Magnetic head suspension assembly fabricated with integral load beam and flexure

a technology of load beam and flexure, applied in the direction of magnetic recording, instruments, data recording, etc., can solve the problems of weak pitch, roll and bending stiffness, and achieve the effect of reducing z-heigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

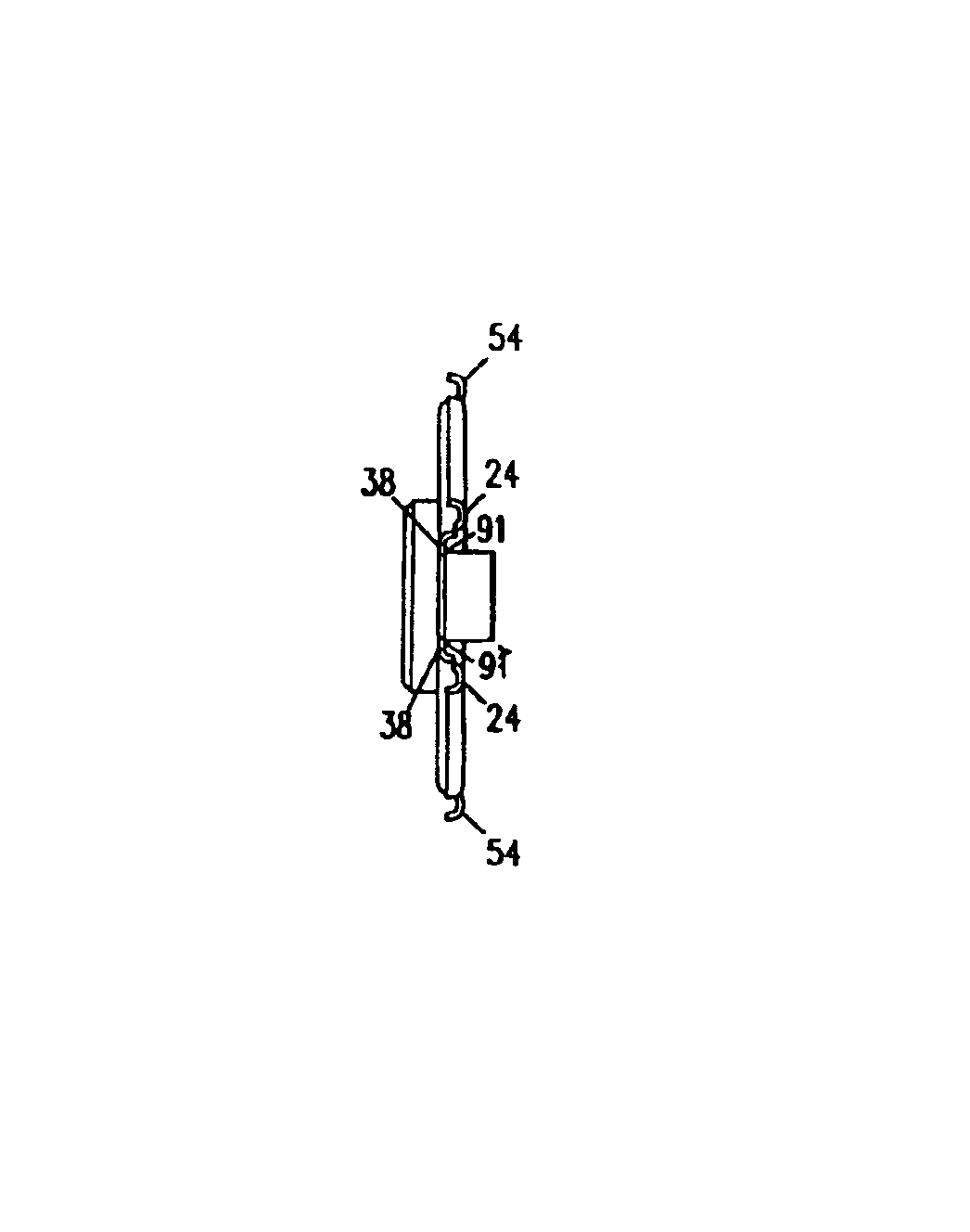

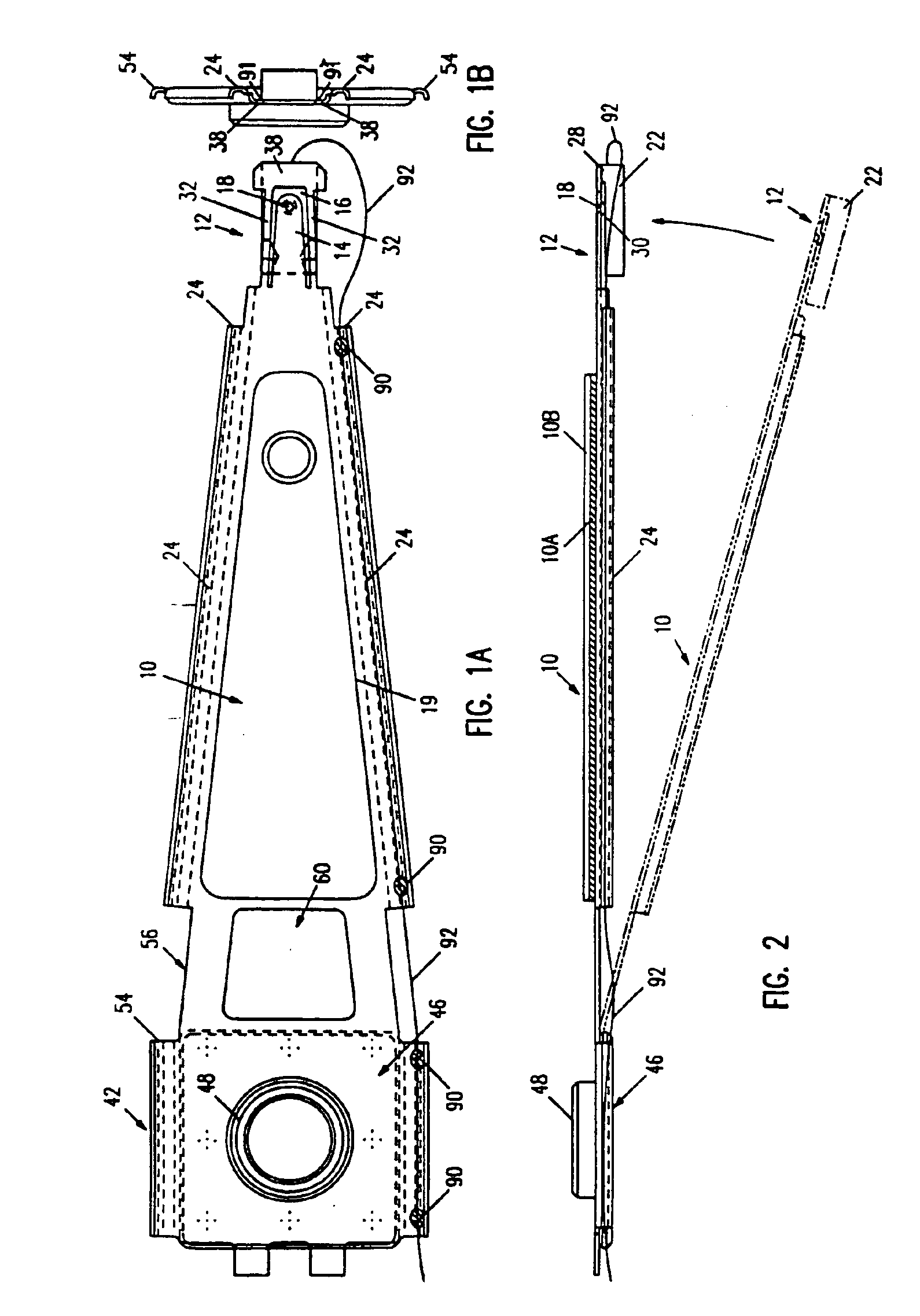

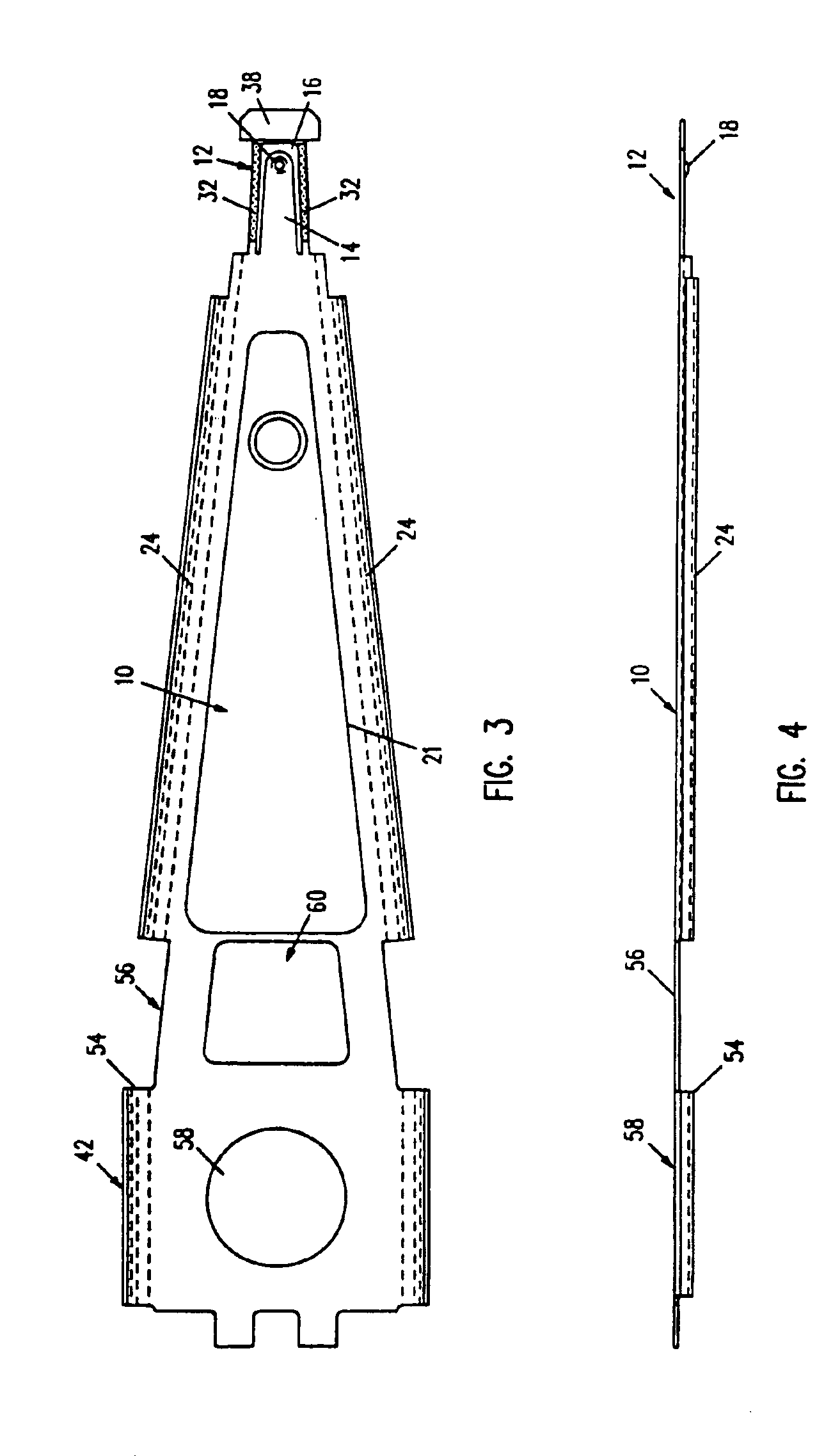

[0037]With reference to FIGS. 1A-5B, a magnetic head suspension assembly includes a load beam section 10, a flexure section 12, a leaf spring section 56 and a rear mount section 42. The suspension is formed from an integral flat piece of nonmagnetic material, preferably a 300 Series type stainless steel having a thickness of about 0.0012 to 0.0013 inch. As a result of using an integral piece, the load beam section 10 and flexure section 12, as well as the leaf spring section 56 and rear mount section 42, are disposed substantially in a single plane. No separate forming of individual load beam and flexure parts is required. Therefore, no assembly steps of joining and welding are needed for attaching the flexure to the load beam.

[0038]The load beam section 10 is preferably made in a truncated conical or triangular shape. The load beam section has a short tapered tongue 14 extending from its relatively narrow end into the flexure section 12. The tongue 14 is delineated by a U-shaped cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com