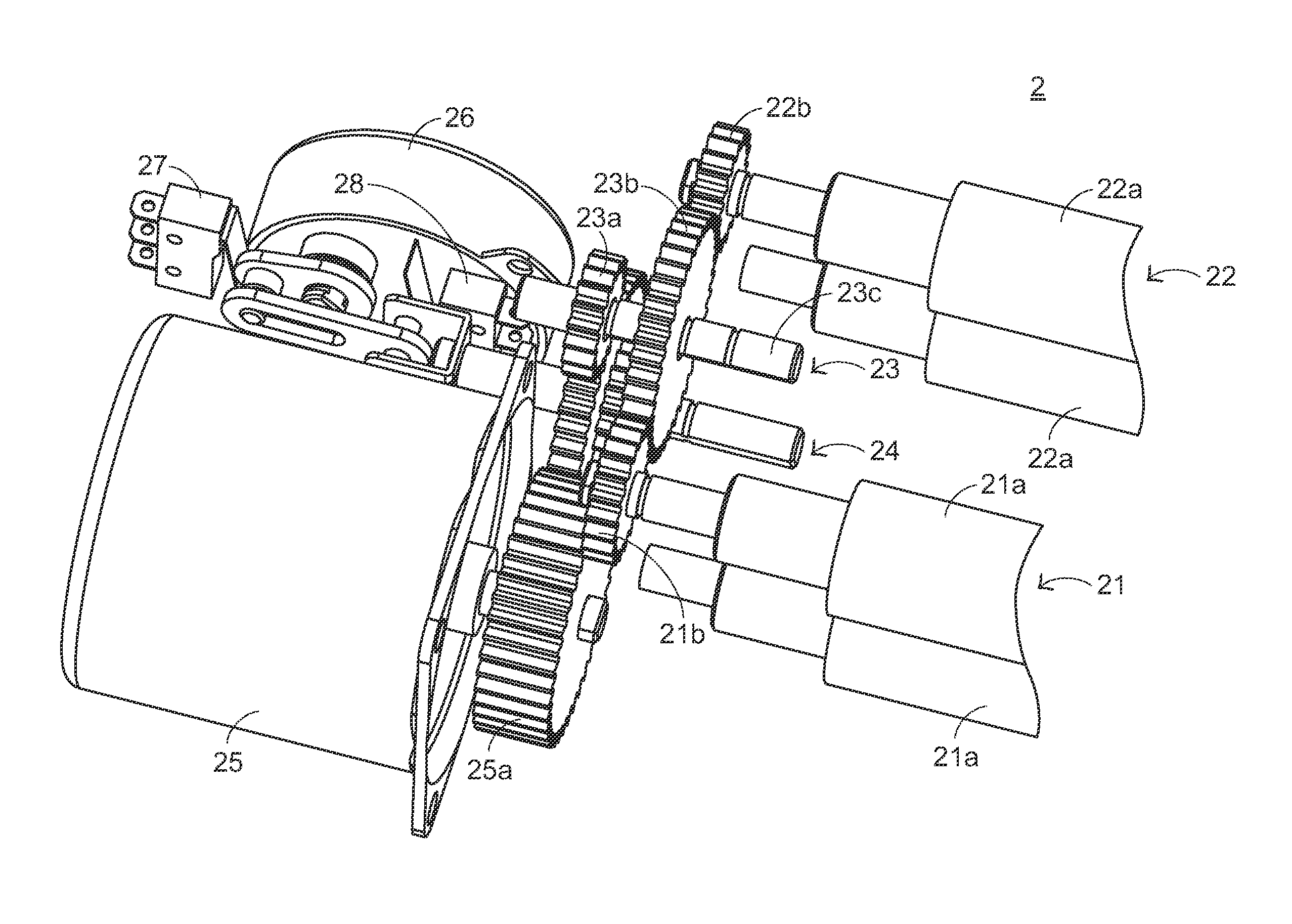

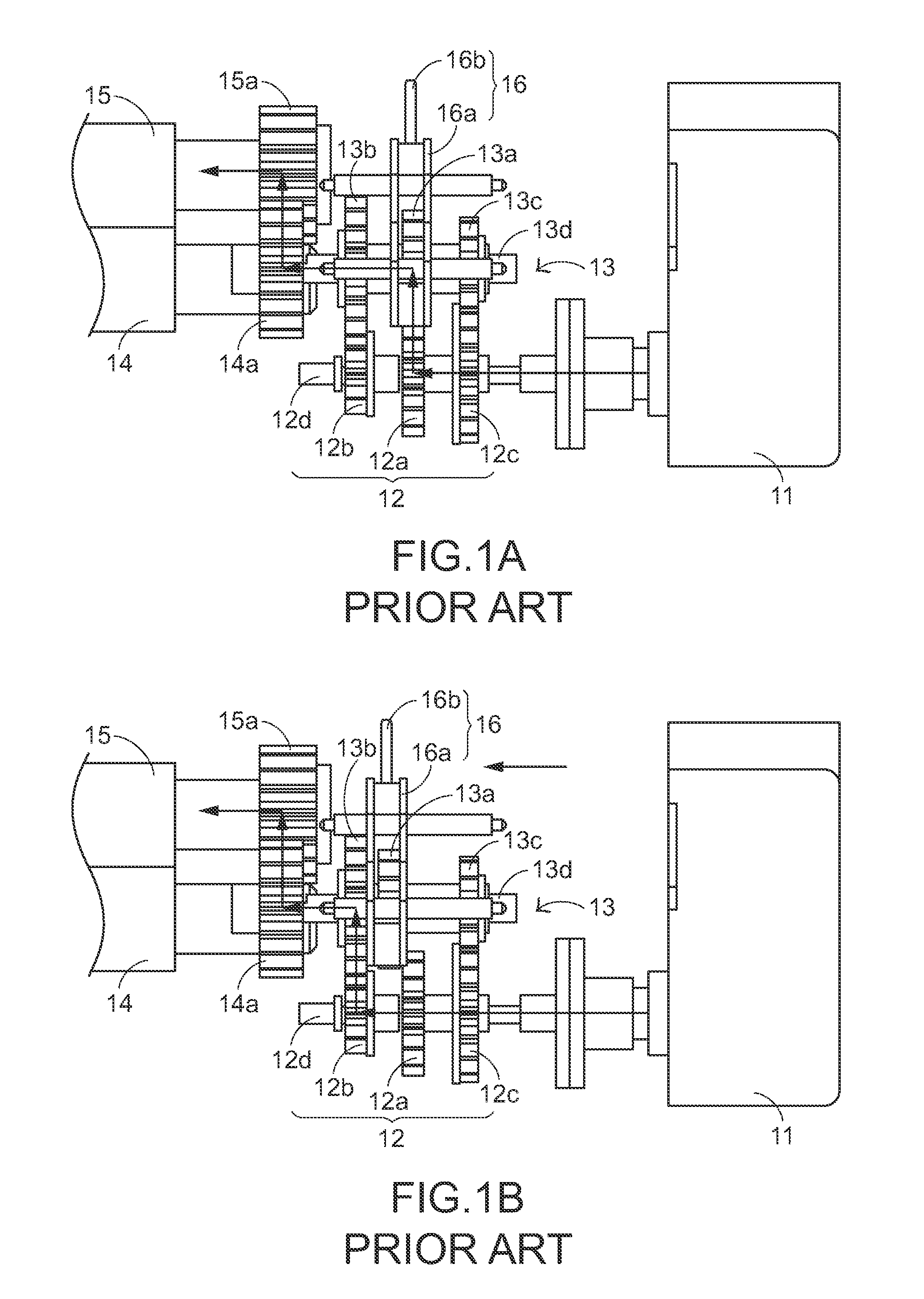

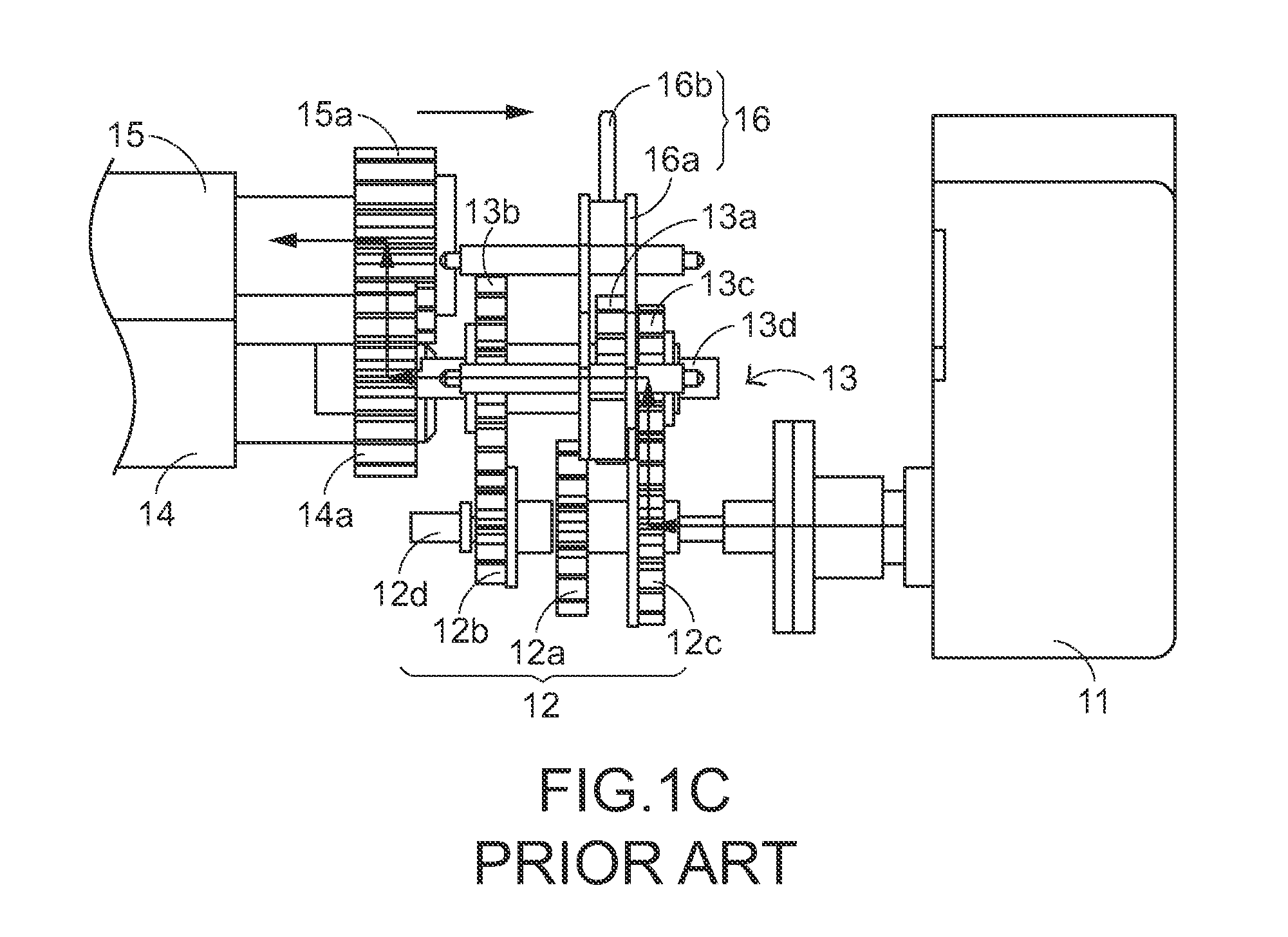

[0067]Referring to FIG. 2 to FIG. 6 together, wherein FIG. 2 illustrates a perspective view of a laminator according to a first embodiment of the present invention, FIG. 3 illustrates a perspective view of the speed changing gear set and the second driving device of the laminator according to a first embodiment of the present invention, FIG. 4 illustrates a schematic view of the gear wheel of the laminator according to a first embodiment of the present invention, wherein each of the teeth of the gear wheel has two chamfers, FIG. 5 illustrates a schematic view of the input interface of the laminator according to a first embodiment of the present invention, and FIG. 6 illustrates a block diagram of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com