Machine tool center

a machine tool and center technology, applied in the field of machine tool centers, can solve the problems of endangering the operator, the other machine tools in the machine tool center cannot be served by the loading device, etc., and achieve the effect of improving the functional reliability of the machine tool and increasing the work safety of the operator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

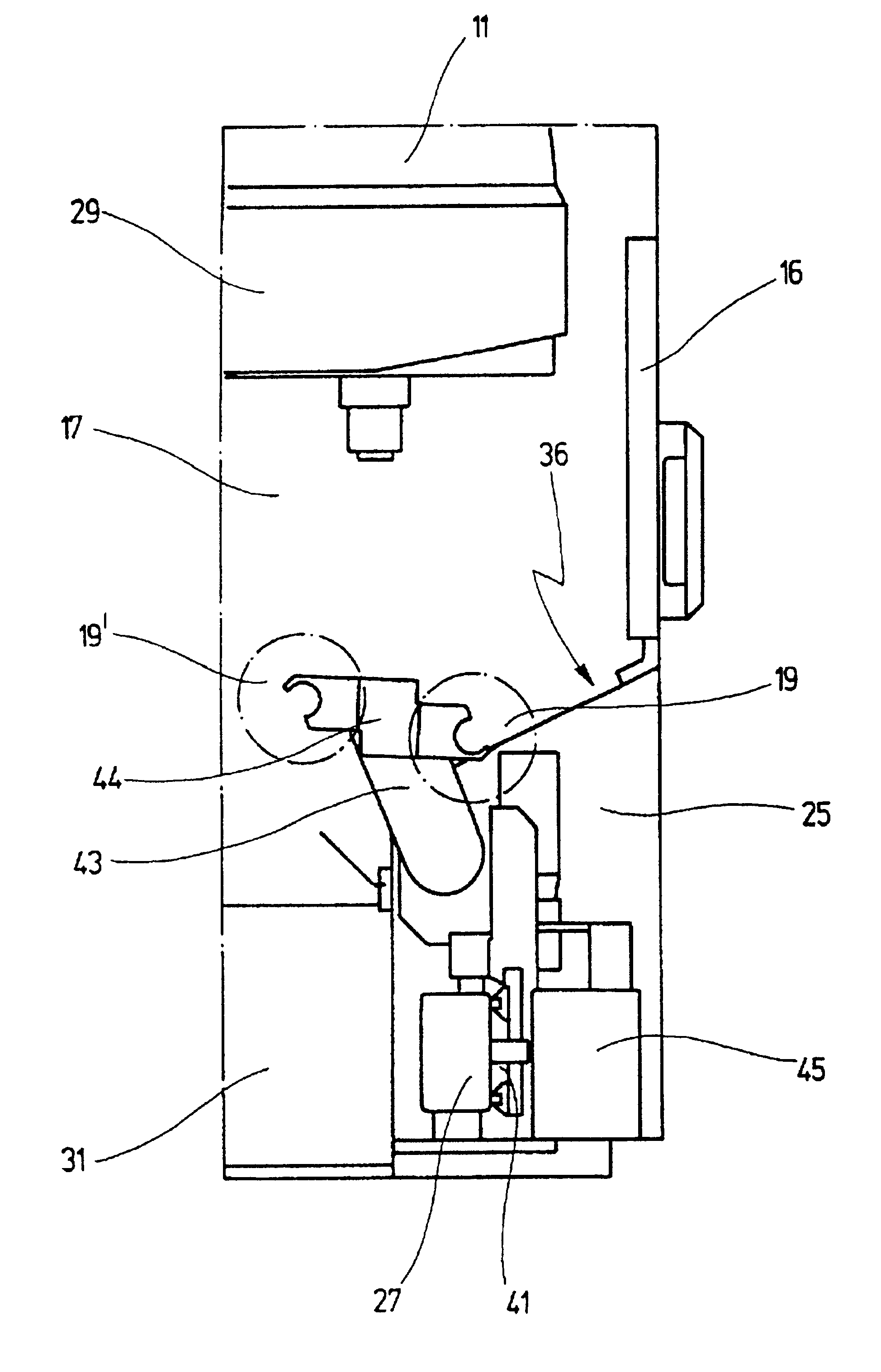

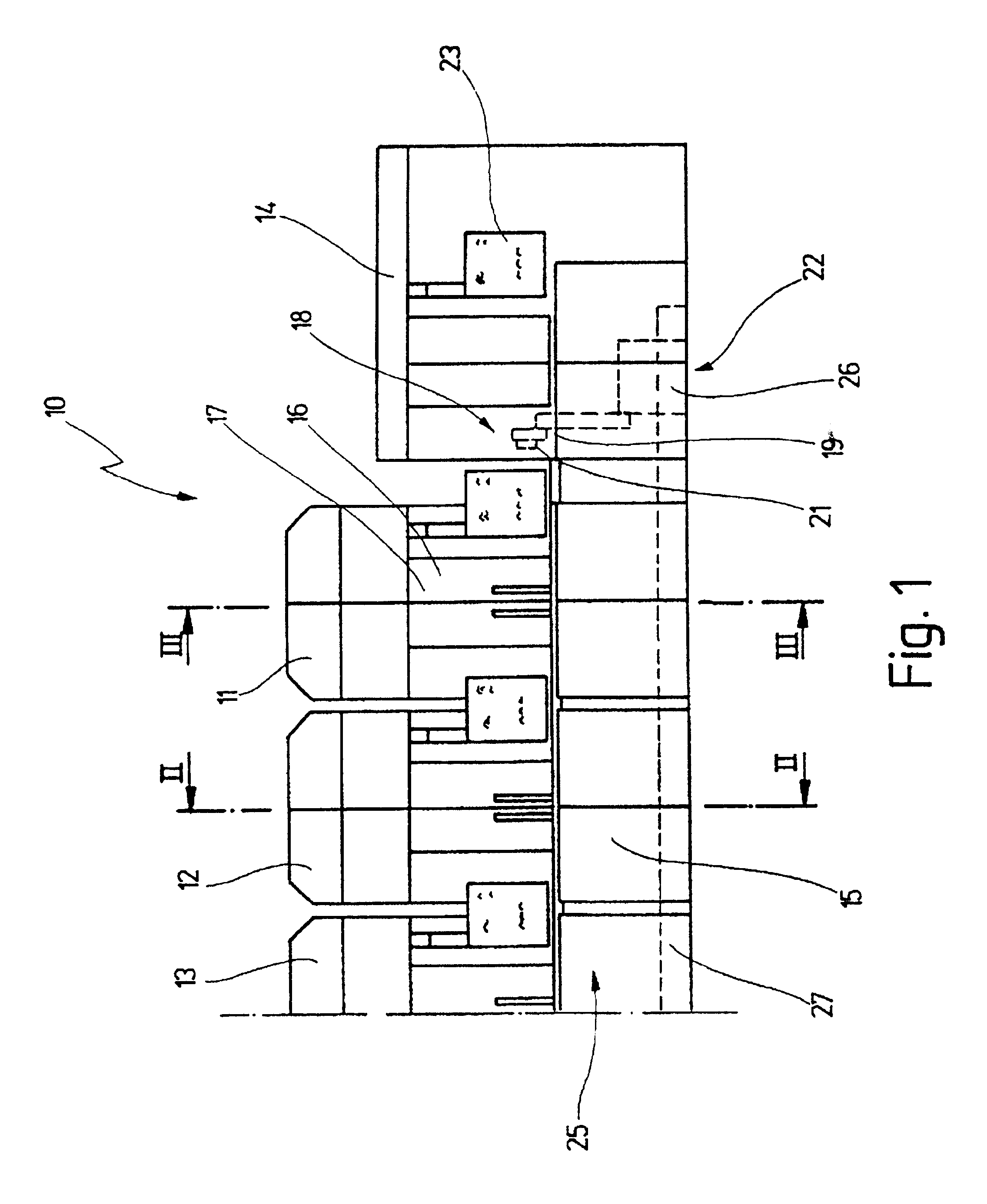

