Low-pressure plasma system with sequential control process

a plasma system and sequential control technology, applied in the direction of electrical equipment, basic electric elements, electric discharge tubes, etc., can solve the problems of increasing the risk that a user of the low pressure plasma system actuates the mechanical switches in the incorrect sequence, and the general use of contactors on the fully automatic controller is therefore complex and cost-intensive, so as to achieve significant safety and procedural stability of the low pressure plasma system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

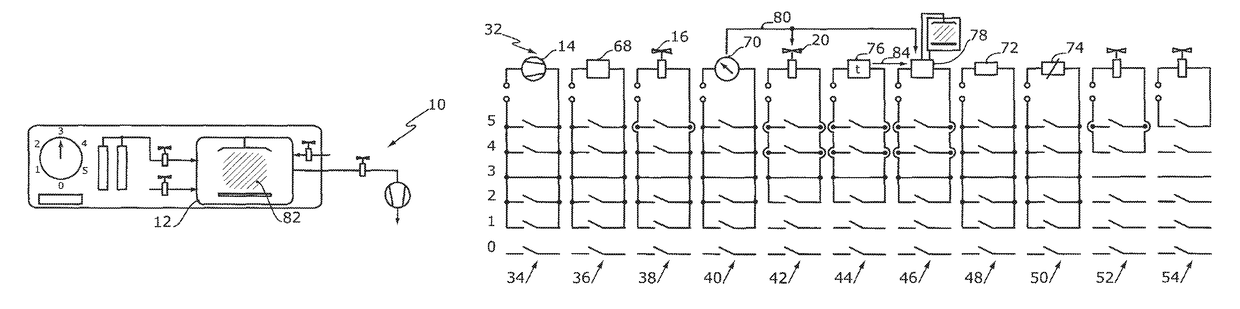

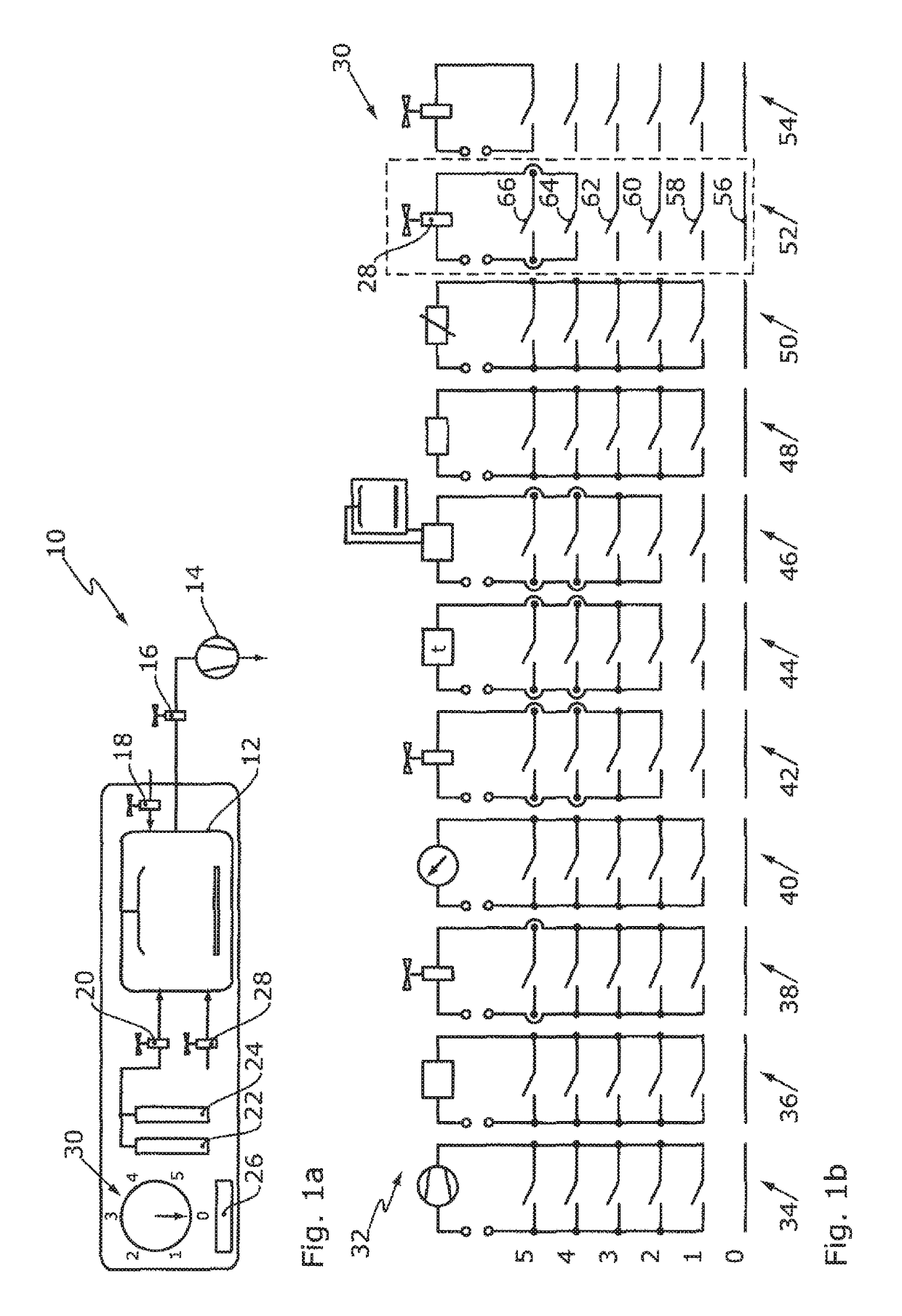

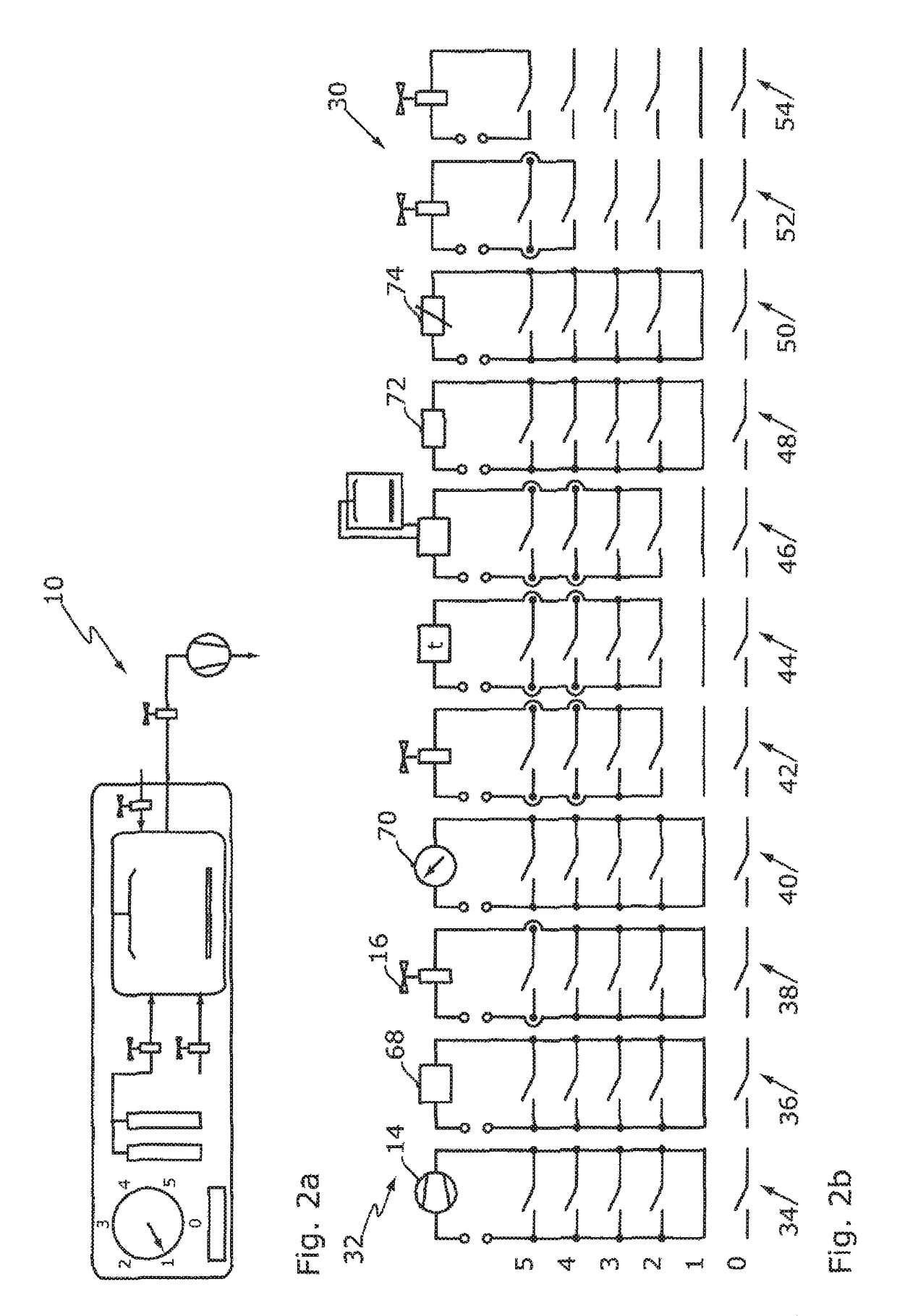

[0050]FIG. 1a illustrates a low pressure plasma system 10 in accordance with the invention. The low pressure plasma system 10 is illustrated in a heavily schematic manner. The low pressure plasma system comprises a treatment chamber 12 that can be at least in part evacuated by means of a pump 14. The pump 14 is connected in a fluid manner by way of a pump valve 16 to the treatment chamber 12. Consequently, in the case of a switched-on pump 14 and an opened pump valve 16 the treatment chamber 12 can be at least in part evacuated. The pump valve 16 is preferably embodied in the form of an angle valve.

[0051]A ventilation valve 18 is provided in order to ventilate the treatment chamber 12. A process gas can be admitted into the treatment chamber 12 by way of a gas supply valve 20. The process gas can be ambient air. As an alternative or in addition thereto, one or multiple gases can be admitted into the treatment chamber 12 as the process gas. In order to admit different gases into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com