Centrifugal force control type variable displacement vortex type compressor

A scroll compressor and scroll technology are applied in the field of scroll compressors to achieve the effects of increasing power consumption, reducing temperature and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

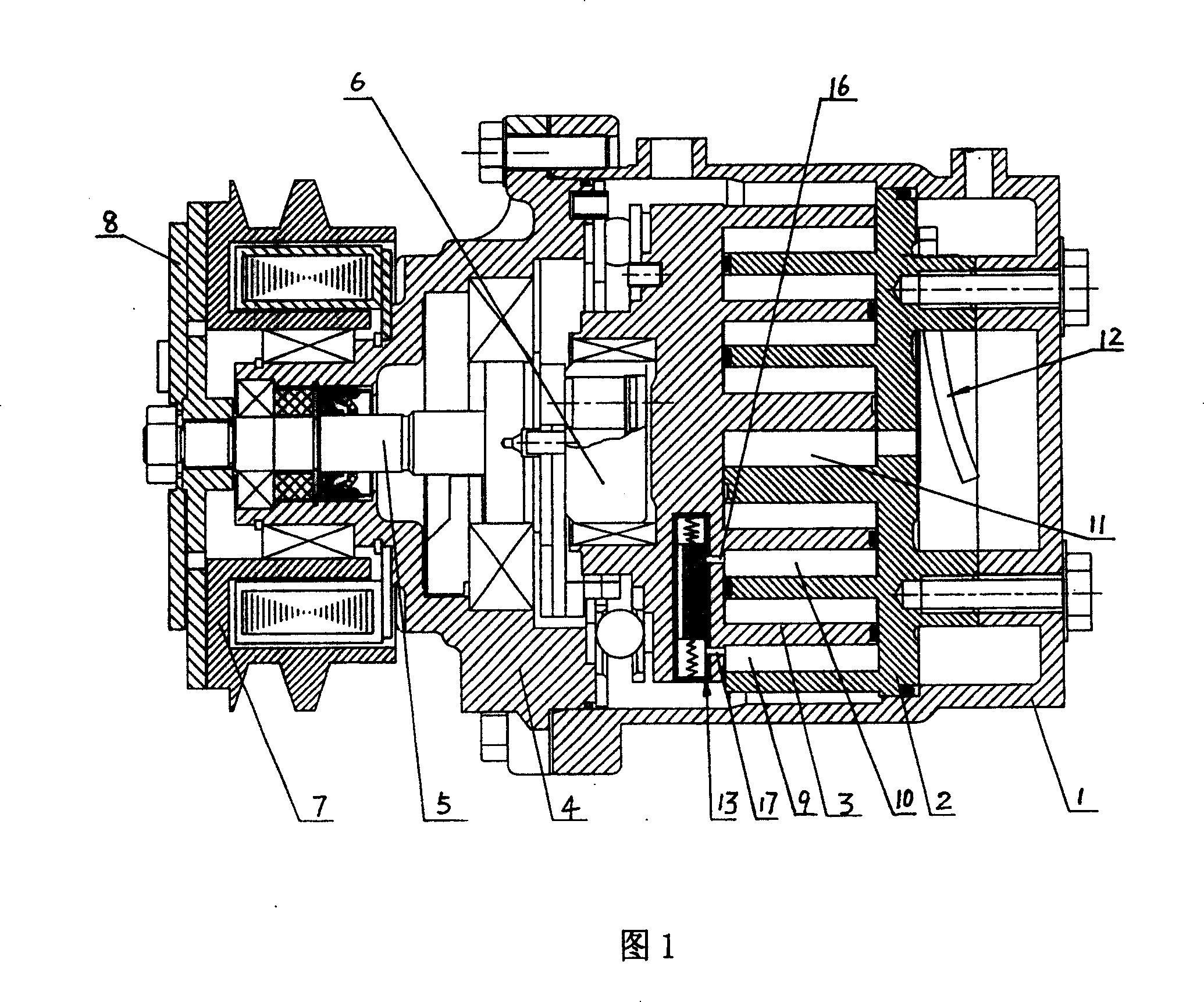

[0020] A centrifugal force-controlled variable-displacement scroll compressor, comprising a casing 1, a scroll-type static disk 2, a scroll-type moving disk 3, a front cover 4, a crankshaft 5, an eccentric sleeve 6, and a scroll-type static disk 2 Cooperate with the scroll-type moving disk 3 and install it in the casing 1, the scroll-type stationary disk 2 is fixed in the casing 1, the scroll-type moving disk 3 is connected with the eccentric sleeve 6, the eccentric sleeve 6 is connected with the crankshaft 5, and the crankshaft 5 is located in the front cover 4, the front cover 4 is connected with the housing 1, and the clutch pulley 7 is installed on the front cover 4, and the clutch pulley 7 drives the crankshaft 5 to rotate by driving the friction plate 8 installed on the crankshaft 5; the scroll type The static disc 2 cooperates with the scroll type movable disc 3 to form a crescent-shaped suction cavity 9, a crescent-shaped intermediate cavity 10, a crescent-shaped centra...

