Non contact rotatable electric energy transfer device

A power transmission, non-contact technology, applied in electromechanical devices, electrical components, irreversible AC power input into DC power output and other directions, can solve the problems of poor mechanical strength, limited rotation angle, low power, etc., to achieve a solid structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

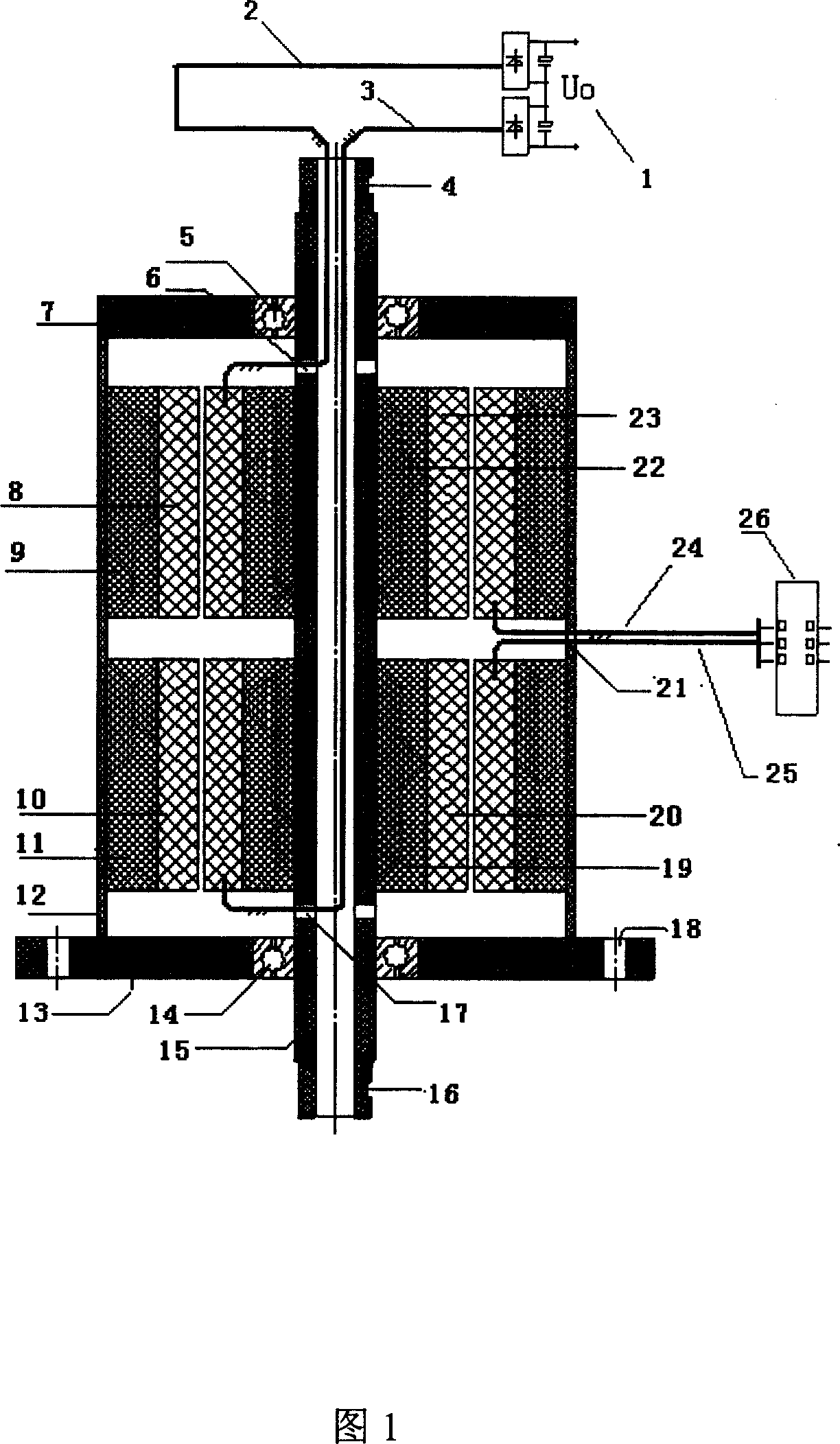

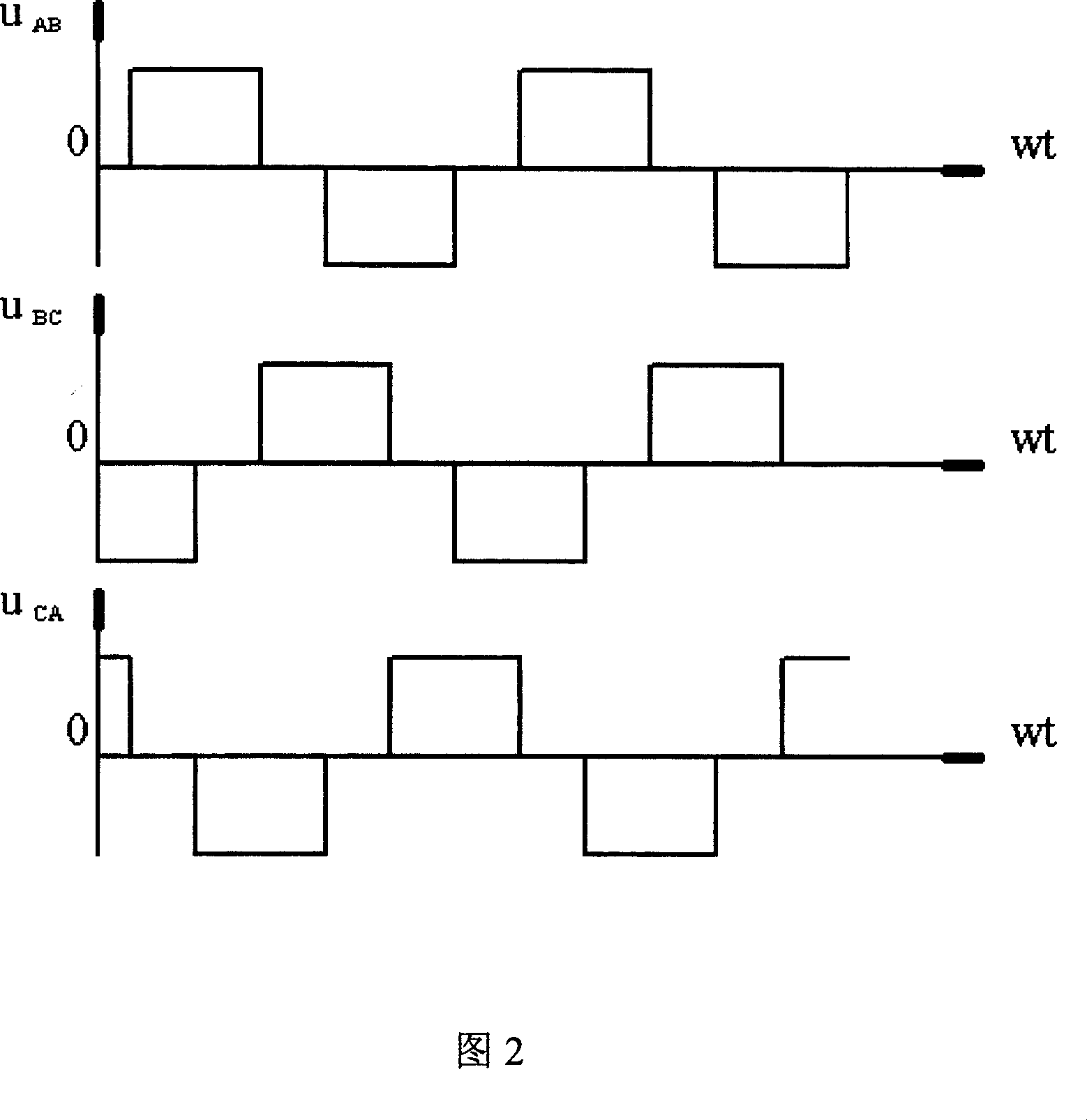

