Electromagnetically actuated valve

A solenoid valve and valve body technology, which is applied in the field of solenoid valves, can solve the problems of increasing working noise of air and difficulty in removing air, and achieve the effect of effectively removing air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

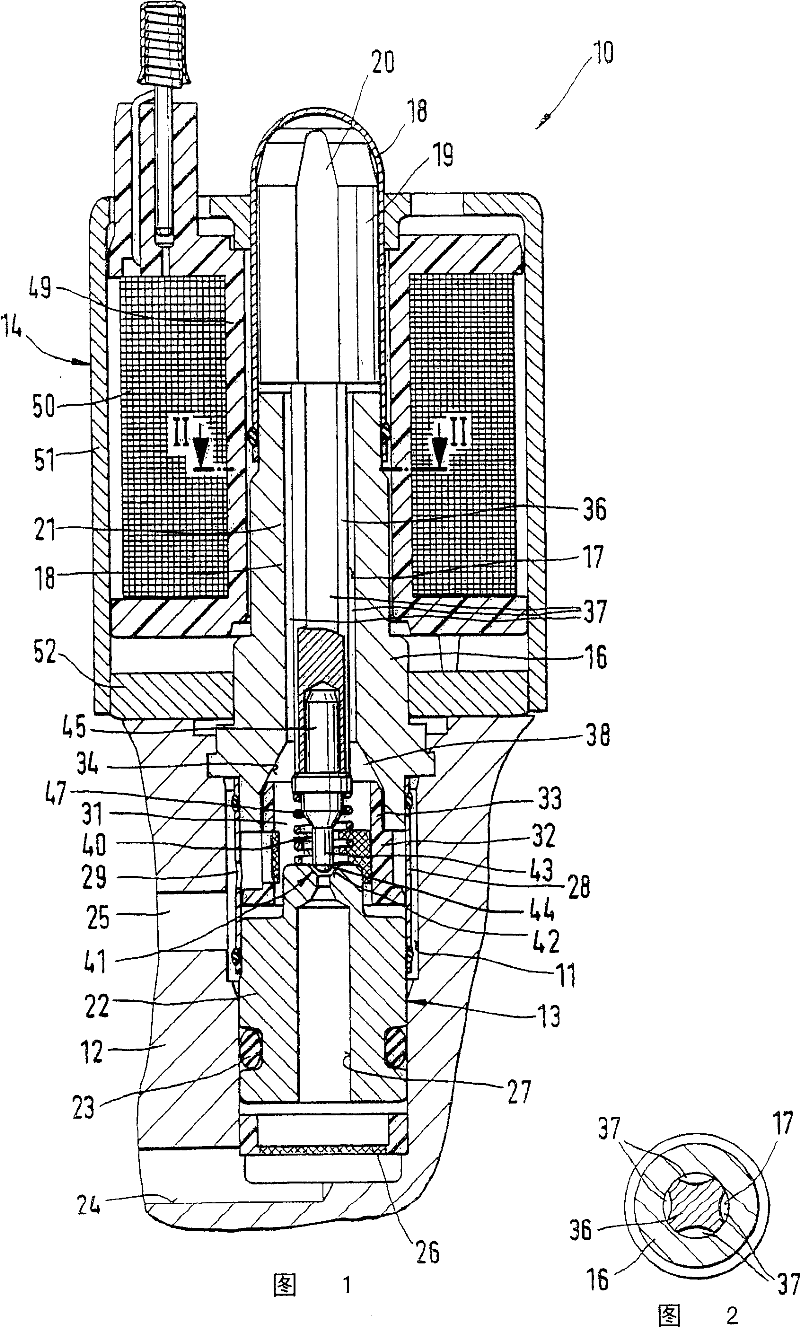

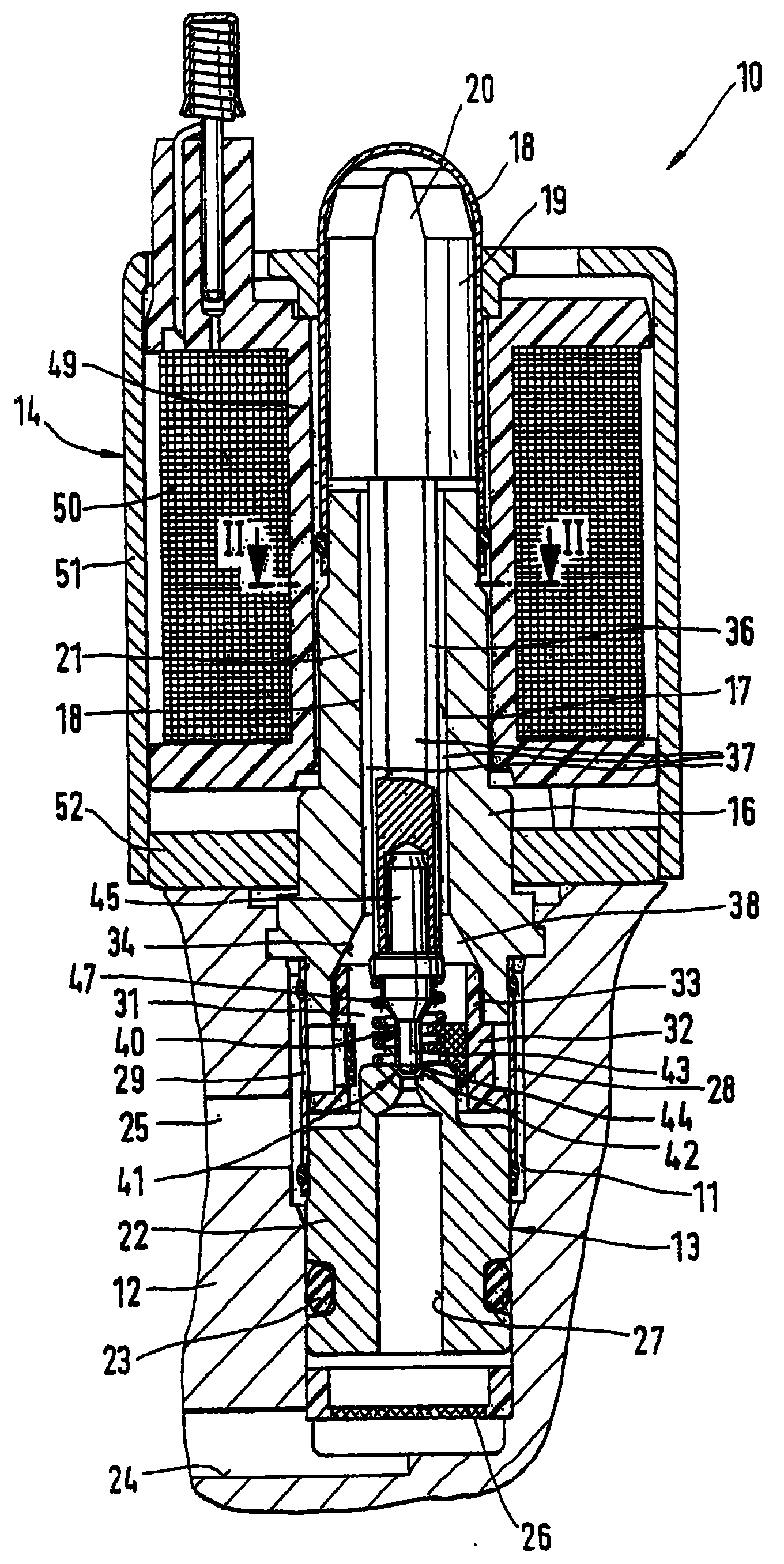

[0009] The electromagnetic valve 10 that is used for automobile hydraulic braking system shown in Fig. 1 is mainly made of two assemblies: a hydraulic component 13 that is fixed in a stepped hole 11 of valve unit 12 and an electric component that is placed on this hydraulic component 14.

[0010] The hydraulic component 13 has a valve body 16 with a through longitudinal bore 17 . On the side of the electrical component 14 , a valve housing 18 is fastened to the valve body 16 . An armature 19 is housed in the valve housing 18 , displaceable longitudinally and having a longitudinal groove 20 .

[0011] A valve seat part 22 with a circumferentially arranged sealing ring 23 is accommodated in the stepped bore 11 of the valve unit 12 . The sealing ring separates an inlet opening 24 from an outlet opening 25 of the valve unit 12 . On the side of the inflow opening 24 there is a filter disk 26 in the stepped opening 11 . The valve seat part 22 with a longitudinal bore 27 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com