Reinforced osseous porcelain and process for producing same

A production process and a technology for strengthening porcelain, which is applied in the field of bone-reinforced porcelain and its production process, can solve the problems of high flexural strength, low flexural strength, poor light transmission, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A bone-reinforced porcelain, the green body of which consists of the following components (% by weight): Longyan washed mud 47.0, Hunan feldspar 14.0, Guizhou clay 6.5, α-alumina powder 22.5 and synthetic bone powder 10.0.

[0021] Described Longyan washing mud is following component (by weight %): SiO 2 60.00, Al 2 o 3 27.50 Fe 2 o 3 0.40, TiO 2 0.04, CaO 0.11, MgO 0.29, K 2 O 4.80, Na 2 O 0.33 and IL 7.00.

[0022] Described Guizhou clay is following composition (by weight %): SiO 2 45.79, Al 2 o 3 38.79 Fe 2 o 3 0.17, TiO 2 0.06, CaO 0.46, MgO 0.02, K 2 O 0.02, Na 2 O 0.02 and IL 14.00.

[0023] The particle size of the α-alumina powder is 3 μm.

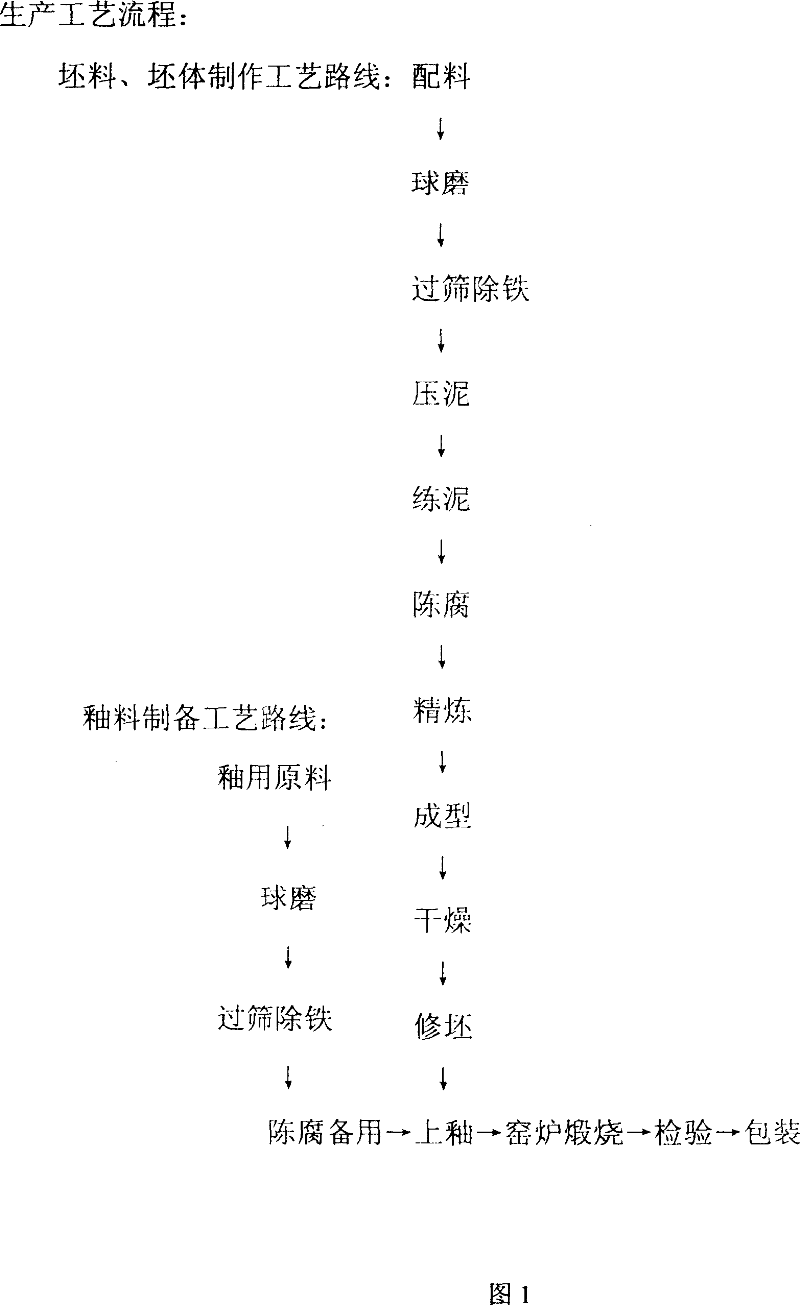

[0024] The production technology of bone reinforced porcelain of the present invention is the following steps:

[0025] Billet and green body production: put Longyan mud washing, Hunan feldspar, Guizhou clay, α-alumina powder and synthetic bone powder into the ball mill according to the proportion, ad...

Embodiment 2

[0031] A bone-reinforced porcelain, the green body of which consists of the following components (% by weight): 45% of Longyan washing mud, 15% of Hunan feldspar, 8% of Guizhou clay, 24% of α-alumina powder and 8% of synthetic bone powder.

[0032] Described Longyan washing mud is following component (by weight %): SiO 2 56.00, Al 2 o 3 28.00, Fe 2 o 3 0.30, TiO 2 0.03, CaO 0.15, MgO 0.33, K 2 O 5.40, Na 2 O 0.36 and IL 8.00.

[0033] Described Guizhou clay is following composition (by weight %): SiO 2 50.00, Al 2 o 3 35.00, Fe 2 o 3 0.14, TiO 2 0.05, CaO 0.40, MgO 0.01, K 2 O 0.03, Na 2 O 0.03 and IL 14.50.

[0034] The particle size of the α-alumina powder is 4 μm.

[0035] The production technology of bone reinforced porcelain of the present invention is the following steps:

[0036] Billet and green body production: Put Longyan mud washing, Hunan feldspar, Guizhou clay, α-alumina powder and synthetic bone powder into the ball mill according to the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com