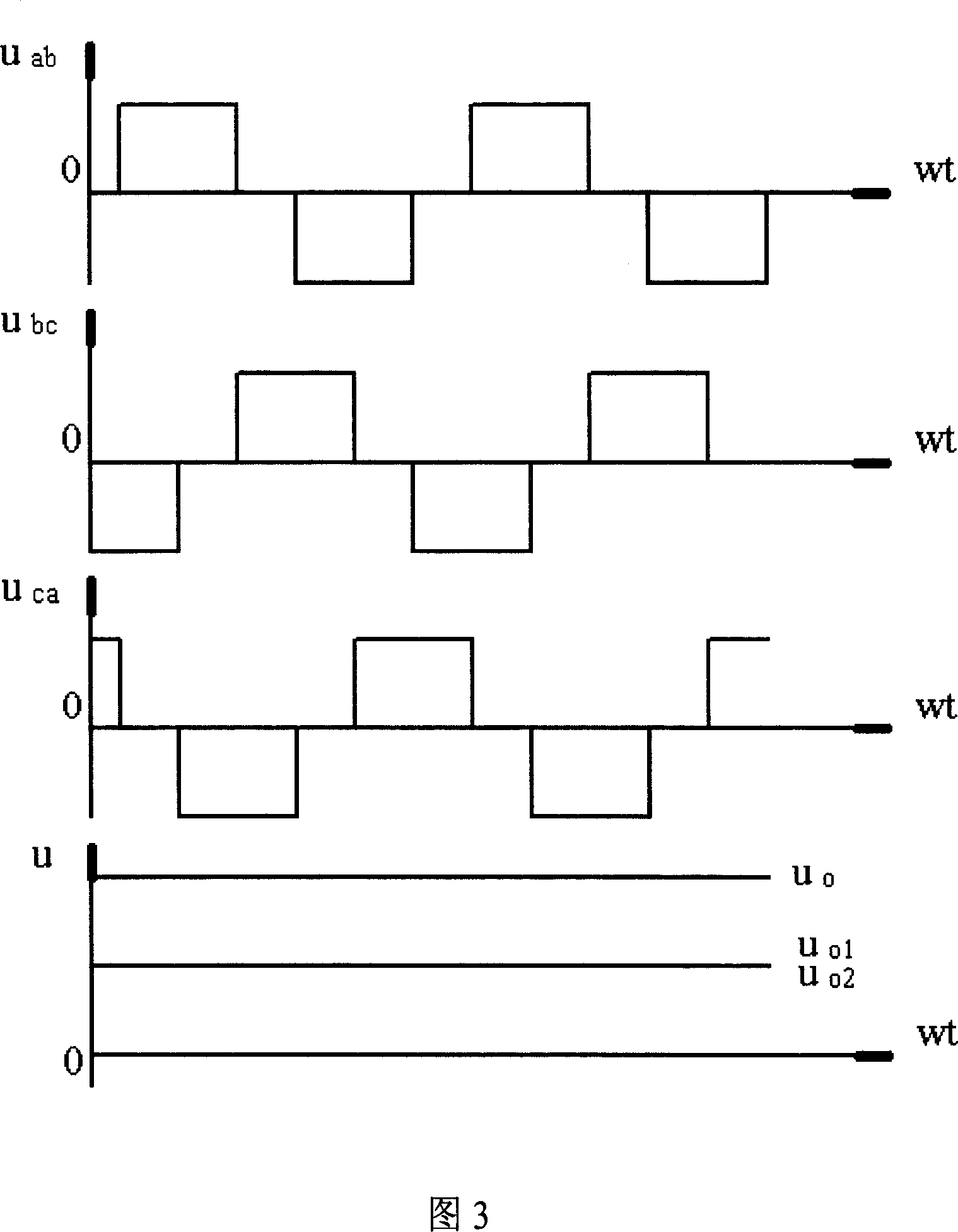

[0025] As shown in the figure, the present invention includes a casing, a rotating shaft, a stator, a rotor, an input power supply, and an output circuit. Both the stator and the rotor are embedded with three-phase windings. The stator and the rotor are divided into upper and lower sets and coaxially installed in the casing. With the alternating current of opposite phase sequence, the outputs of the two rotors are superimposed in series after passing through the rectifier circuit respectively.

[0026] In Fig. 1, the device has an upper end cover and a lower end cover, and bearings for fixing the rotor are installed on the cover; threading holes are opened on the inner walls at both ends of the rotating shaft for the three-phase lead wires of the rotor to pass through, between the upper and lower sets of stator and rotor There are also thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com