Temperature compensated high power bandpass filter

a bandpass filter and temperature compensation technology, applied in the field of electromagnetic signal communication, can solve the problems of not meeting requirements, many electronic filters do not have the capacity for such large signal power, and the fcc emission mask for digital television broadcast stations is very restrictive, so as to minimize any drift in the resonant frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

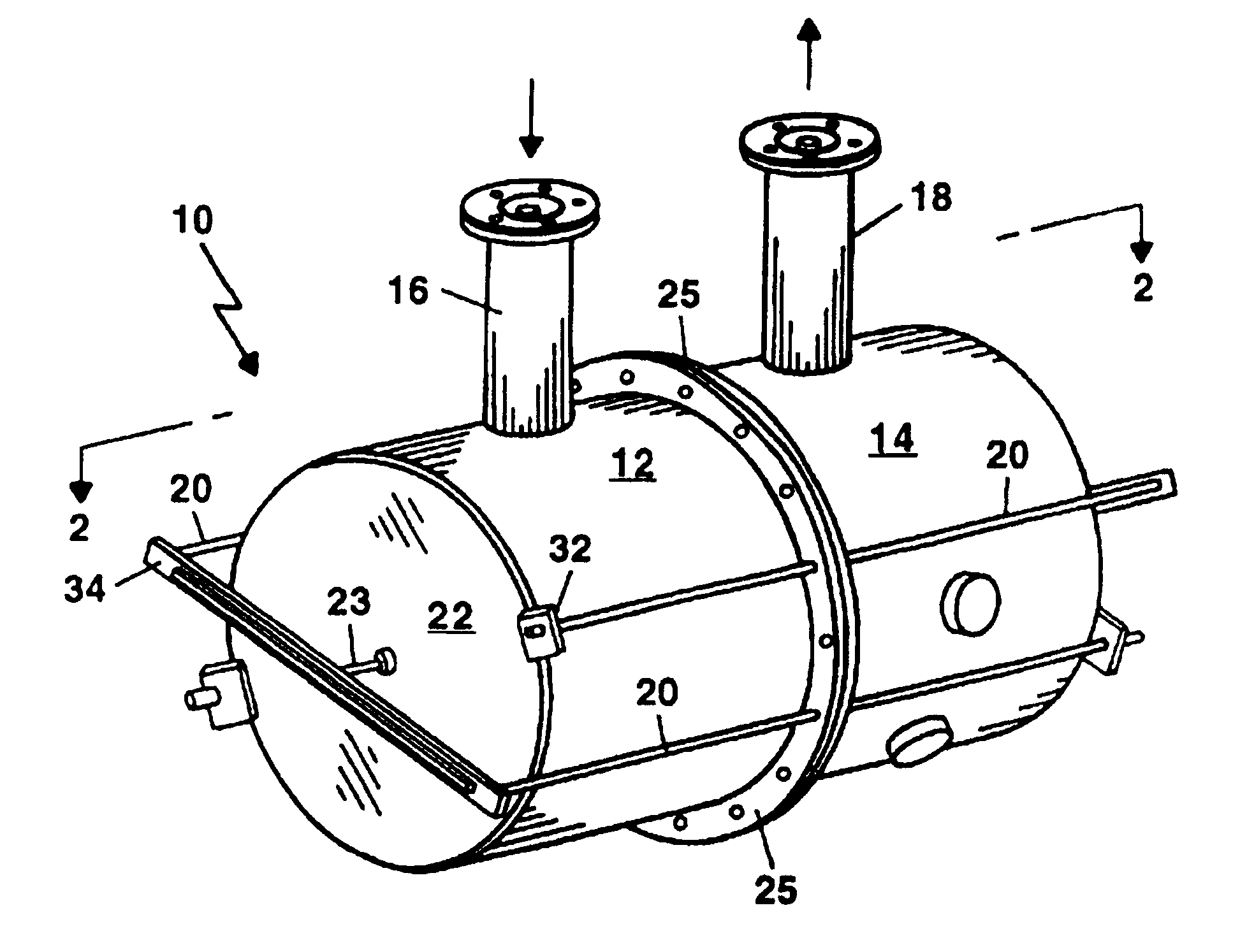

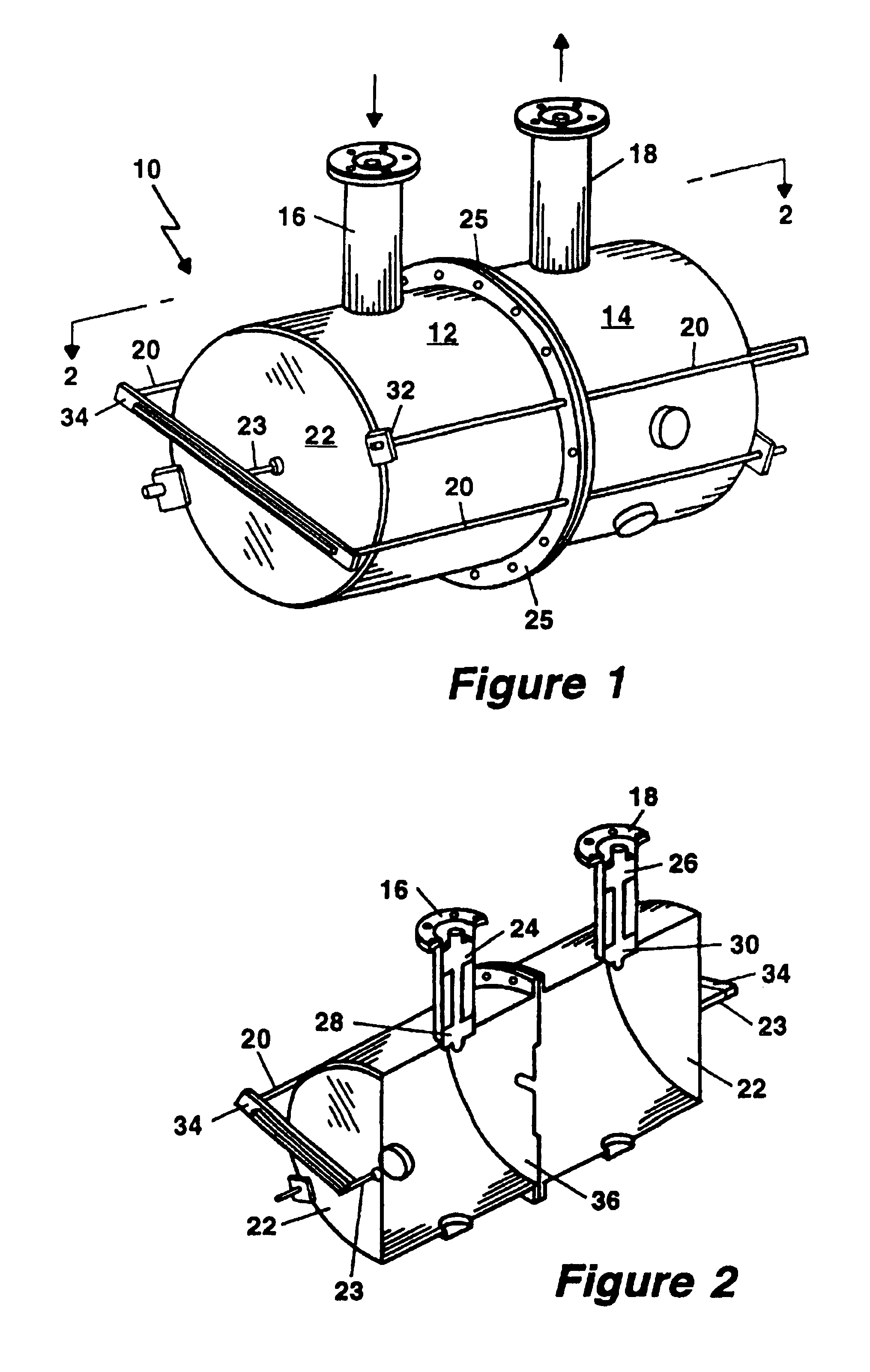

