Attractor

An attractor and shell technology, which is applied to fishing accessories, fishing, manipulators, etc., can solve the problems of increased cost, reduced manufacturing efficiency of the attractor, and difficulty in miniaturizing the attractor, and achieves a simple structure, improved thermal efficiency, etc. The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

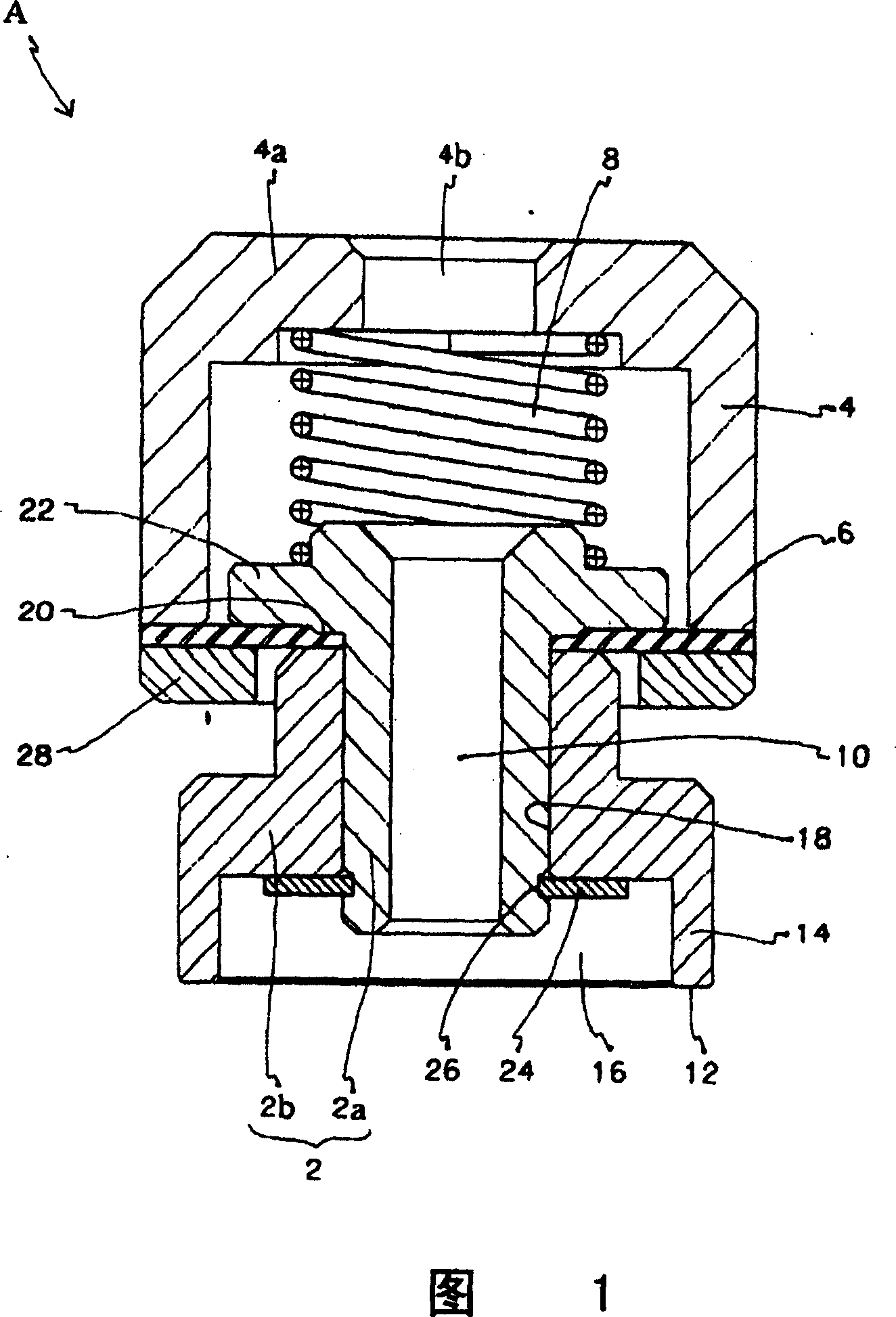

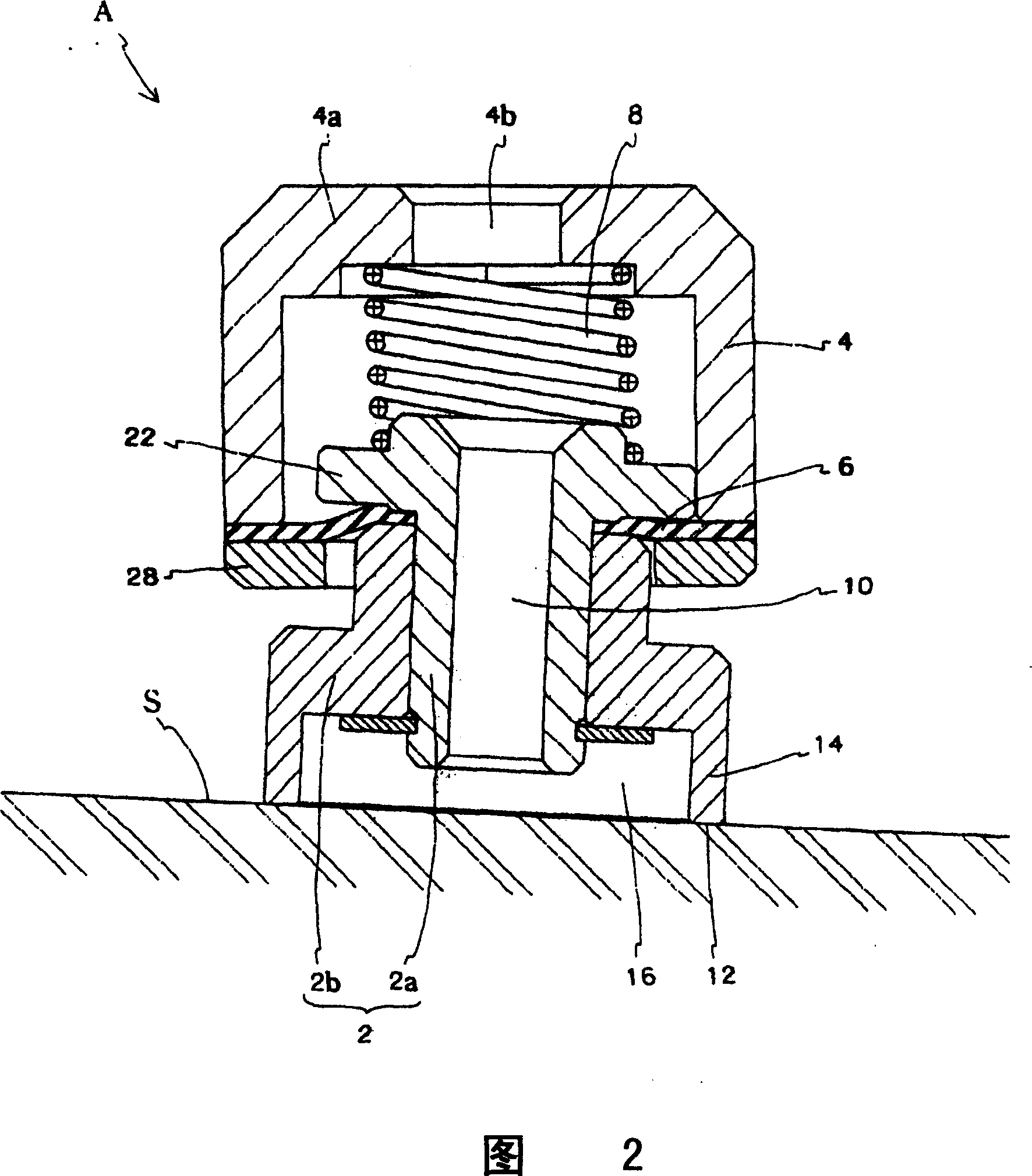

[0026] Fig. 1 is a side sectional view of an embodiment of an aspirator A of the present invention.

[0027] The suction device A includes a suction portion 2, a housing 4, a thin-plate-shaped rubber member 6 made of synthetic rubber as a thin-plate-shaped elastic member, and a spring 8 as a biasing member.

[0028] The suction portion 2 includes a cylindrical member 2a having a through hole 10, and a skirt member 2b in which a contact portion 12 is formed at one end. The contact portion 12 contacts the workpiece when the attraction portion 2 attracts and holds the workpiece.

[0029] A circular protrusion 14 is formed at one end of the skirt member 2b. The through hole 18 communicates with the concave portion 16 surrounded by the circular protrusion 14 and the other end 20 of the skirt 2b.

[0030] The outer diameter of the cylindrical part 2a is almos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com