Nozzle arrangement for a paint spray gun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

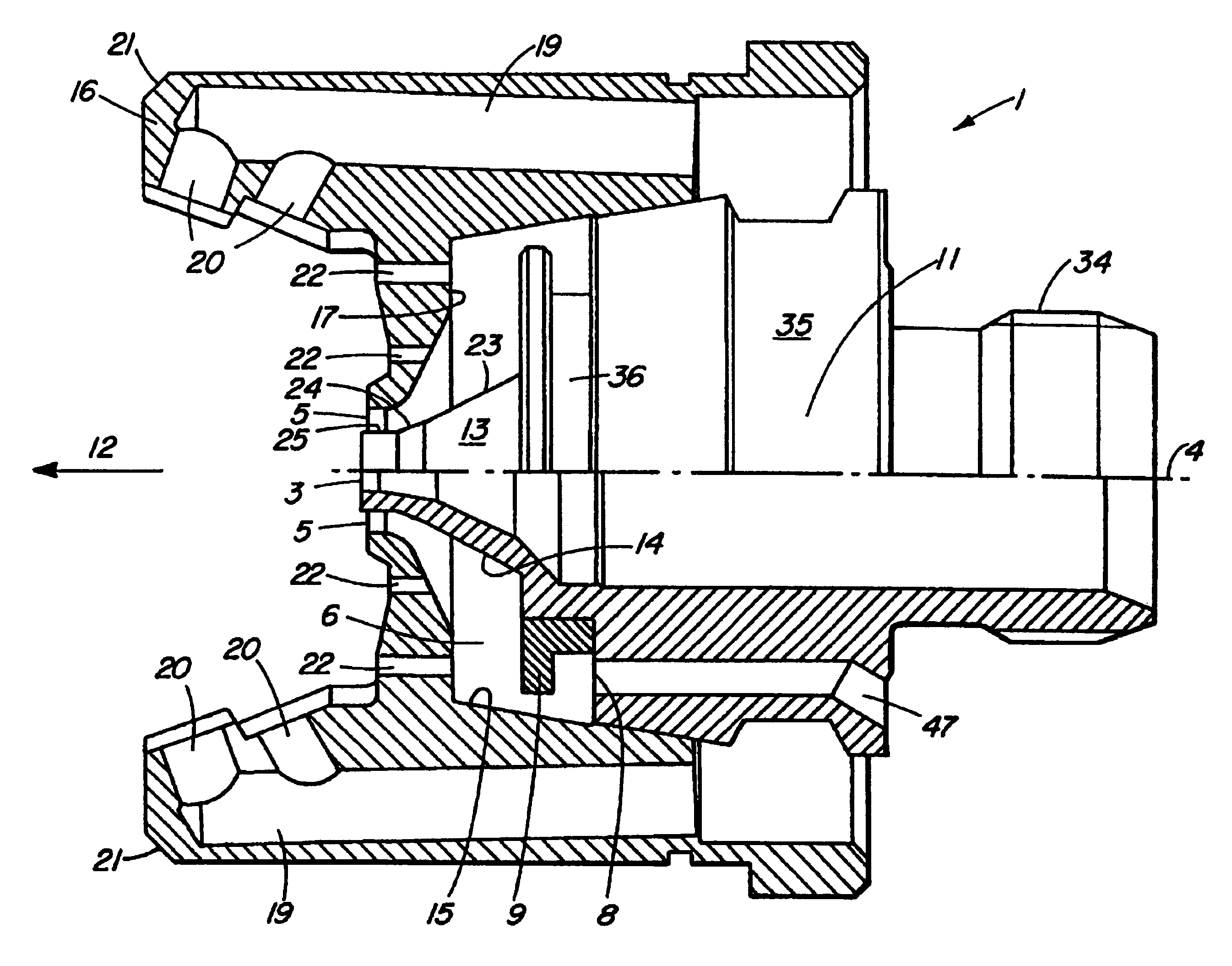

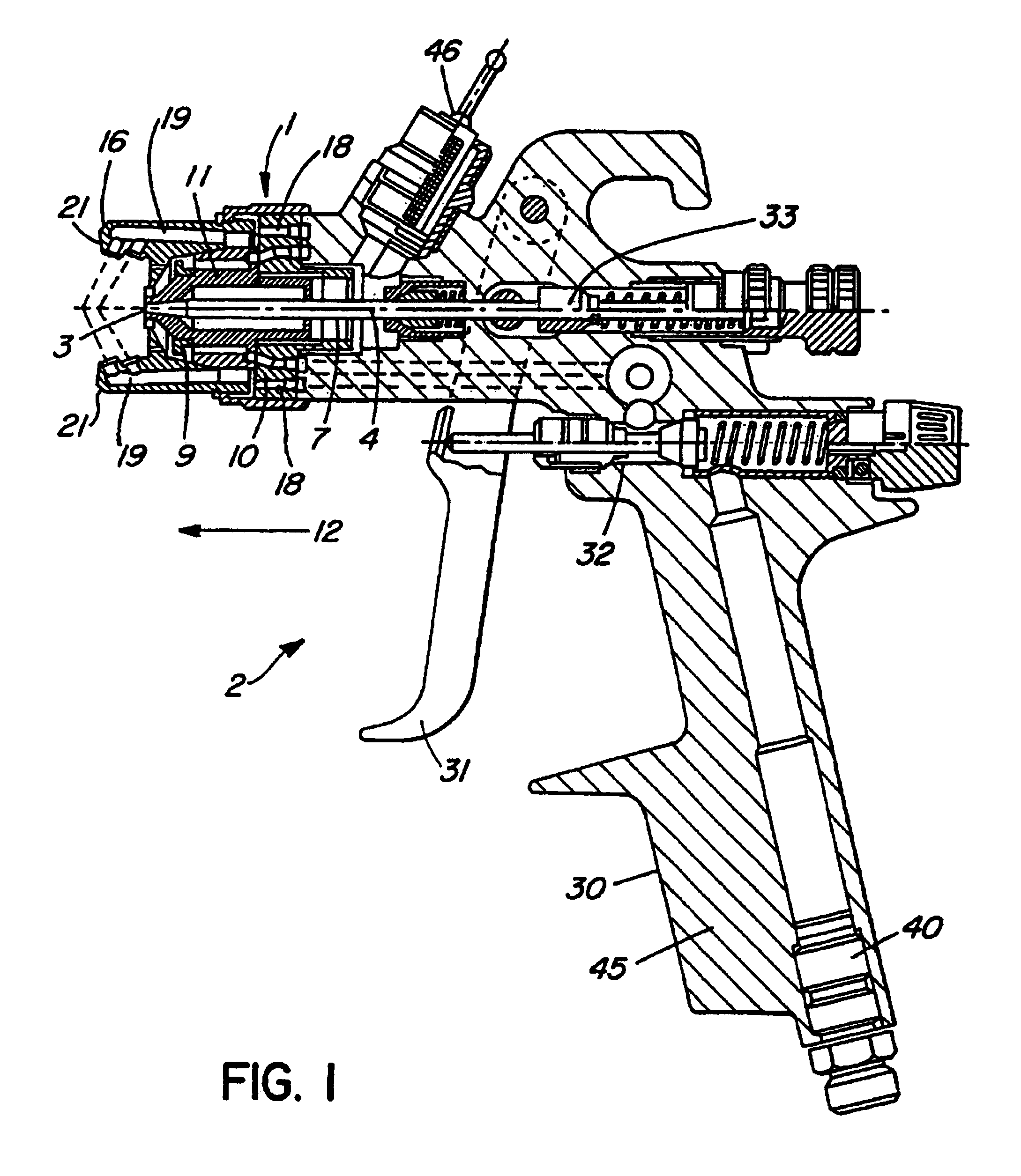

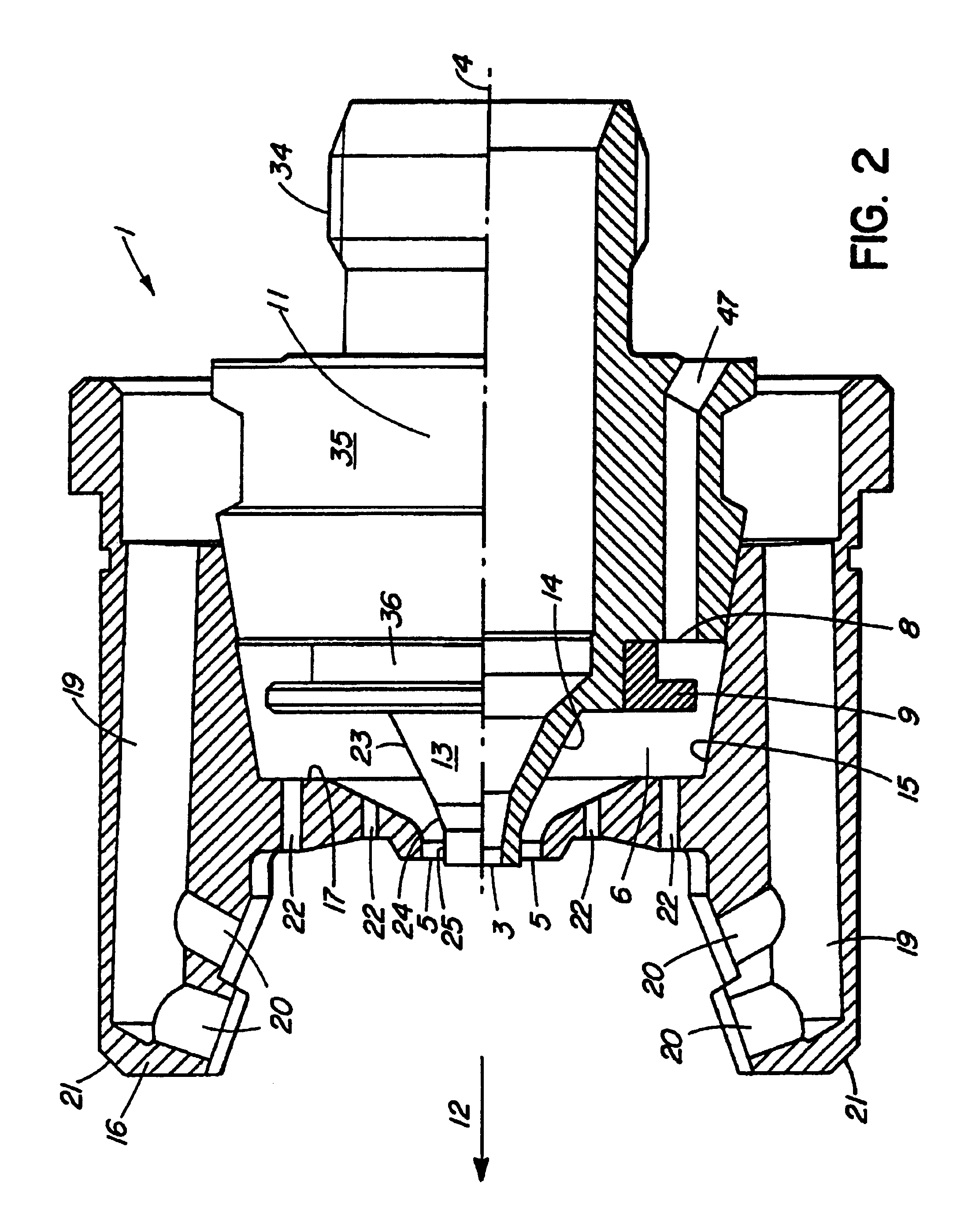

[0012]The paint spray gun shown in the Figure is comprised essentially of a housing 30 which includes an upper part with a suspension hook and a handle 45. A compressed-air supply conduit is attached to the underside of the handle 45, an air choke 40 can be built in to decrease the pressure when the air enters, primarily in low-pressure guns; a fluid container for the paint is mounted on the top at a connection 46. The compressed air (via a valve arrangement 32) and the outlet 3 (via a pin control device 33) are simultaneously released for the paint by means of an operating lever 31. The paint flows from the fluid container (not shown), without pressure support, to the outlet 3 and passes out there when the pin 7 is pulled back. Compressed air flows simultaneously via a conduit system to the annular slot 5 which surrounds the outlet 3 and produces a vacuum directly at the outlet 3. This vacuum sucks paint out of the outlet 3, which is then atomized and carried along due to the quick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com