Profile grinding machine

a profile grinding machine and profile technology, applied in the direction of grinding machines, automatic grinding control, metal-working equipment, etc., can solve the problems of elongated total time period required for grinding operations, inability to perform grinding operations, and complicated profile grinding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]Subsequently, the invention is described on its mode of embodiment with reference to the accompanying drawings so that it may be understood.

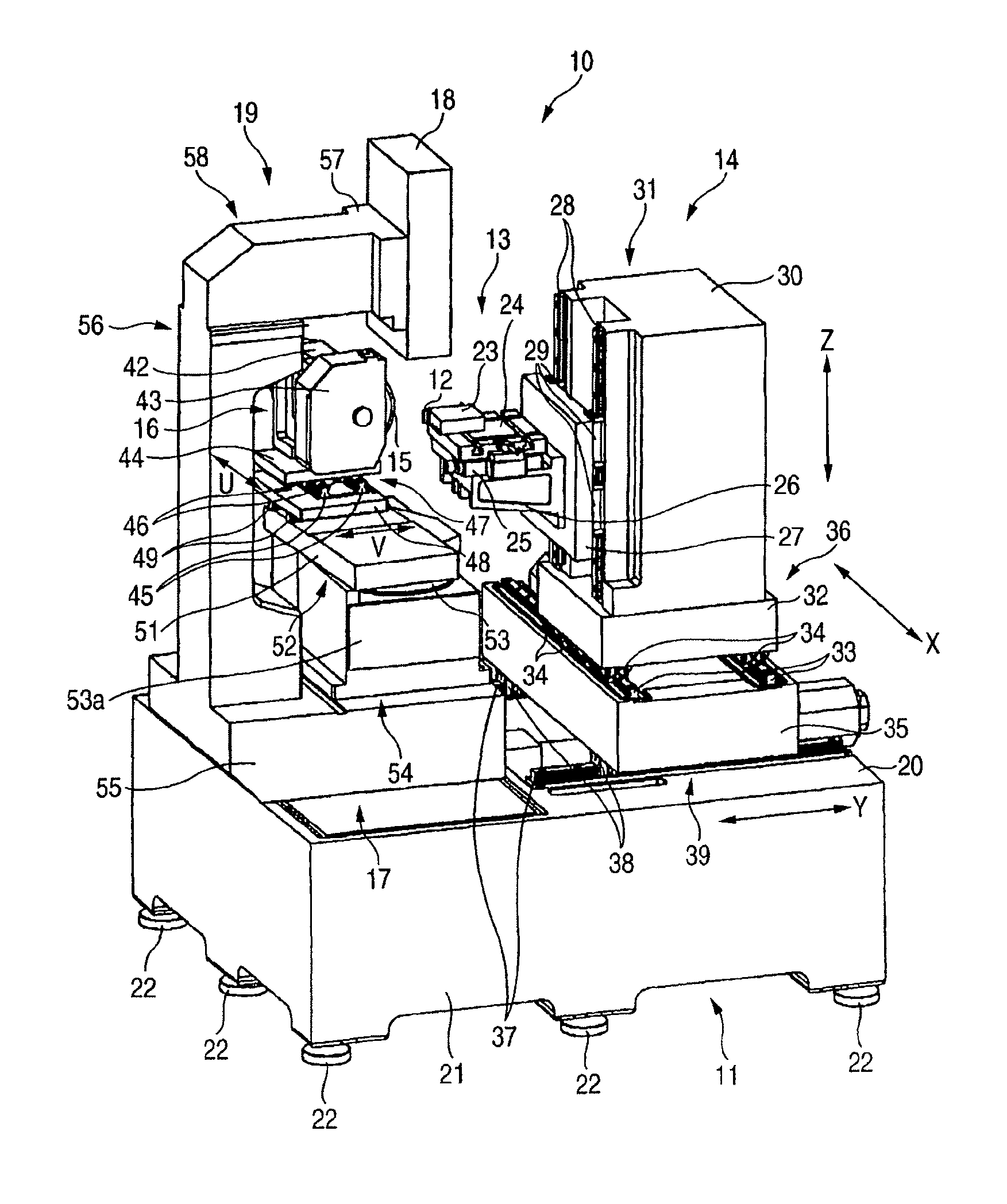

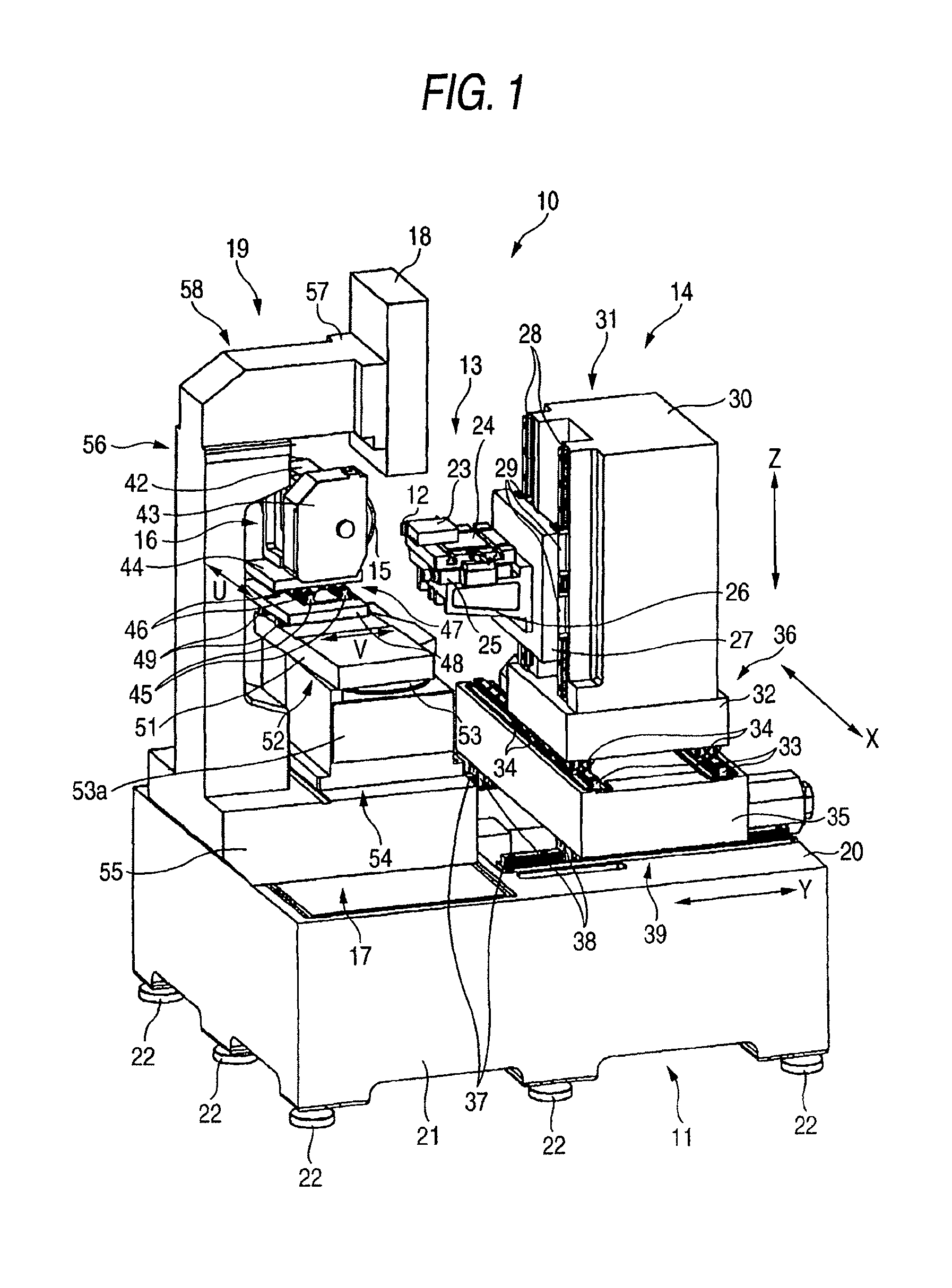

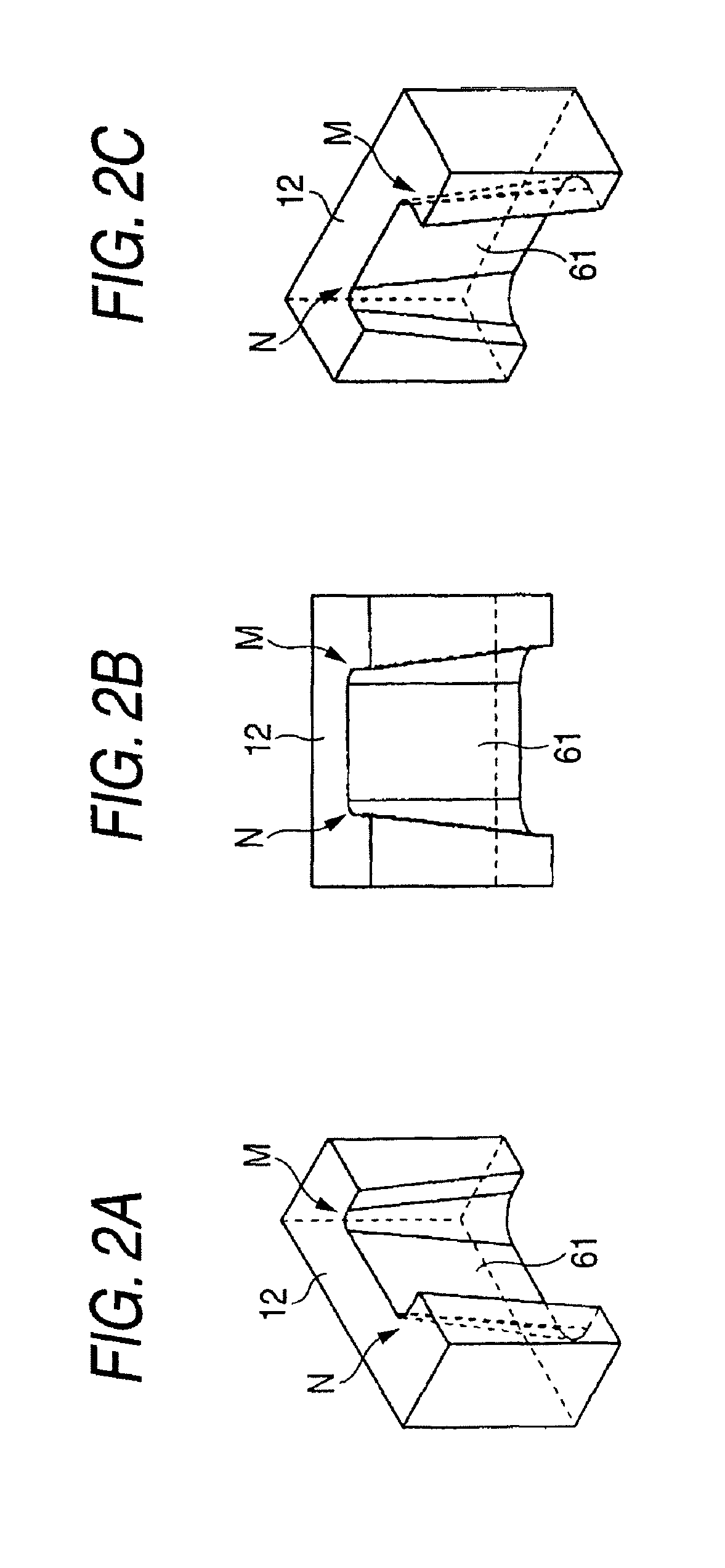

[0029]Here, FIG. 1 is a perspective view of a profile grinding machine according to one mode of embodiment of the invention; FIGS. 2A to 2C are perspective view of a work to be ground by the profile grinding machine; FIG. 3 is a perspective view of a turning mechanism, which is disposed in a grinding stone unit of the same profile grinding machine; FIG. 4 is a perspective view of an image pickup mechanism of the same profile grinding machine; FIG. 5 is a perspective view showing the situation, in which the work is ground on its face inclined in a vertical direction by the same profile grinding machine; and FIG. 6 is a top plan view showing the situation, in which the work is ground on its face inclined in a vertical direction by the same profile grinding machine.

[0030]As shown in FIG. 1, a profile grinding machine 10 includes: a base 11 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com