Method and apparatus for driving display panel

a display panel and display panel technology, applied in the direction of instruments, static indicating devices, etc., can solve the problems of phosphor being relatively fragile against a hitting of ions, not accumulating sufficient wall charges, self-erase discharge, etc., and achieve excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

eighth embodiments

First to eighth embodiments of the present invention will be explained with reference to FIGS. 18 to 51.

first embodiment

of FIG. 18

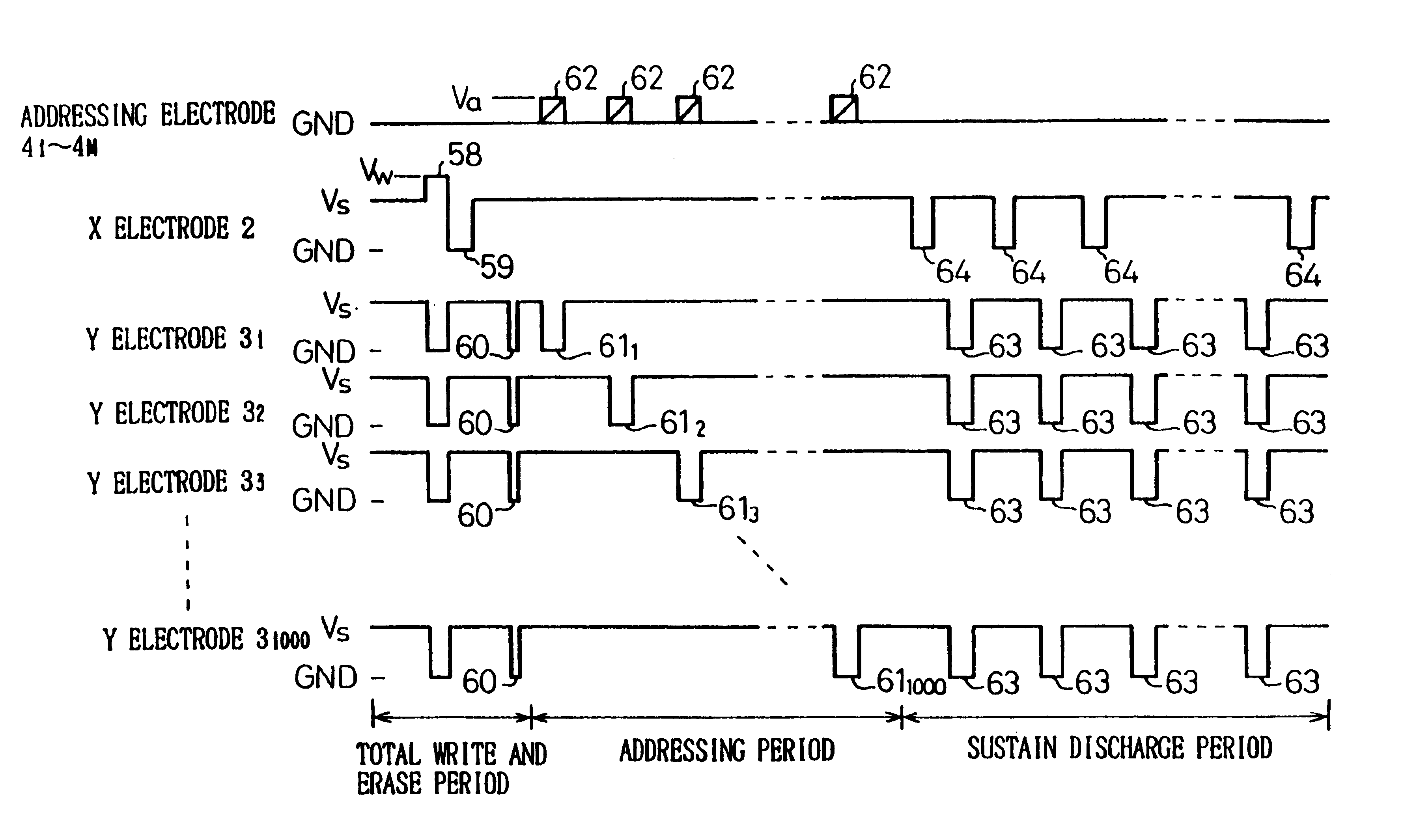

FIG. 18 is a waveform diagram showing the first embodiment of the present invention. The figure shows one drive cycle. This embodiment drives the PDP of FIG. 1 according to the sequential line driving method.

According to this embodiment, the potential of the Y electrode of a selected line is set to GND, the potential of the Y electrodes of unselected lines is set to Vs, and a write pulse 36 having a voltage of Vw is applied to the X electrode 2, to discharge all cells of the selected line.

Thereafter, the potential of the Y electrode of the selected line is returned to Vs, and a sustain discharge pulse 37 is applied to the X electrode 2, to carry out sustain discharge. A narrow erase pulse 38 is applied to the Y electrode of the selected line, to carry out erase discharge in all cells of the selected line.

An addressing pulse (a write pulse) 39 having a potential level of GND is applied to the Y electrode of the selected line. The Y electrodes of the unselected lines are kep...

second embodiment

The second embodiment applies a wide erase pulse 44 to the Y electrode of a selected line. The rest of this embodiment is the same as the first embodiment.

The second embodiment equalizes all cells of a selected line before writing display data thereto. Similar to the first embodiment, the sequential line driving method according to the second embodiment prevents a write error and displays a quality image.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com