Embodiment 2

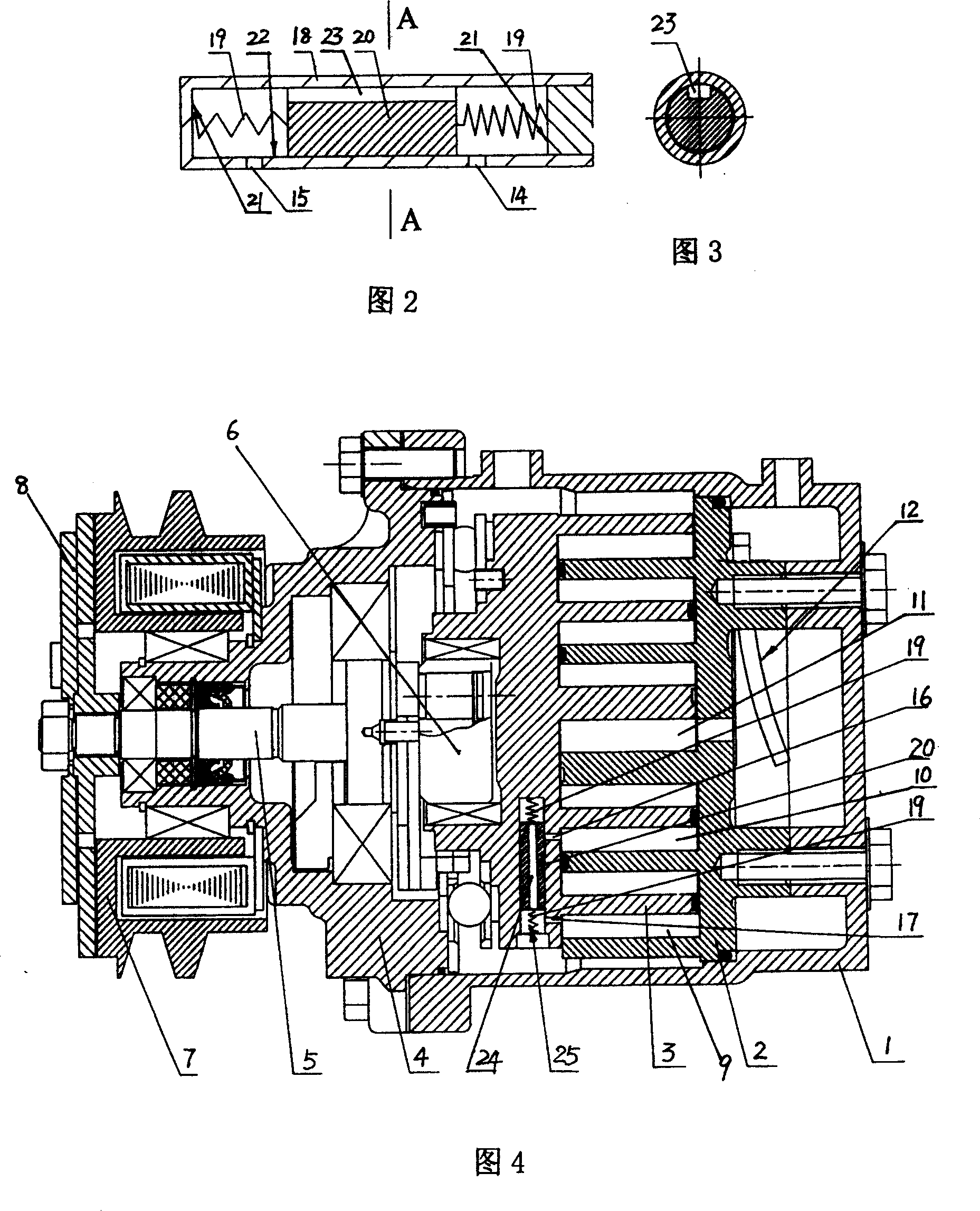

[0023] As shown in Figure 4.

[0024] A centrifugal force-controlled variable-displacement scroll compressor, comprising a casing 1, a scroll-type static disk 2, a scroll-type moving disk 3, a front cover 4, a crankshaft 5, an eccentric sleeve 6, and a scroll-type static disk 2 Cooperate with the scroll-type moving disk 3 and install it in the casing 1, the scroll-type stationary disk 2 is fixed in the casing 1, the scroll-type moving disk 3 is connected with the eccentric sleeve 6, the eccentric sleeve 6 is connected with the crankshaft 5, and the crankshaft 5 is located in the front cover 4, the front cover 4 is connected with the housing 1, and the clutch pulley 7 is installed on the front cover 4, and the clutch pulley 7 drives the crankshaft 5 to rotate by driving the friction plate 8 installed on the crankshaft 5; the scroll type The static disc 2 cooperates with the scroll type movable disc 3 to form a crescent-shaped suction cavity 9, a crescent-shaped intermediate cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com