Francis wheel and hydraulic machine therewith

A runner and turbine technology, applied in the field of hydraulic machinery, can solve problems such as deterioration and unresearched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

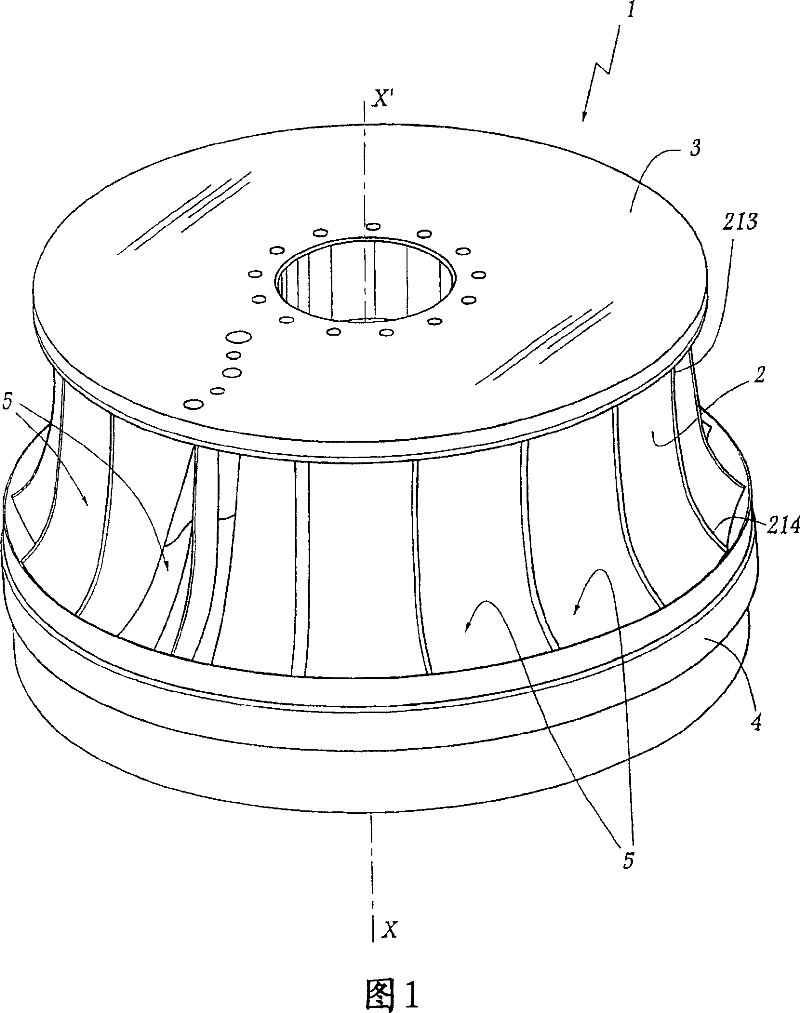

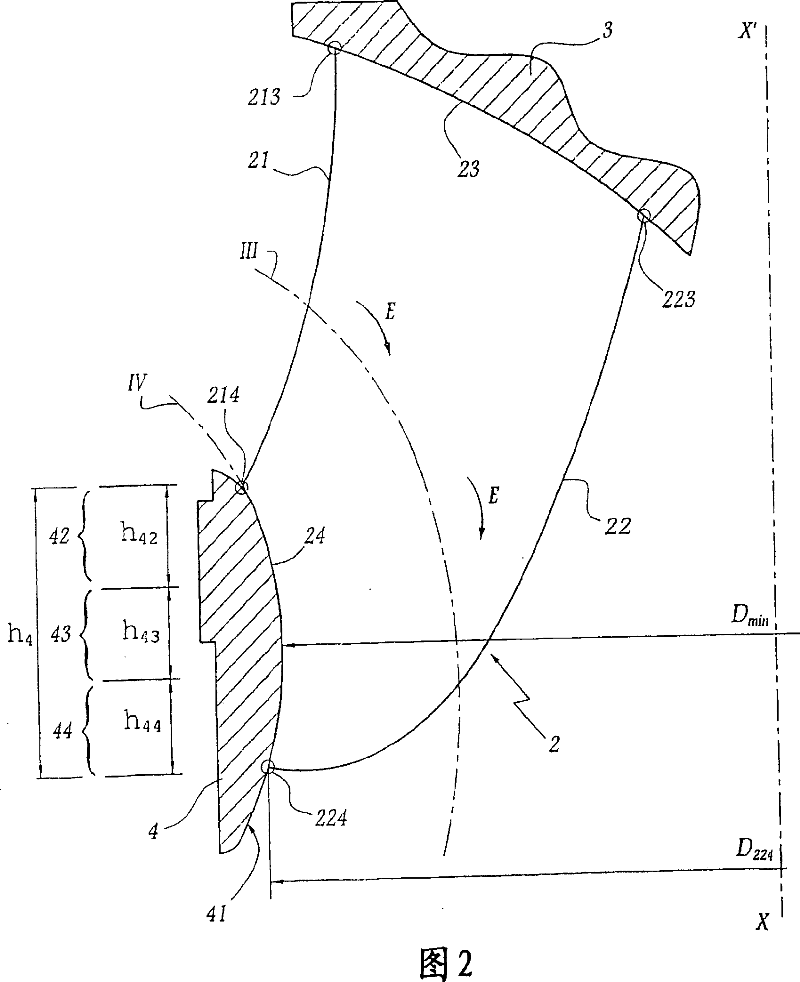

[0029] [29] The runner 1 shown in FIGS. 1 to 5 comprises a number of identical blades 2 distributed around the central axis of rotation X-X' of the runner 1 . A top plate 3 is arranged on the radially inner upper portion of the runner 1 , and the tire 4 is located on the edge of the radially outer lower portion of the blade 2 . Thus, a flow channel 5 is formed between each pair of adjacent blades, this channel being delimited by the top plate 3 and the rim 4 .

