Fiber or fabric for shielding electromagnetic wave and preventing ultraviolet, and preparation method thereof

An anti-ultraviolet and electromagnetic wave technology, applied in the direction of fiber type, fiber treatment, natural fiber, etc., can solve the problems of weak combination of colloidal solution and fabric, poor shielding and anti-ultraviolet function, and easy shedding of colloidal solution, so as to achieve good ultraviolet shielding Effect, stable washing fastness, and the effect of improving blood viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A. Use FeCl with a concentration of 43.4mmol / l at 80°C 3 The solution was adjusted to pH 1.7 with NaOH and HCl solution, and hydrolyzed to α-Fe 2 o 3 Colloidal solution;

[0040] B. Treat the polyester fiber at 100°C for 2 hours in the dyeing machine;

[0041] C. Bake at 120°C for 8 hours.

[0042] According to SJ20524-95 "Test Method for Material Shielding Effectiveness", the electromagnetic shielding effectiveness test is carried out on polyester treated at 100 °C. This standard is an electronic industry standard, and it is the same as the test method of ASTM4935 in the United States. Select 30MHz, 100MHz, 300MHz and 1000MHz respectively. The shielding effectiveness value is tested under the frequency. These four frequencies basically represent the electromagnetic wave radiation frequencies that people often encounter in life. 30MHz is a critical frequency value, and the radiation frequency of general household appliances is above 30MHz. The radiation frequency o...

Embodiment 2

[0046] Study on UV shielding effect

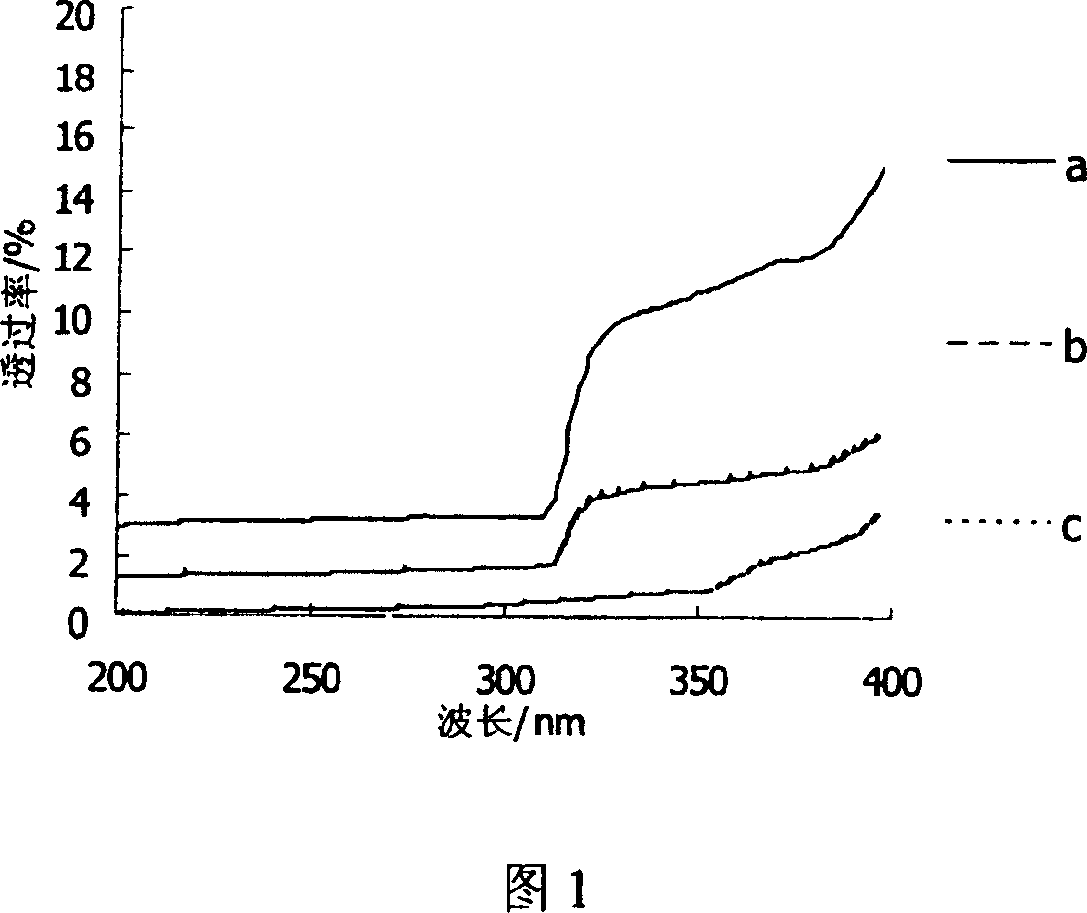

[0047] Use FeCl with a concentration of 6.2mmol / l (1#) and 24.8mmol / l (2#) at 60°C 3 120ml of the solution was used to prepare the required colloidal solution, and polyester (6cm*10cm) was treated at 130°C for 2 hours in an infrared high-temperature and high-pressure dyeing machine, and then baked at 180°C for 8 hours. Test the UV transmittance before and after finishing the polyester, as shown in Figure 1.

