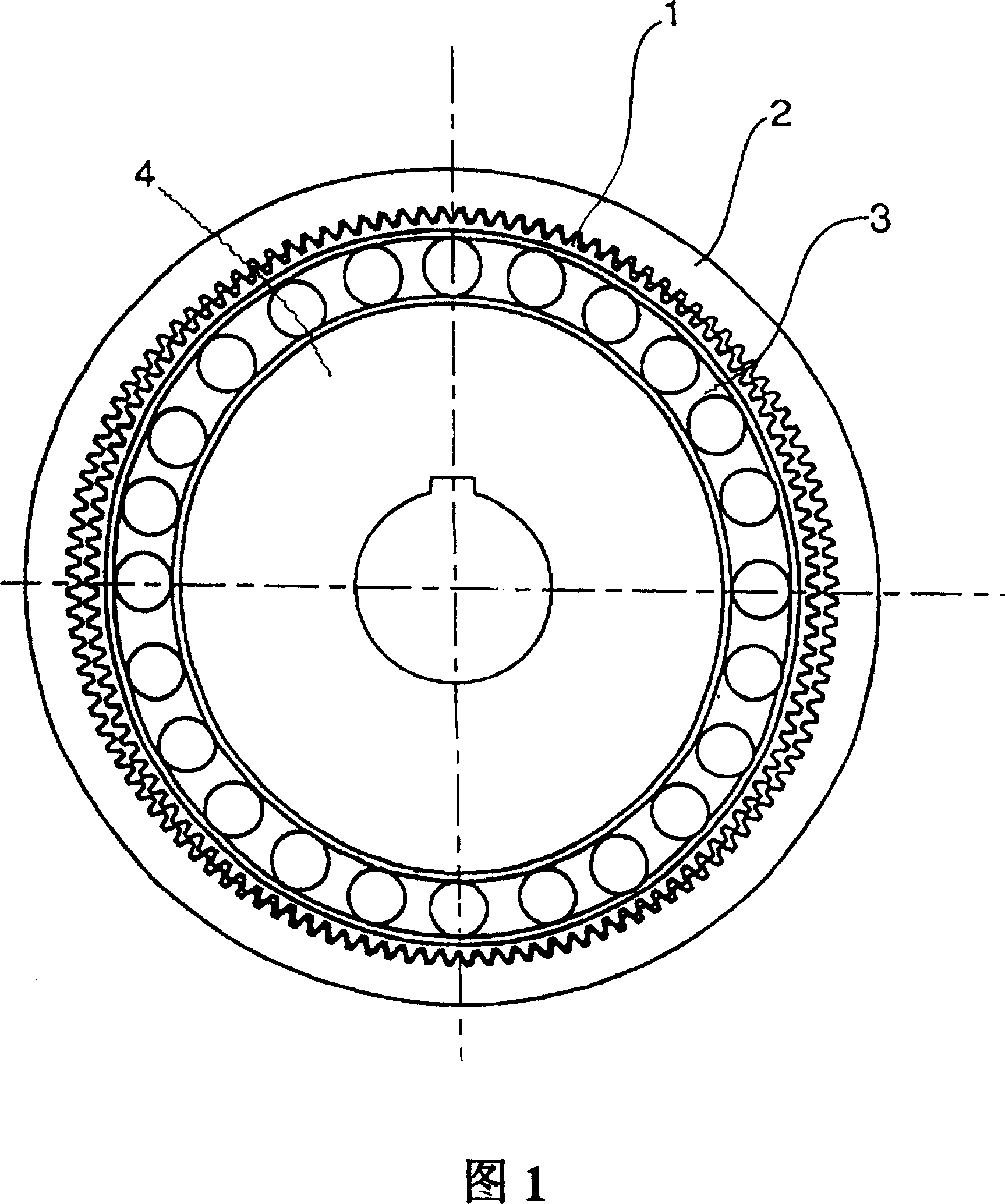

Three-dimensional harmonic wave gear with involute tooth outline

A technology of three-dimensional shape maintenance and harmonic transmission, which is applied to gear transmissions, transmissions, components with teeth, etc., can solve the problem of reducing the amplitude of flexspline involute tooth profile changes. It is not mentioned and cannot be applied. multiple situations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

