Maximise the value of a sulphide ore resource through sequential waste rejection

a technology of sulphide ore and waste, applied in the direction of process efficiency improvement, flotation, grain treatment, etc., can solve the problems of large energy and water consumption, high capital and operating costs, high cost of fine grinding, etc., and achieve the effect of maximising the removal of gangu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

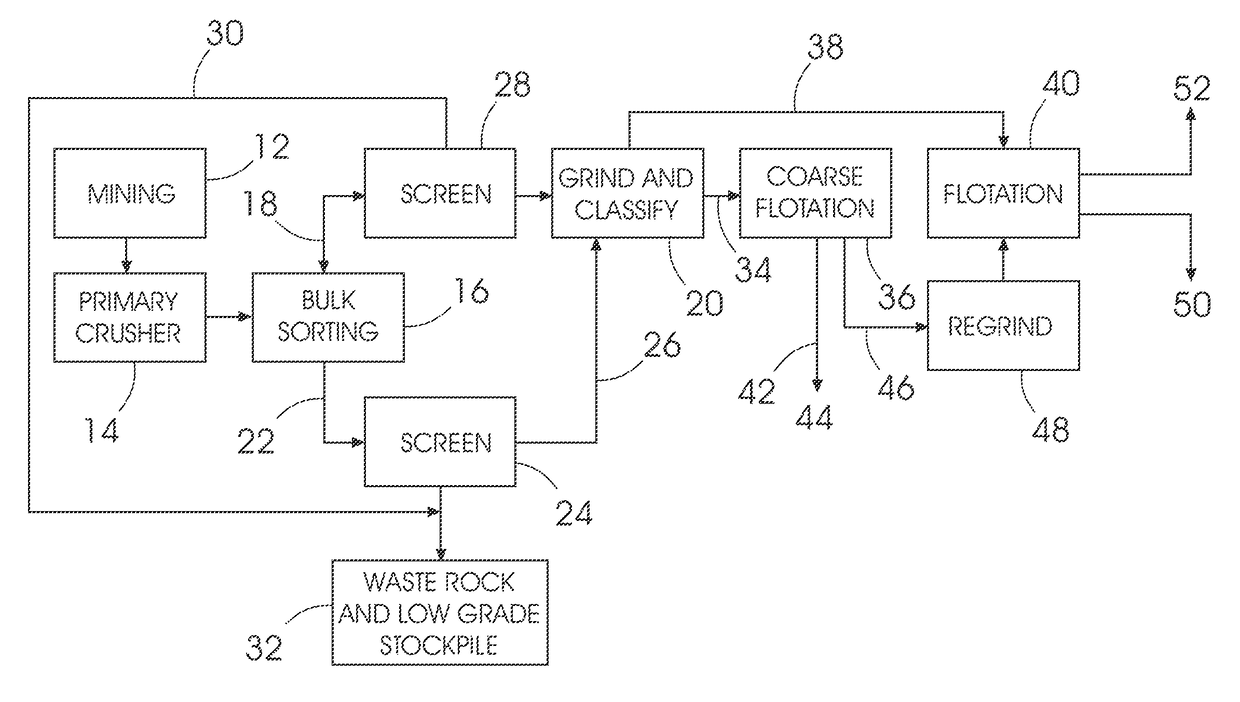