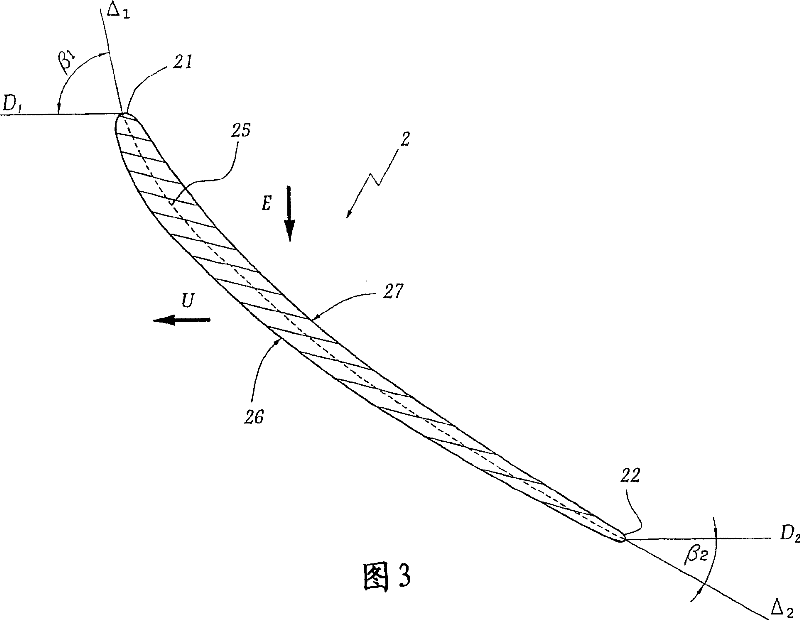

[0030] [30] Reference numeral 21 designates the flow edge of the blade 2 . 22 designates the runoff edge of the blade. 213 represents the joining point of the spoiler edge 21 and the top plate 3 . 214 represents the joining point of the spoiler edge 21 and the tire 4 . 223 refers to the joint point of the flow edge 22 and the top plate 3 , and the reference number 224 represents the joint point of the flow edge 22 and the tire 4 .

[0031] [31] Line III in FIG. 2 represents the meridian trajectory of the vortex of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com