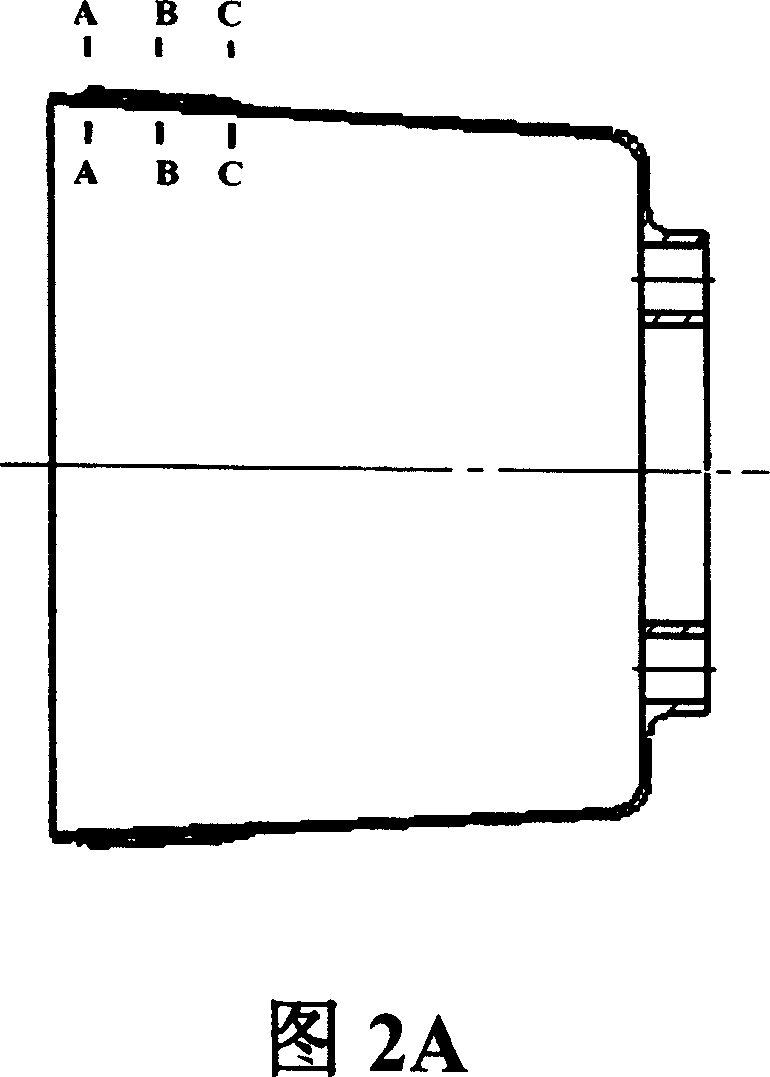

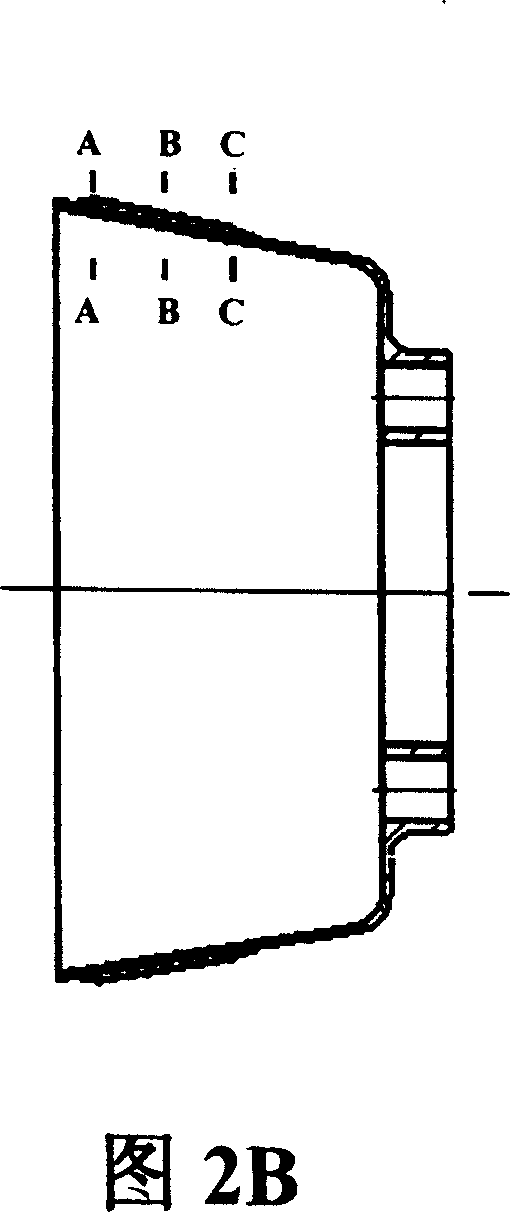

[0047] The invention adopts the method of directly calculating the gap between each pair of teeth of the flexible wheel and the rigid wheel meshing with each other when there is no load to design and calculate the tooth profile of the flexible wheel and the rigid wheel. This method is not only suitable for the situation when the flexspline and rigid gear adopt involute tooth profile, but also the situation when the flexspline and rigid gear adopt non-involute tooth profile, and it is suitable for any kind of cam profile. Happening. The following uses the involute tooth profile of the flexible wheel and the rigid wheel as an example to briefly explain this design calculation method.

[0048] Follow the following two principles in the design.

[0049] 1. The neutral layer of the flexspline is neither stretched nor shortened after deformation;

[0050] 2. The shape of the tooth profile remains unchanged after the flexspline is deformed, and the symmetry line of the tooth profile coin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com