Internal combustion engine and method of operating the internal combustion engine

An internal combustion engine, operating state technology, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., to achieve the effect of high efficiency conversion and low emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

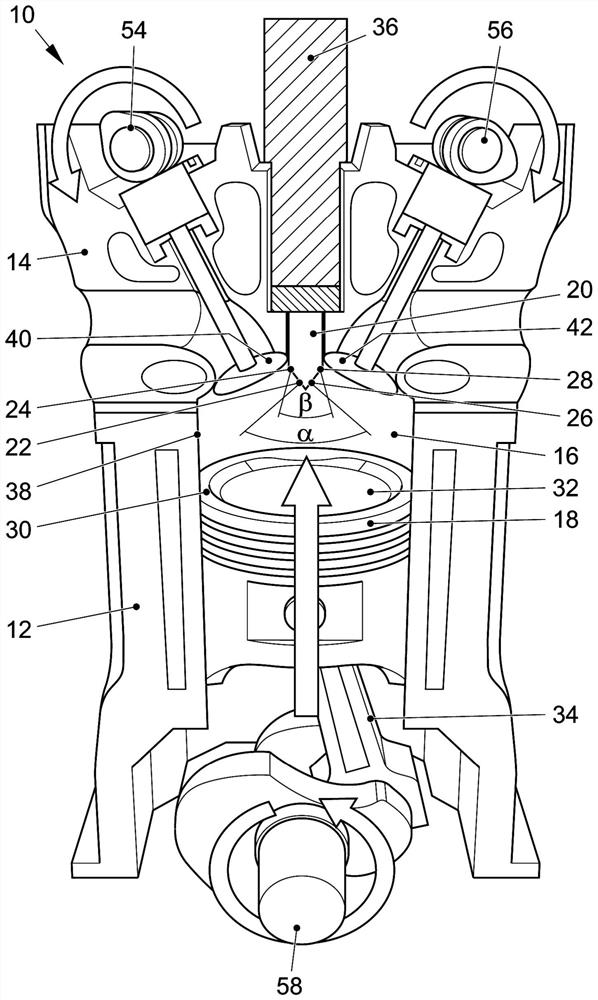

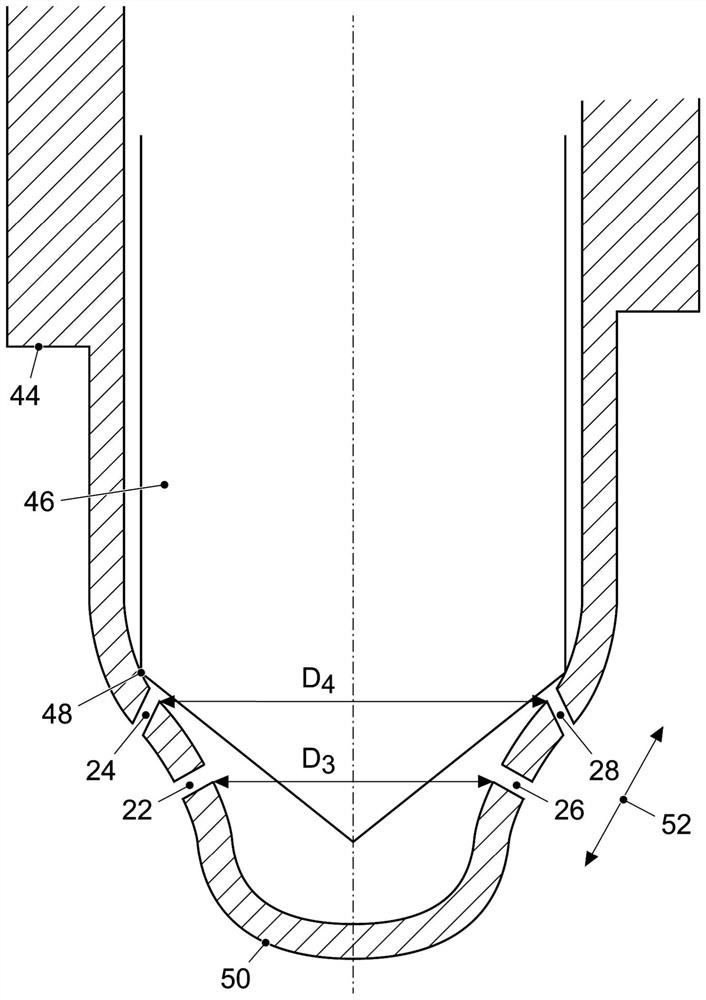

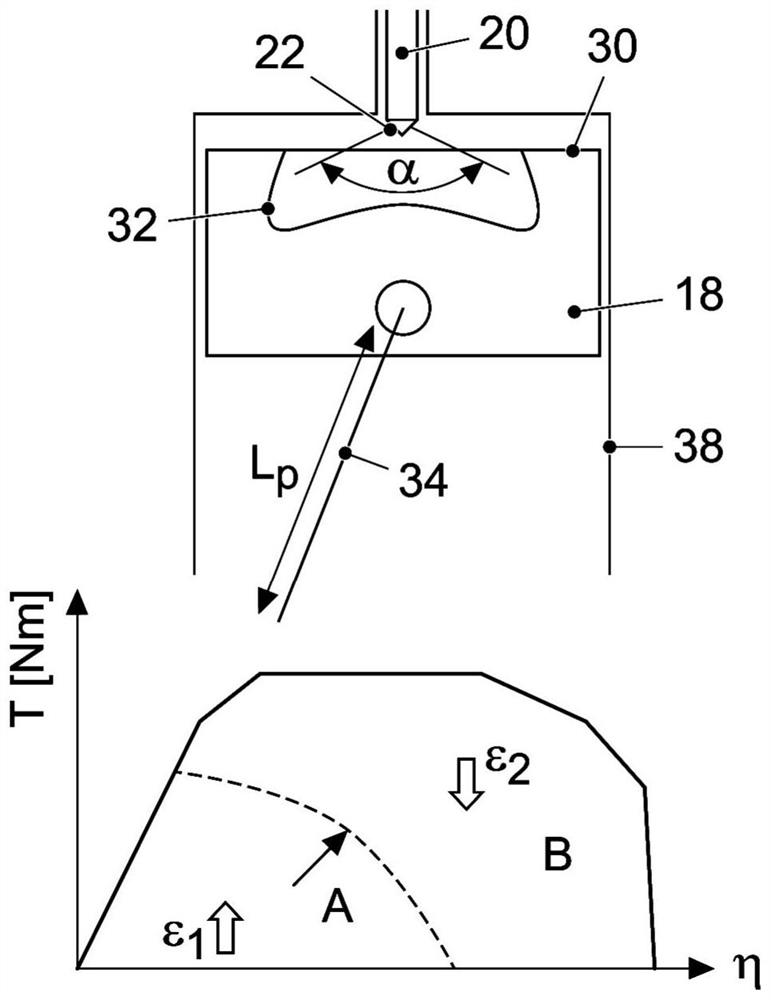

[0027] figure 1An internal combustion engine 10 according to the invention is shown schematically. The internal combustion engine 10 has an engine block 12 and a cylinder head 14 connected to the engine block 12 , wherein a piston 18 is arranged in a cylinder bore of the engine block 12 and is connected to a crankshaft 58 via a connecting rod 34 . The cylinder bore represents a cylinder wall 38 on which the piston 18 is guided in a known manner by means of piston rings. Piston 18 and cylinder head 14 delimit combustion chamber 16 of internal combustion engine 10 . In addition, intake and exhaust ducts are formed in the cylinder head 14 for the gas exchange of the combustion chamber 16 , wherein the respective ducts can be closed by means of an intake valve 40 or an exhaust valve 42 to flow into or out of the combustion chamber 16 temporarily interrupted. To open the intake valve 40 , an intake camshaft 54 is provided, the cams of which press the intake valve 40 in the dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com