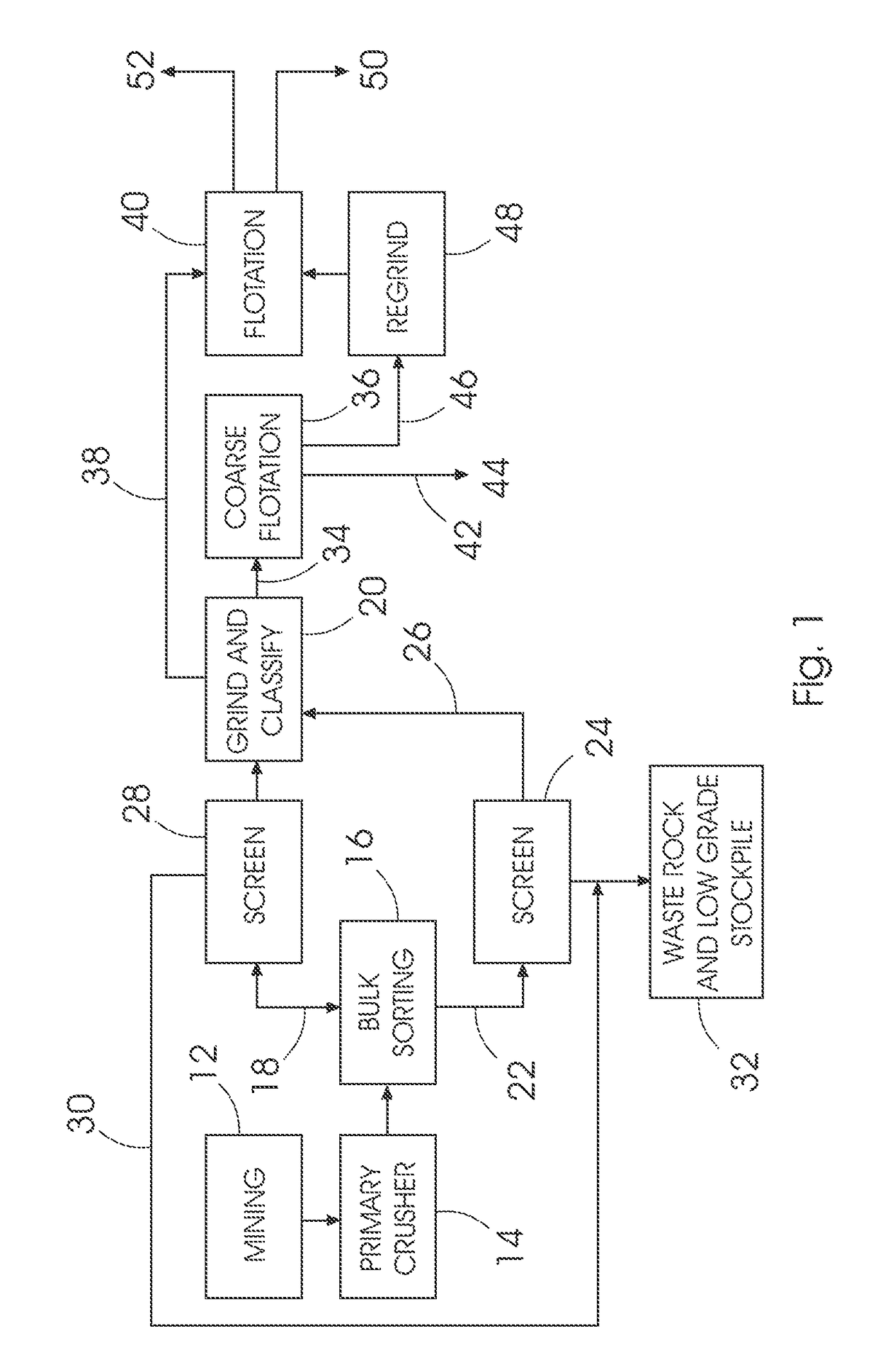

[0062]The present invention relates to a process that capitalises on the natural heterogeneity of sulphide orebodies, and utilises beneficiation technologies in a novel multistage configuration to reject the maximum quantity of waste gangue prior to fine comminution. This rejected gangue is normally below economic reprocessing grade (i.e. waste) but might also be in the form of a feed to heap leach; or in the form of a low grade stockpile for treatment later in the mine life (grade profiling).