[0048] It can be seen from Figure 1 that after ultrafine α-Fe 2 o 3 The UV transmittance of polyester treated with colloidal solution is significantly reduced, and it has a good anti-ultraviolet effect, and the greater the concentration, the better the effect. With 24.8mmol / l FeCl 3 α-Fe 2 o 3 The ultraviolet transmittance of the colloid solution treated polyester is below 1% in the range of 200-350nm.

Embodiment 3

[0050] Effect of Soaping on the UV Shielding Effect of Fabrics

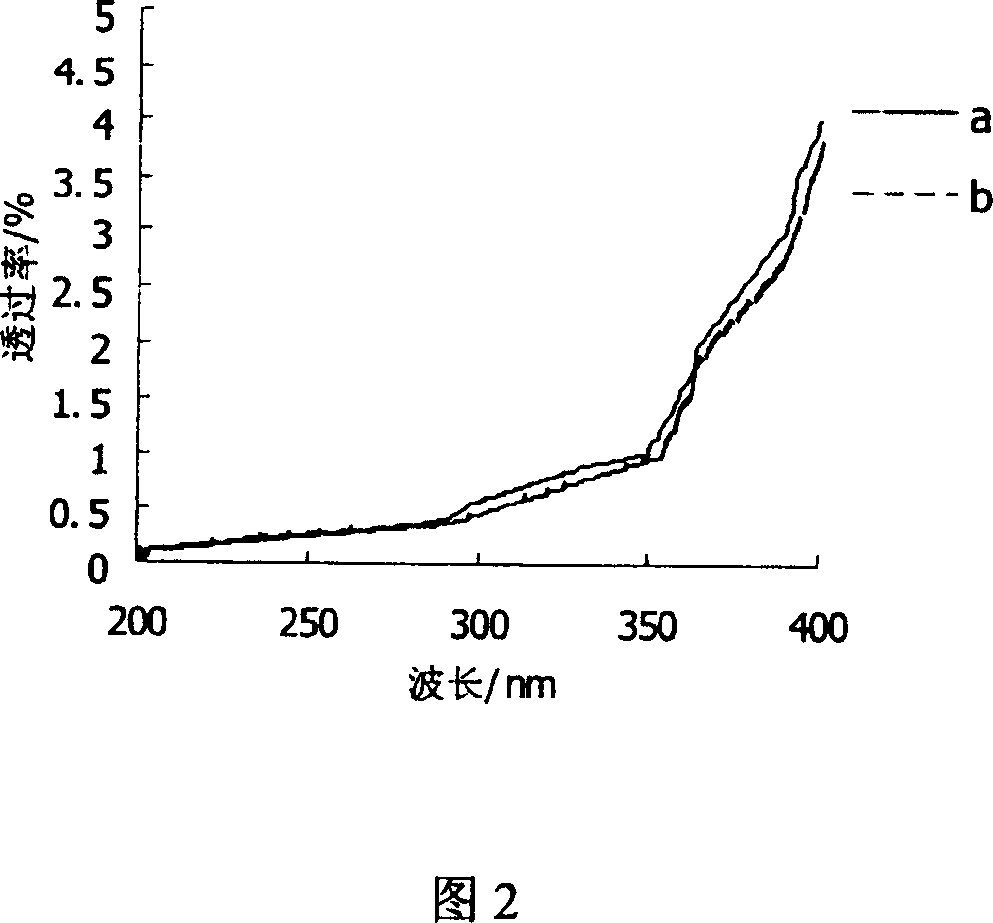

[0051] Concentration is the FeCl of 24.8mmol / l (2#) among the embodiment 2 3 The polyester treated with the colloidal solution prepared by the solution 120ml was washed with 100ml of 5g / l standard soap solution at 40°C for 30min. The comparison of the ultraviolet transmittance before and after washing is shown in Figure 2 below.

[0052] It can be found from Figure 2 that the UV shielding effect of the fabric is almost unchanged, indicating that the ultrafine α-Fe 2 o 3 The particles have better fastness in polyester and have better washing resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com