Angle measuring system with a clampable shaft

a technology of clamping shaft and measuring system, which is applied in the direction of couplings, instruments, mechanical equipment, etc., can solve the problems of axial displacement, radial spreading of the slitted shaft end, and other elements, and achieve the effect of simple clamping, simple construction and reliable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

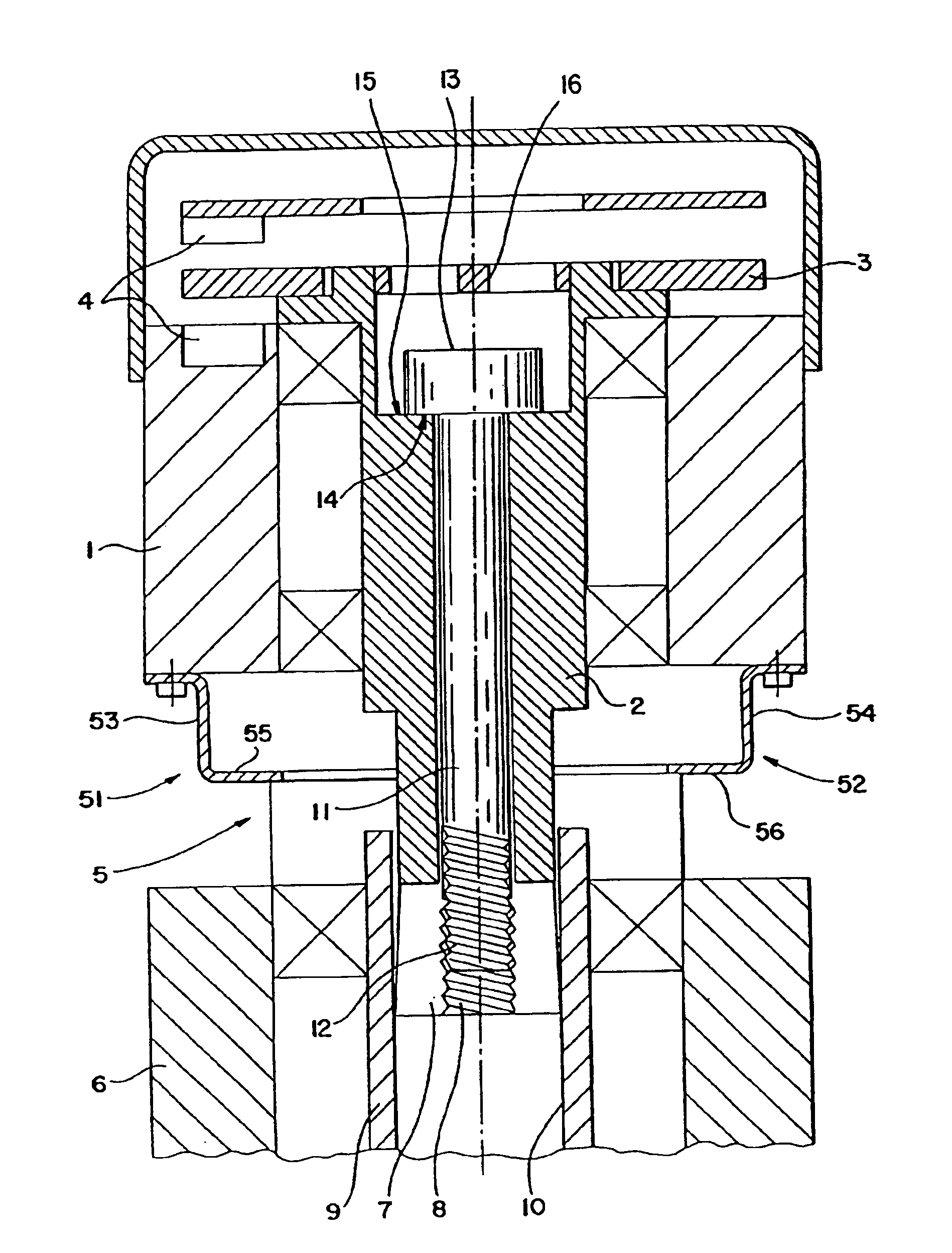

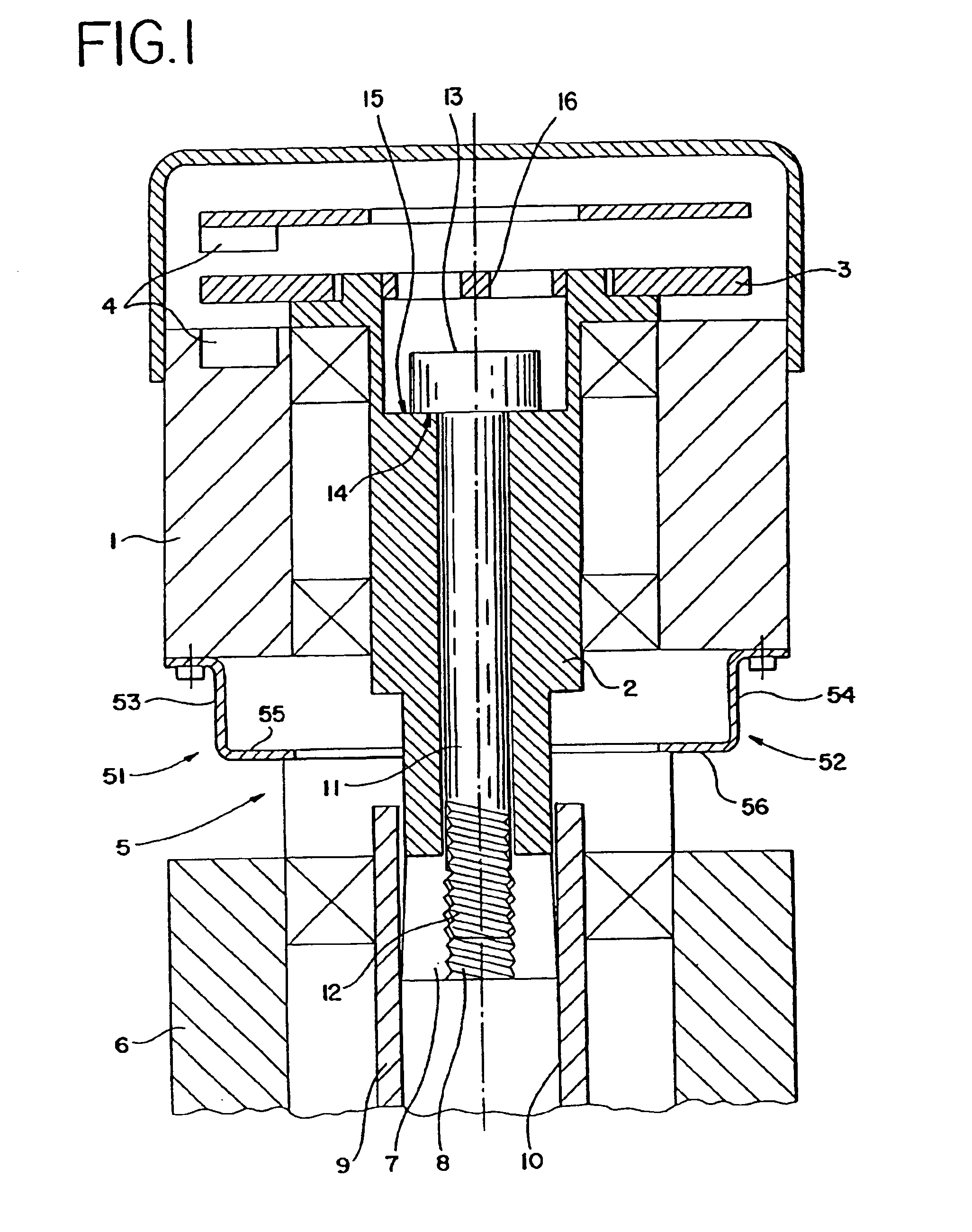

Embodiment Construction

[0012]The angle measuring system shown in FIG. 1 includes a stator 1, a pick-up shaft 2, a coding disk 3, a scanning unit 4, a coupling 5, and a stationary element 6 of a drive unit, for example, a motor. The pick-up shaft 2 is preferably continuously hollow and is rotatably seated in the stator 1. The coding disk 3 is fastened to a first end of the pick-up shaft 2 by glue, for example. In a preferred embodiment an incremental or absolute coding is placed on the coding disk 3. The coding disk 3 is scanned by the scanning unit 4 which emits position-dependent electrical signals as is well known to those of ordinary skill in the art and thus need not be described in detail herein.

[0013]The stator 1 is fastened by coupling 5 to the stationary element 6. The coupling 5 assures a connection, fixed against relative rotation, of the stator 1 and the stationary element 6, but permits compensating movements between these two elements in all directions. The coupling 5 is especially rigid and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com