Incandescent lamp

a technology of incandescent lamps and incandescent lamps, which is applied in the direction of discharge tube main electrodes, transportation and packaging, lighting and heating apparatus, etc., can solve the problems of vibration and impact on the motor, and achieve the effects of improving the adhesion to the bridge, improving the vibration resistance and impact resistance of the incandescent lamp, and improving the degree of coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

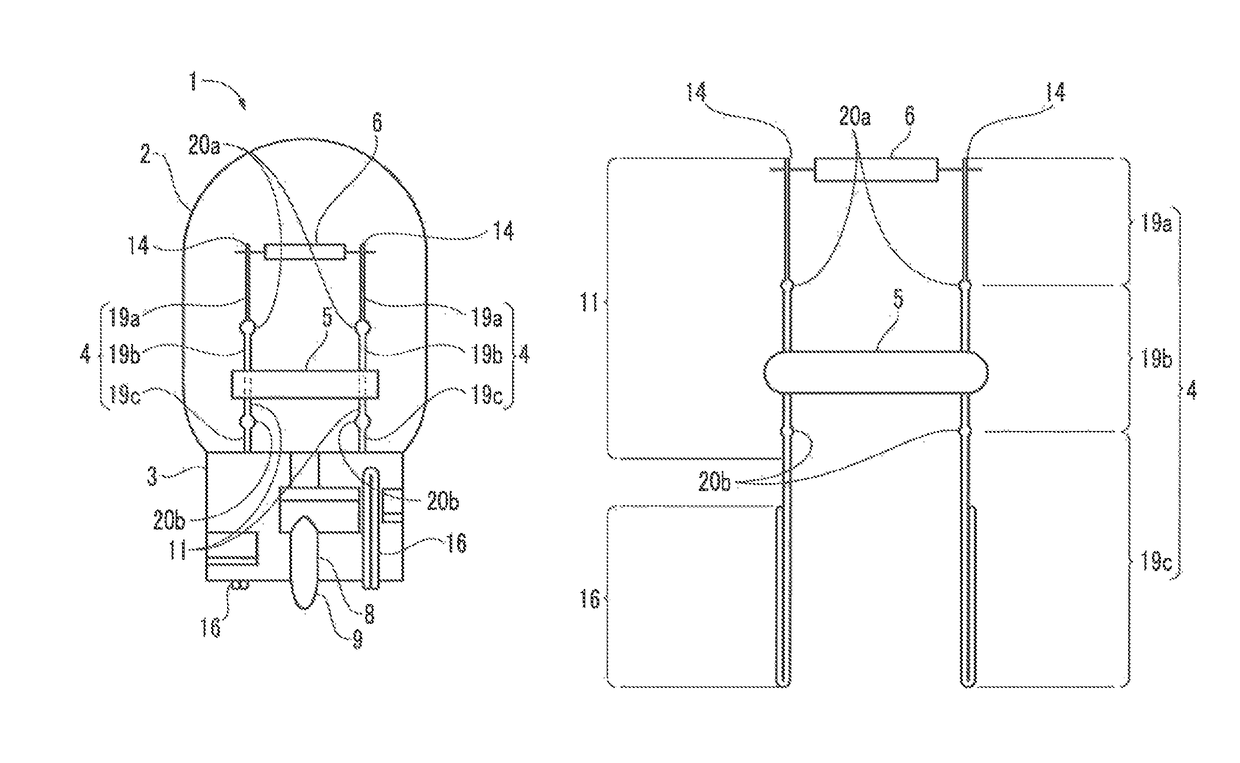

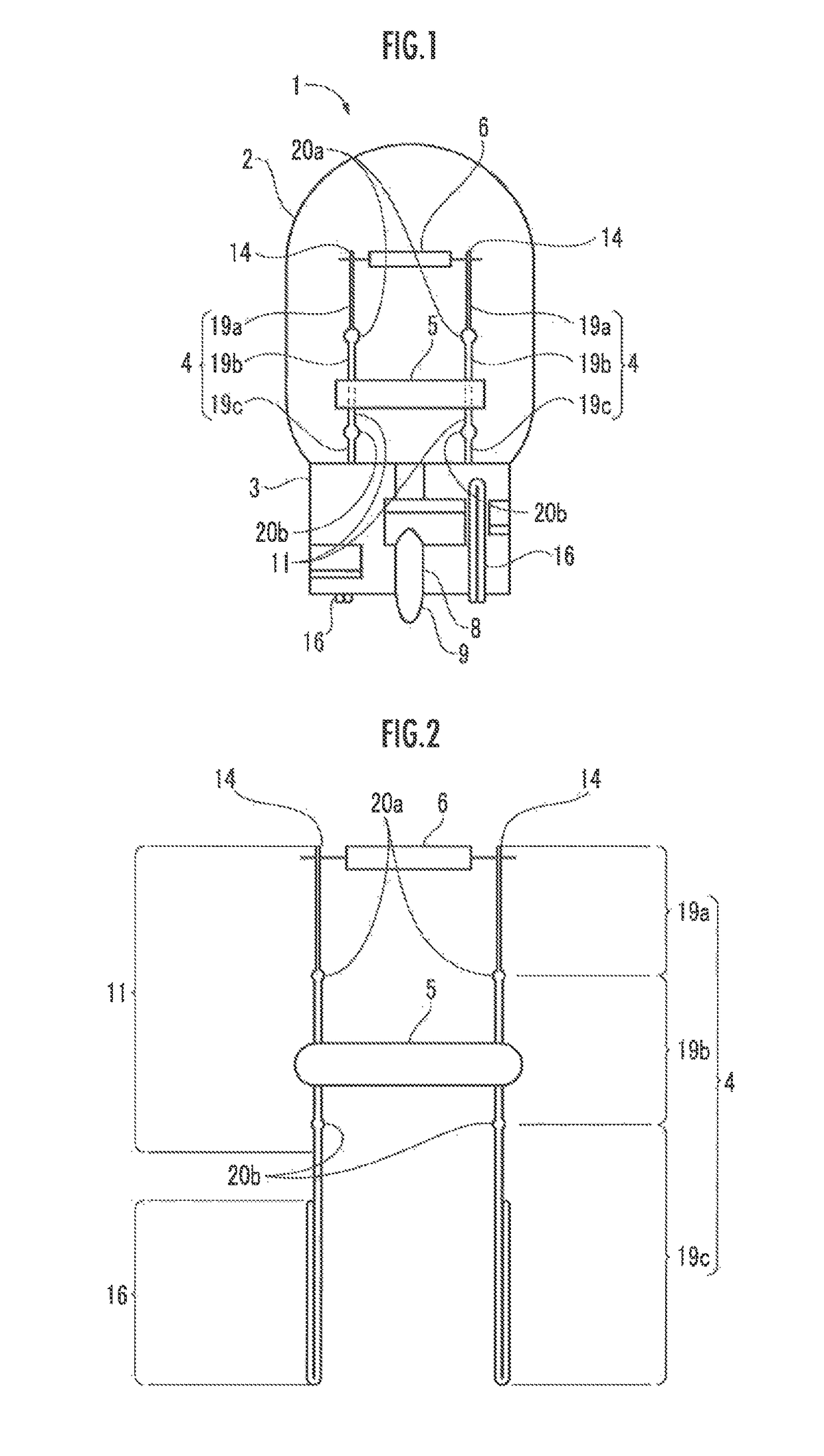

[0022]FIG. 1 is a side view of an incandescent lamp 1. The incandescent lamp 1 is provided as, for example, an automobile headlight at the front of the automobile.

[0023]The incandescent lamp 1 includes a bulb 2, a pinch seal part 3, a pair of lead wires 4, a bridge 5, a filament 6, and an exhaust pipe 8. The bulb 2, the pinch seal part 3, the bridge 5, and the exhaust pipe 8 are formed of soft glass for the purpose of melting point reduction. In the present embodiment, the same glass material is used as the soft glass of the bulb 2, the pinch seal part 3, the bridge 5, and the exhaust pipe 8, which are all colorless and transparent. However, it is possible to appropriately adopt, for example, umber other than a solid color as a color of the bulb 2.

[0024]The exhaust pipe 8 is arranged on a side surface of the pinch seal part 3. While not yet subjected to pinch sealing processing in production processes of the incandescent lamp 1, the pinch seal part 3 is formed into a cylindrical sha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap