Electronic component and method of manufacturing the same

a technology of electronic components and manufacturing methods, applied in the field of electronic components, can solve the problems of fine metal whisker appearing on the surface, affecting and causing environmental pollution, and achieve the effect of upgrading the reliability of implemented components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0057]Now an electronic component according to the present invention will be described hereunder.

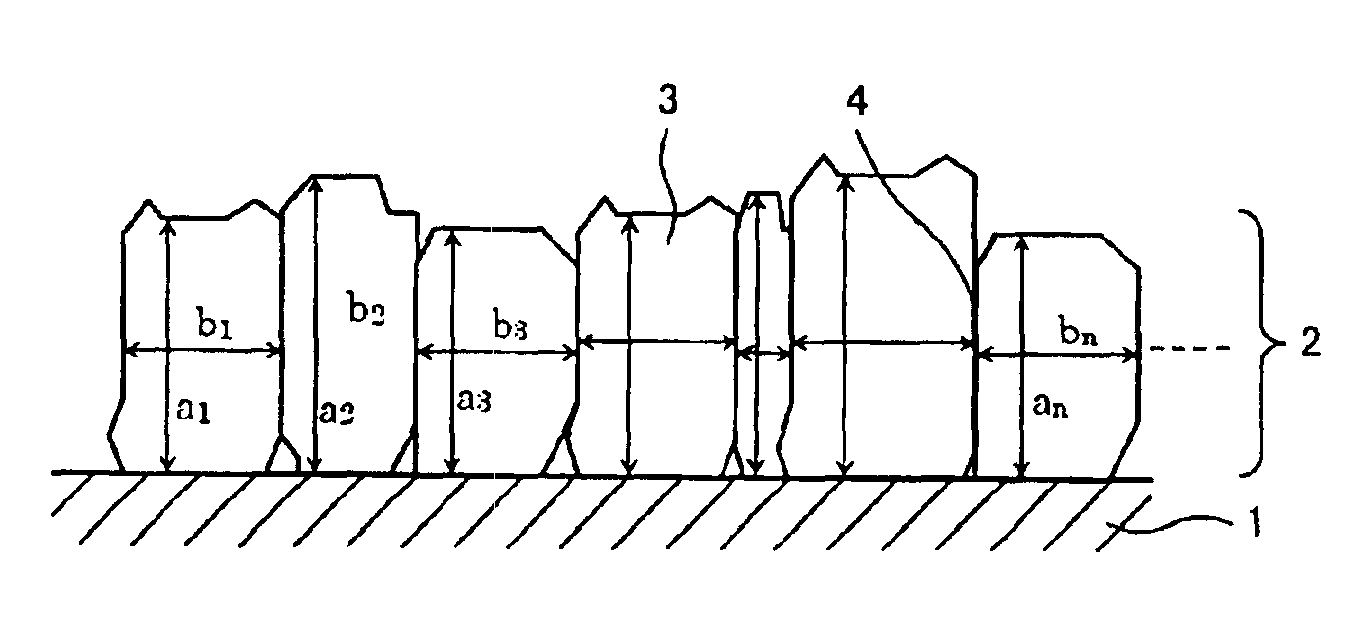

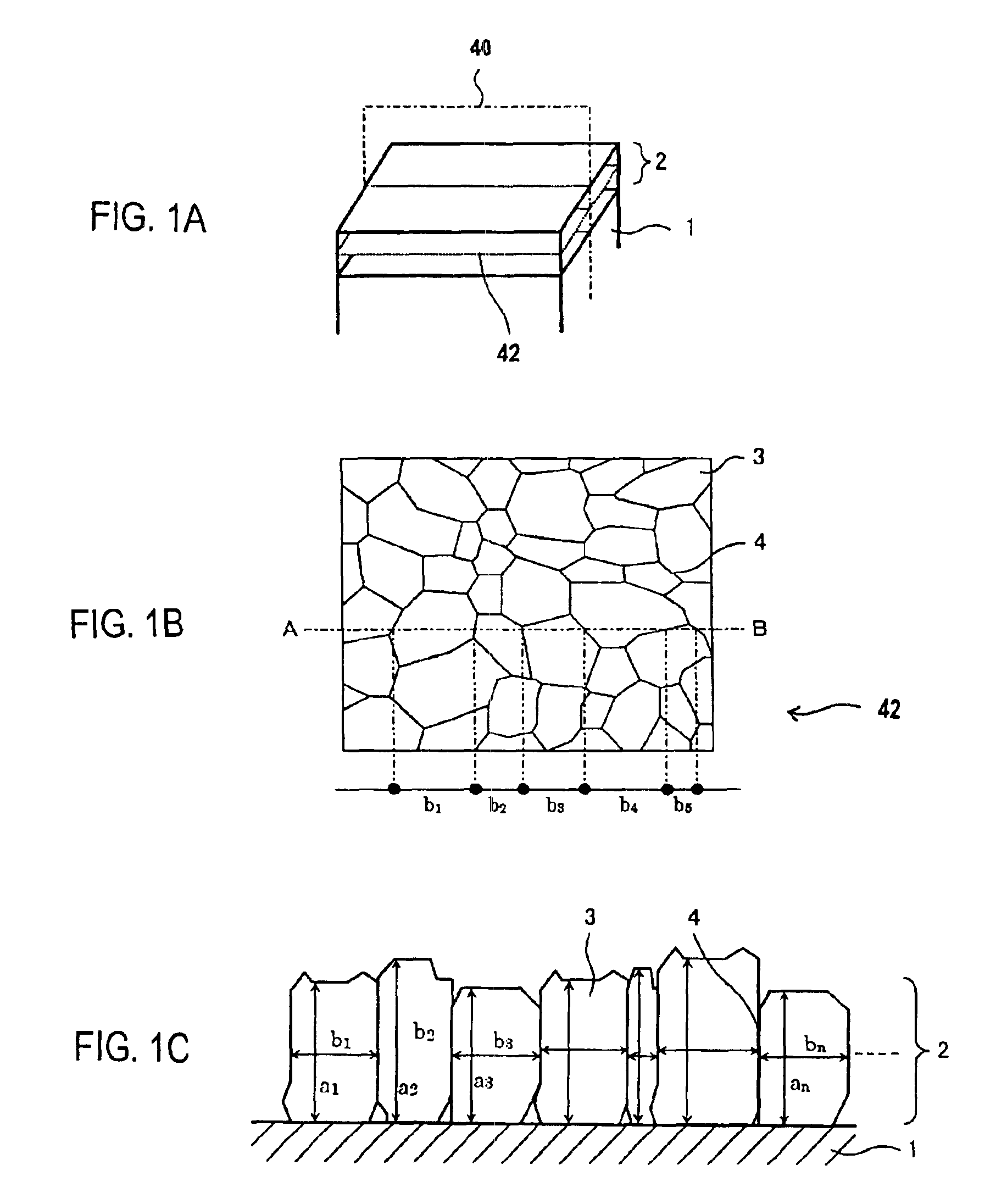

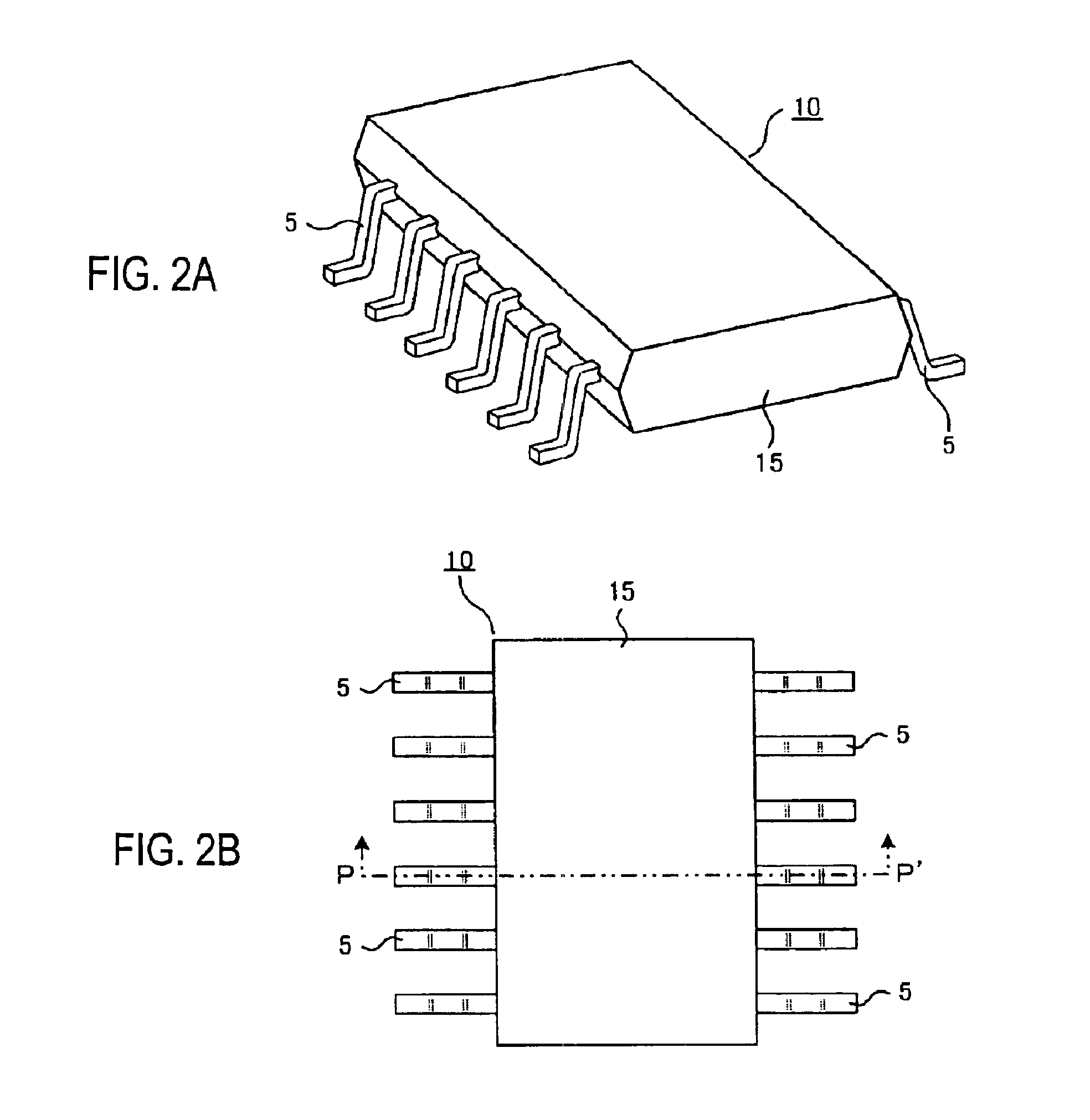

[0058]In this embodiment, a resin-sealed (plastic-packaged) integral circuit (referred to “IC”) is taken up as an example of the electronic component without limiting thereto, and description will be made on an external terminal of such IC. FIGS. 2A and 2B are schematic perspective and plan views, respectively showing the IC according to this embodiment. FIGS. 3A and 3B serve for more detailed description of the IC, and FIG. 3A is a schematic cross-sectional view taken along the line P—P′ of FIG. 2B, while FIG. 3B is an enlarged fragmentary cross-sectional drawing of an external terminal of the IC.

[0059]Referring to FIGS. 2A, 2B and 3A, 3B, the IC 10 of this embodiment is provided with a chip mounting pad 11, a semiconductor chip 12 bonded on the chip mounting pad 11 by for example an Ag paste (not shown), a metal fine wire 14 made of an Au wire or the like connecting an electrode (not s...

second embodiment

[0067]An electronic component according to the present invention will now be described hereunder.

[0068]Here, a difference of the electronic component of this embodiment from that of the first embodiment only lies in the external terminal, more specifically in a structure of the first layer in the metal thin film of the lead base material surface, and the remaining portions may be the same as the first embodiment. Accordingly, the subsequent description only refers to a structure of the first layer in the metal thin film of this embodiment. The difference from the first embodiment is that the first layer in the metal thin film has a substantially amorphous structure. Forming the first layer in an amorphous structure eliminates the continuous particle boundary, through which the Sn atoms can efficiently transfer. Therefore, even though a whisker emerges, the transference of the Sn atoms necessary for growth of the whisker is restrained, and resultantly the whisker growth is restrained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| average crystal particle diameter | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com