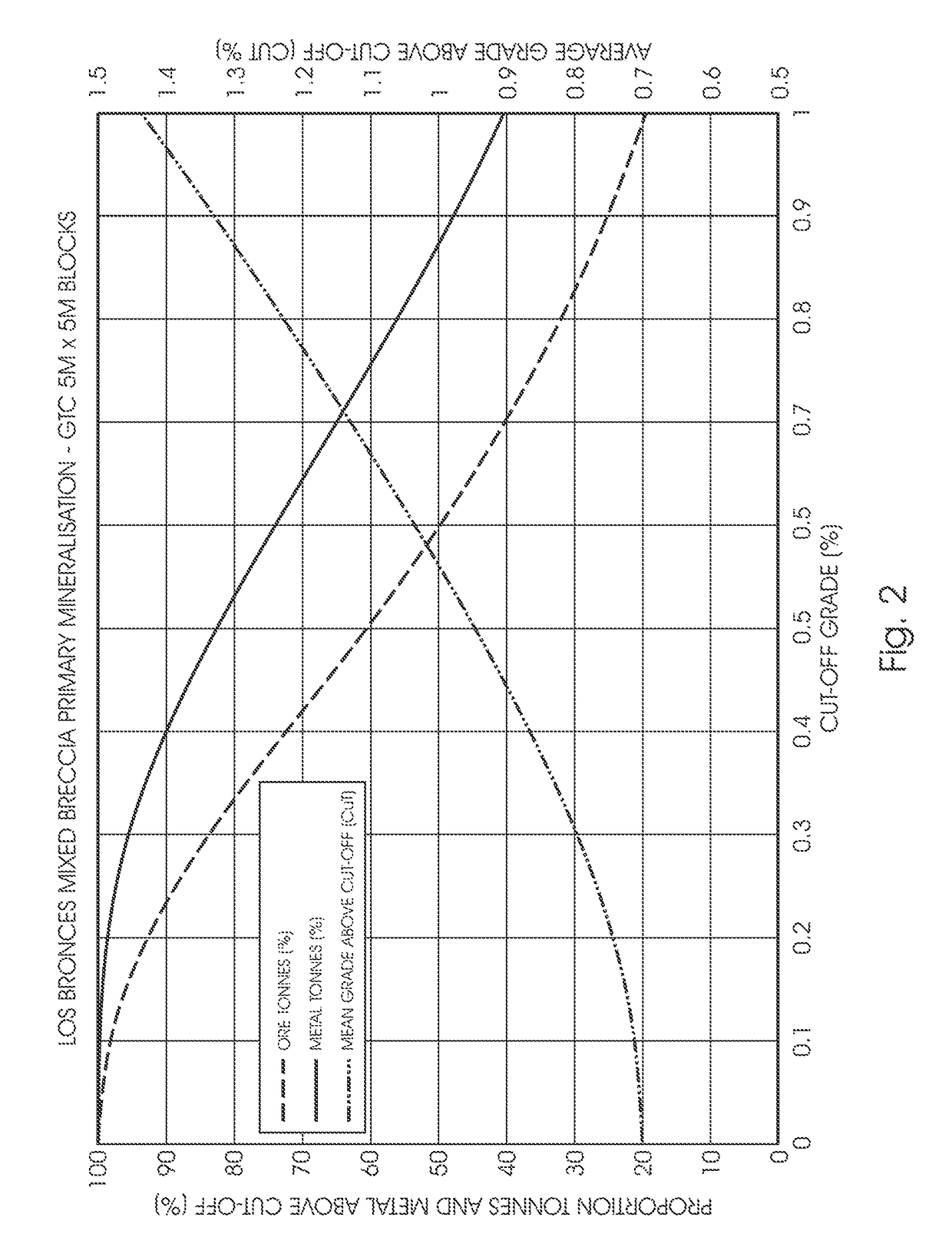

[0063]The exact quantum of benefits will be dependent on the grade recovery characteristics of a particular orebody. However, using combination of the techniques, the water and comminution energy consumption are typically reduced by 50-80% at the same mining cut-off-grade (CoG). Alternatively, the mining cut-off-grade can be reduced, extending the life of mine, and achieve only slightly lower reductions in overall water and energy consumption. The invention also enables unit costs of production...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com