Display apparatus

a technology of display apparatus and display plate, which is applied in the field of display plate, can solve the problems of affecting the appearance of the display plate, so as to prevent the damage prevent the fluctuation of the optical plate, and reduce the effect of luminan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

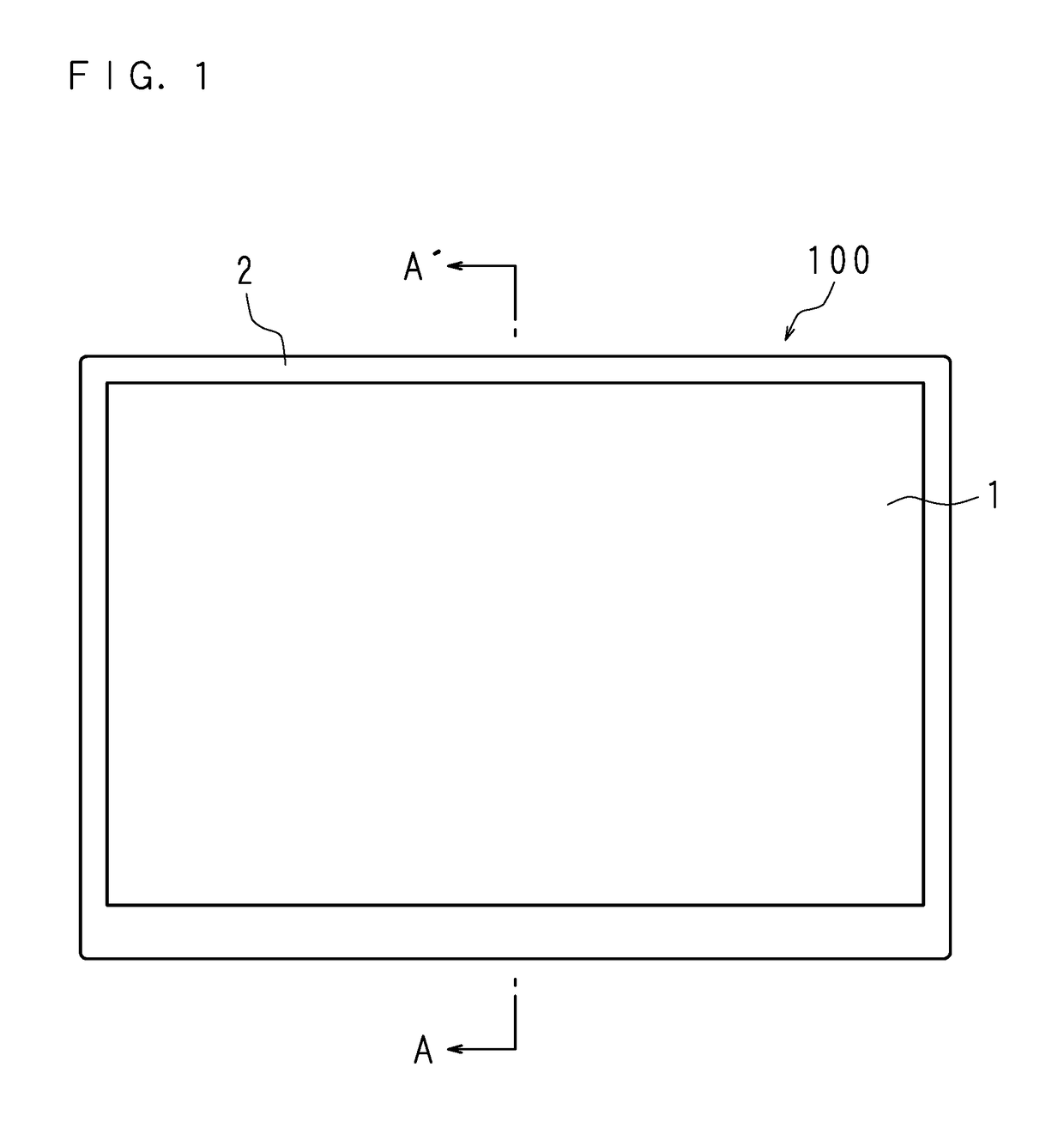

[0028]FIG. 1 is a front view illustrating an appearance of a display apparatus 100 according to Embodiment 1. The display apparatus 100 is formed by positioning and housing a liquid crystal panel 1 and other parts by a plurality of other chassis including a first chassis 2.

