Loop circulating gas analysis method and appts. for determining sulfur constant of combustible material

A closed-loop, gas analysis technology, applied in the direction of analyzing materials, sampling devices, material electrochemical variables, etc., can solve the problems of affecting the accuracy of measurement, difficult to measure, uneven time distribution of gas concentration, etc., to improve the accuracy, The effect of uniform gas concentration and reduced sensitivity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

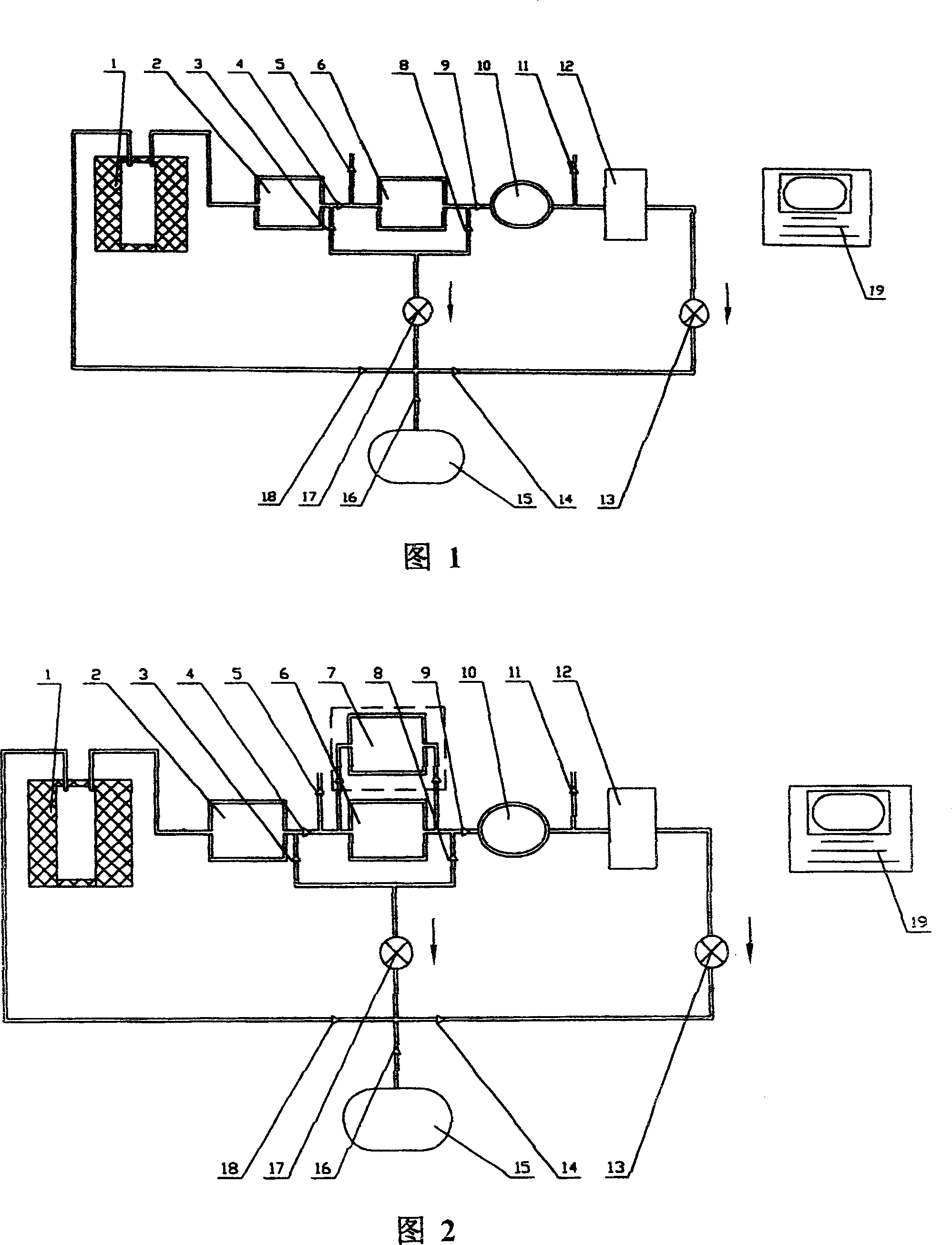

[0017] The applicant has found through research that the existing Coulomb method uses the measurement method of extracting gas while burning the sample. Since the flow of the gas adopts an open circuit, the concentration of the gas will be very uneven, which will cause the instability of the test. . The invention makes the combusted gas circulate in a closed circuit, and then controls the direction of the gas in the circuit by setting a control valve, which can solve the problem of uneven gas concentration during the test, and only a small volume of gas is extracted during the measurement. That is, the technical effect to be achieved by the present invention is achieved. The specific method of the present invention is: establish a connecting pipe to communicate with the sample reaction furnace, and at the same time, one or more gas chambers, gas valves, filters, air pumps and electrolytic cells for measurement are arranged on the pipeline, and each gas chamber, The gas valve,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com