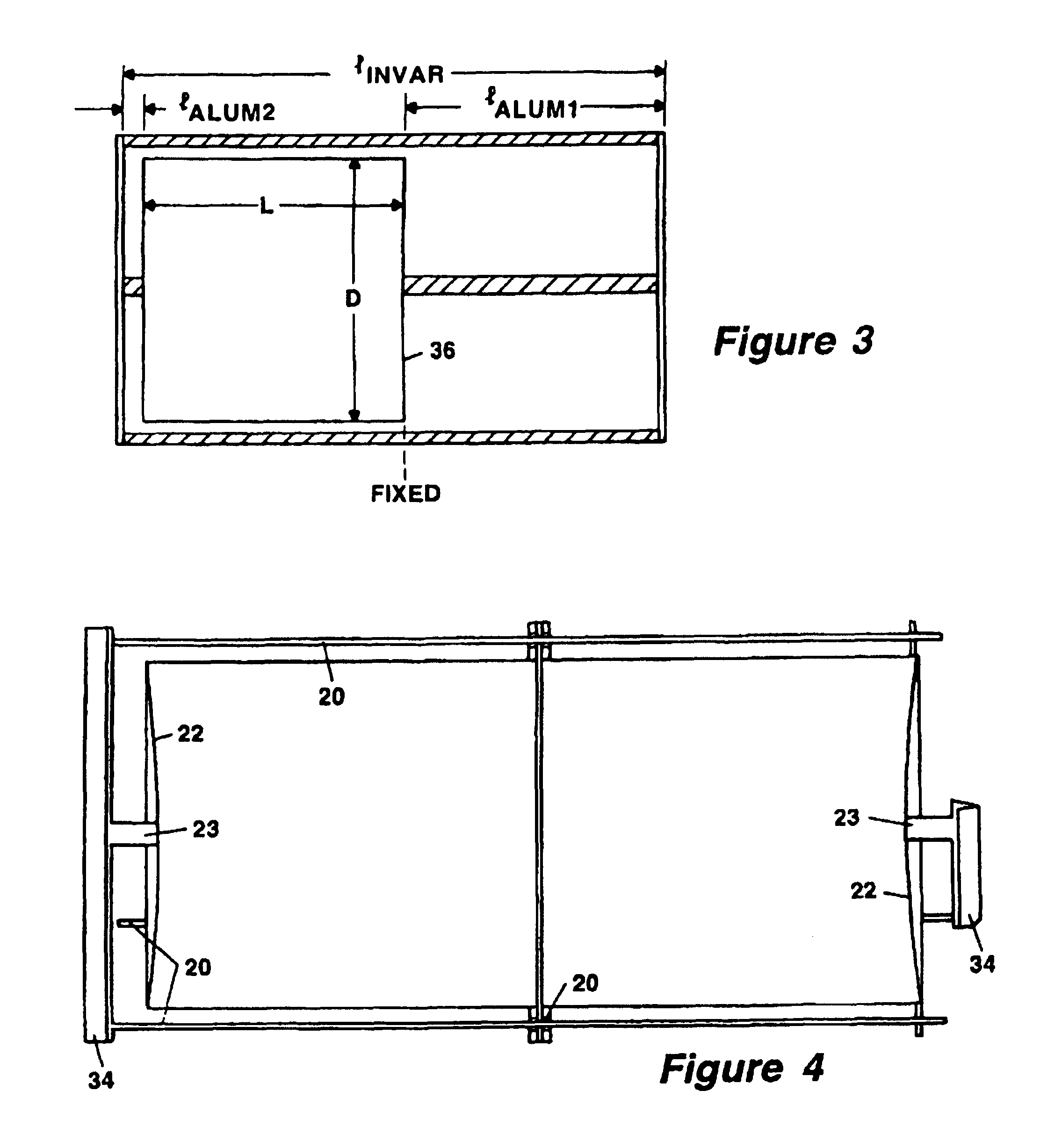

[0017]Shown in FIG. 1 is a perspective view of a temperature compensated pseudo-elliptical function mixed mode bandpass filter 10. The filter of FIG. 2 is particularly suitable for high power broadcast applications, and has an aluminum TE11 cavity consisting of cavity portion 12 and cavity portion 14. The filter 10 also has an input stage 16 containing a coaxial resonator, and an output stage 18 containing a coaxial resonator. The filter uses a set of thermal control rods to control the position of the center point of each of two cavity end plates 22 relative to an opposite end of the cylindrical cavity housing. This causes the end plates 22 to deflect when the aluminum cavity housing expands, thereby minimizing thermal drift of the filter pass band due to dimensional changes of the filter cavities.

[0018]The filter 10 is shown in cross section in FIG. 2. A coaxial cable (not shown) is connected to filter input stage 16 to allow signal input to the filter. Likewise, the filter output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com