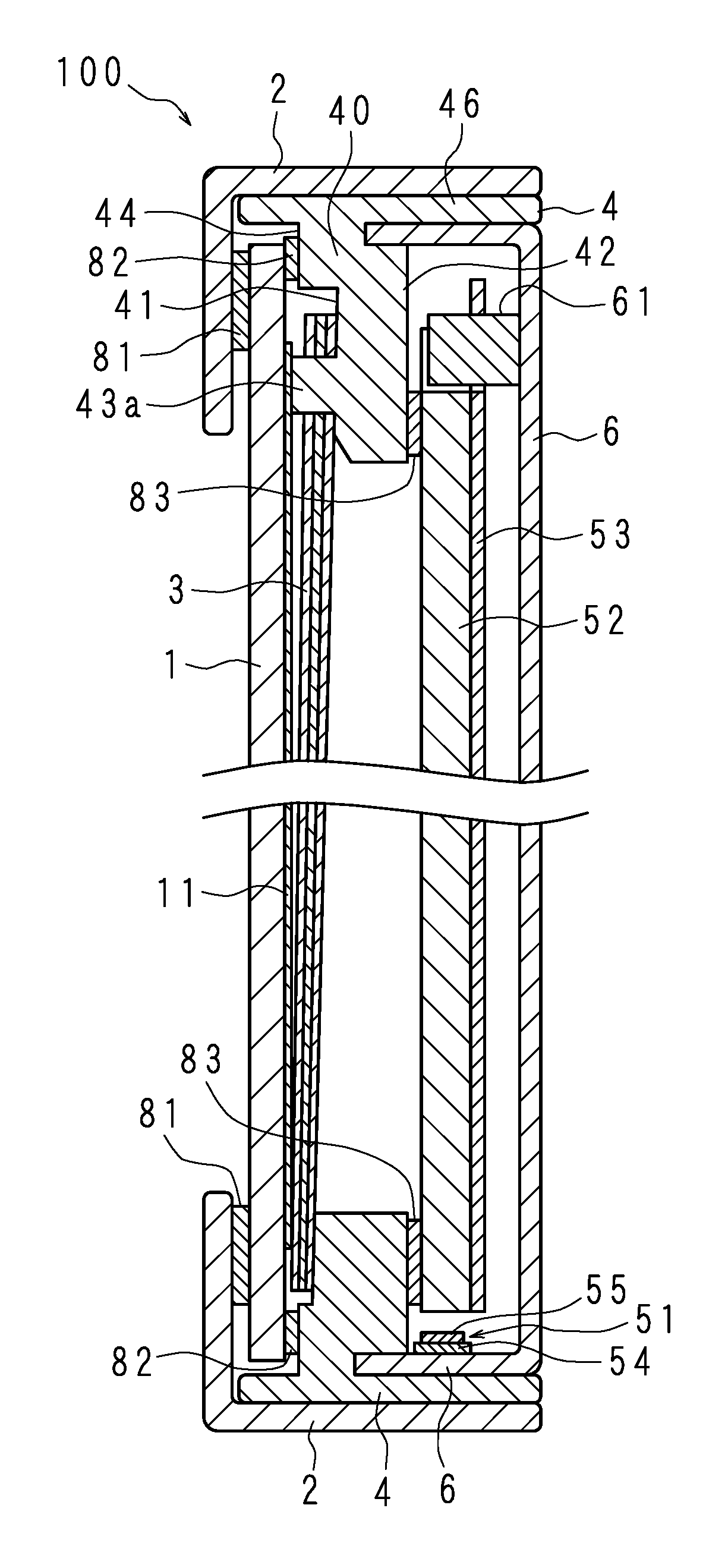

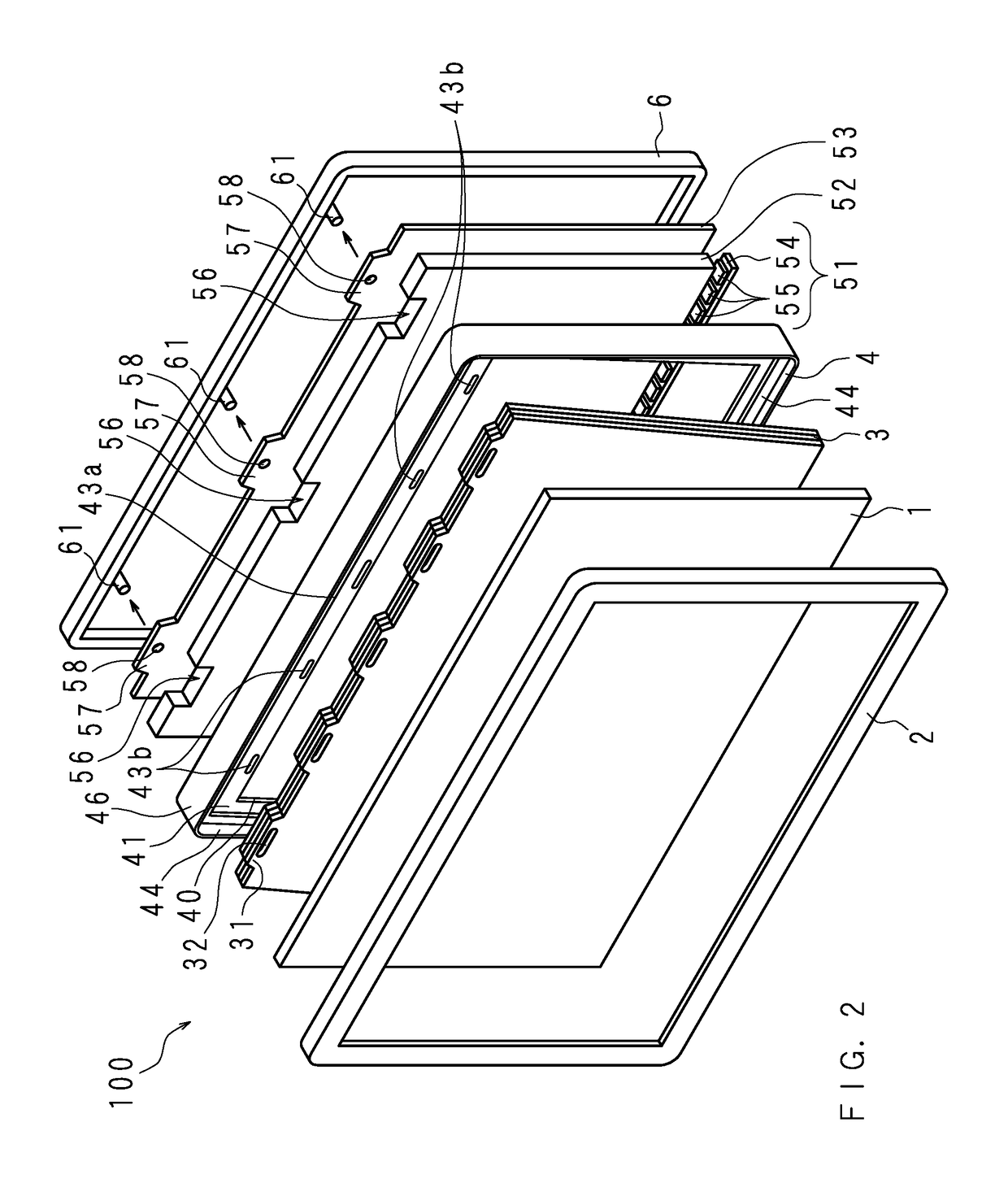

[0029]FIG. 2 is an exploded perspective view schematically illustrating main components included in the display apparatus 100 according to Embodiment 1, and FIG. 3 is a longitudinal-sectional view taken on line A-A′ of FIG. 1.

[0030]The display apparatus 100 includes the liquid crystal panel 1, the first chassis 2, an optical sheet 3, a second chassis 4, a light guide plate 52, a light source 51, a reflection sheet 53, and a third chassis 6.

[0031]The first chassis 2 is a rectangular-shaped frame body. The first chassis 2 includes a side plate of a rectangular and cylindrical shape, and a frame part of a hollow plate protruding inward from one end portion of the side plate, and has an L-shaped cross section.

[0032]Th...

embodiment 2

[0060]The structure of the second chassis 4 to prevent the optical sheet 3 from being fluctuated may be a structure as Embodiment 2 illustrated below. FIG. 5 is a perspective view schematically illustrating a second chassis 7 according to Embodiment 2, and FIG. 6 is a longitudinal-sectional view taken on line C-C′ of FIG. 5. FIG. 6 illustrates a cross section when cutting an edge part of a holding plate 70 of the second chassis 7 on one short side in the lateral direction. Further, a dashed line in FIG. 6 illustrates an outline of the cross section of the optical sheet 3 to be held.

[0061]The second chassis 7 may be used as a substitute for the second chassis 4 according to Embodiment 1 as it is. Therefore, the configuration of other main components of the display apparatus 100, and the relationship with the other main components of the second chassis 7 will not be described in detail.

[0062]The second chassis 7 is a frame body provided with a peripheral plate 76 at outer peripheral e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shape | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com