Blackbody furnace-producing material and heating furnace

A heating furnace and furnace wall technology, applied in the field of heating furnace kiln, can solve the problems of low heat ray penetration rate, little increase in heat transfer area, low energy saving rate, etc., to improve the penetration rate and irradiance, and the vertical temperature difference of the furnace The effect of reducing and improving the uniformity of furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

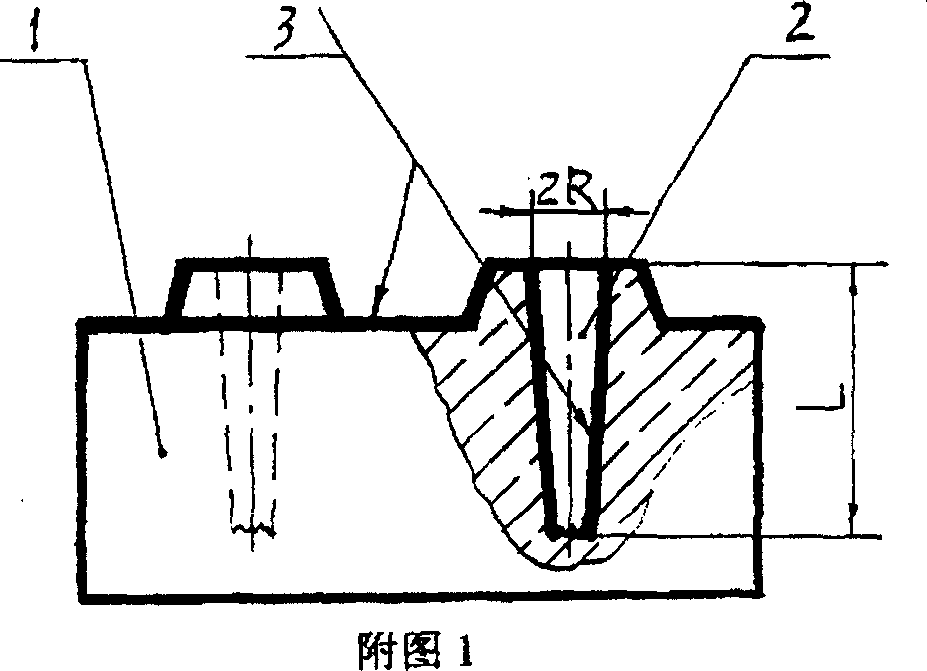

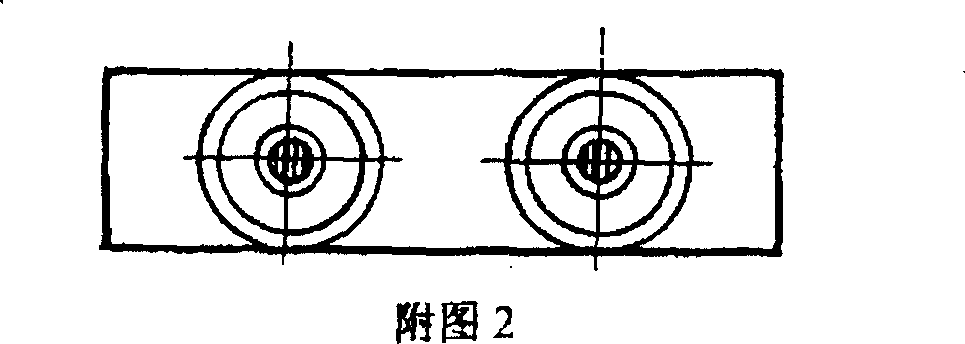

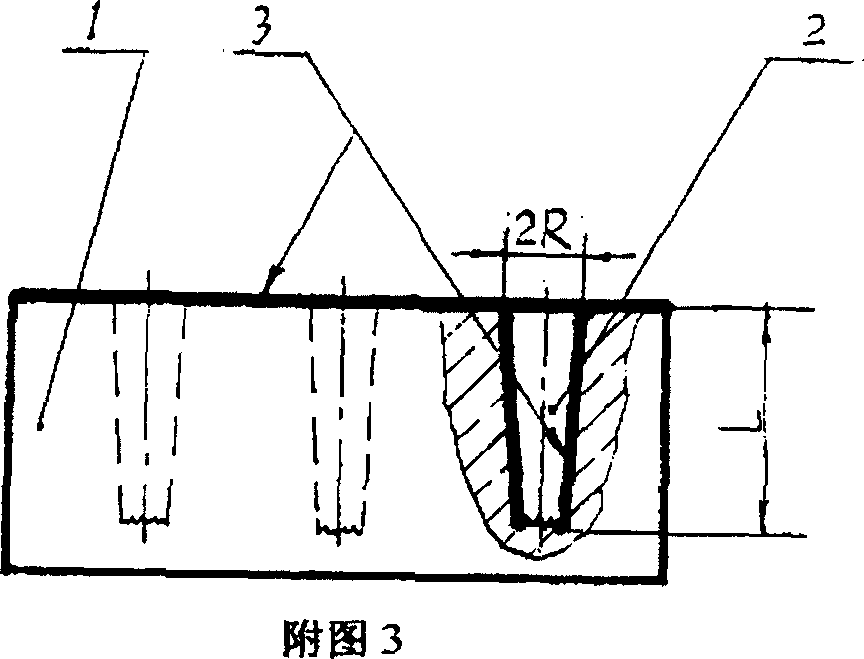

[0027] In the figure, the blackbody is a cavity cone, and the cone has a certain length-to-diameter ratio L / R; in order to ensure that each blackbody radiates enough energy to meet the needs of industry, the cone must have the necessary opening area; A high-emissivity layer is sintered on the surface of the cavity cone, and the material of the high-emissivity layer is blackened zirconium, zirconium, iron, silicon carbide, and rare earth, combined with a binder, and completed at 850°C Sintering; the surface of the truncated cone should maintain a certain roughness; the bottom of the truncated cone has a wavy pit to increase the emissivity. The black body can be set on the refractory bricks for building the furnace wall first, and can also be set at the same time in the process of building the furnace wall by other methods, such as directly on the rammed, poured furnace wall and its prefabricated parts. The brick or furnace wall faces the side of the furnace, and is also sintere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com