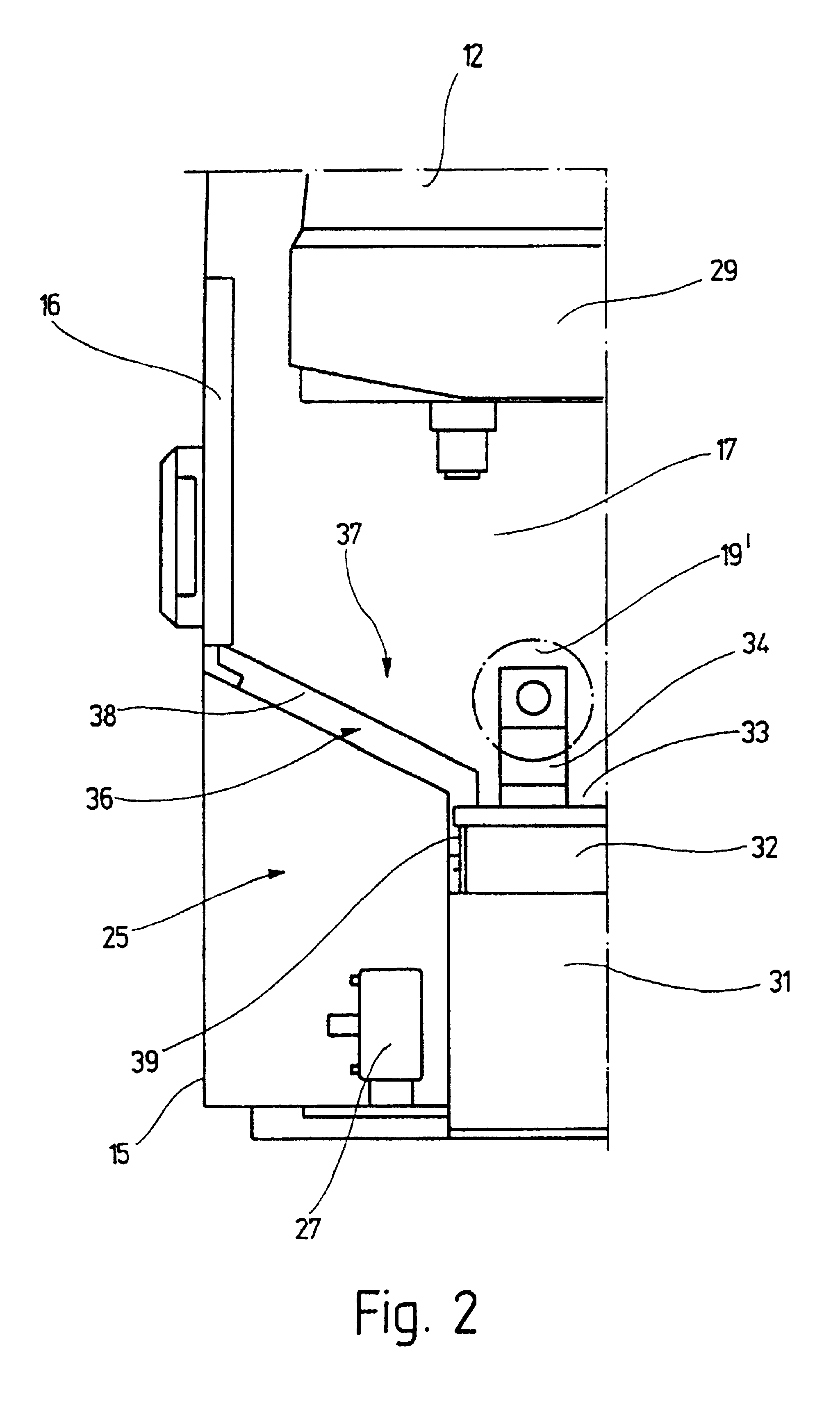

[0045]FIG. 1 shows the front view of a machine tool center 10 in which the machine tools 11, 12 and 13 (only indicated) are arranged alongside one another. These machine tools 11, 12, 13 can either be arranged in a straight line or circle. A loading / unloading station 14 is provided in addition to the machine tools 11, 12, 13.

[0046]The machine tools 11, 12, 13 display a casing 15 which completely surrounds them and in which there is an operator door 16 for each machine tool 11, 12, 13 through which an operator has access to the working space 17. Set-up and service work is carried out for the individual machine tools 11, 12, 13 through this operator door 16.

[0047]A clamping station 18, shown only diagrammatically, is provided in the loading / unloading station 14 in which individual workpiece holders 19 are provided with workpieces 21 to be processed. The workpiece holders 19 provided with workpieces 21 in this manner are transported to the individual machine tools 11, 12, 13 by means o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com