Lightweight component for bearing elements of motor vehicles

A structural and lightweight technology, applied to household components, superstructures, vehicle components, etc., can solve problems such as limiting the number of ribs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

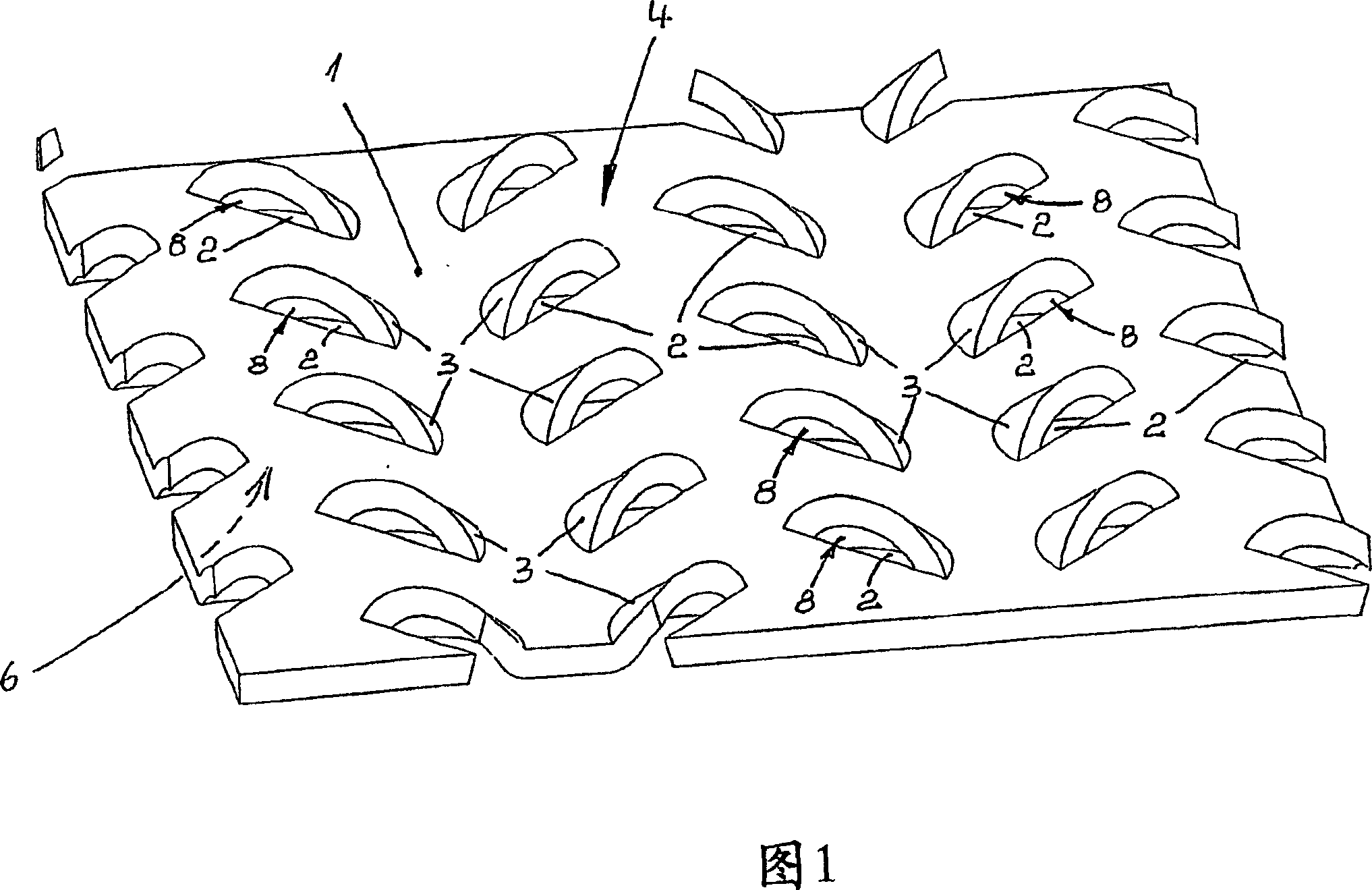

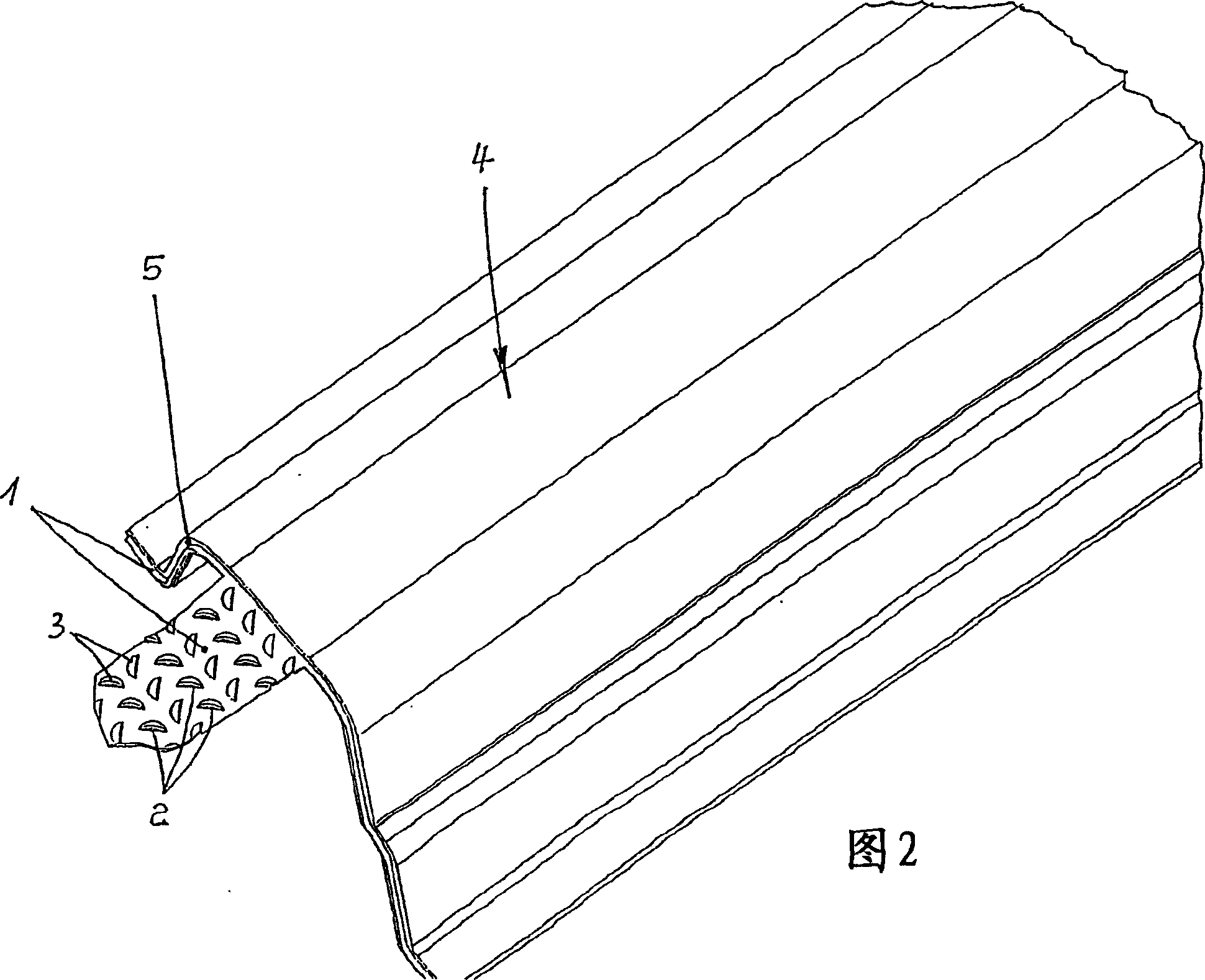

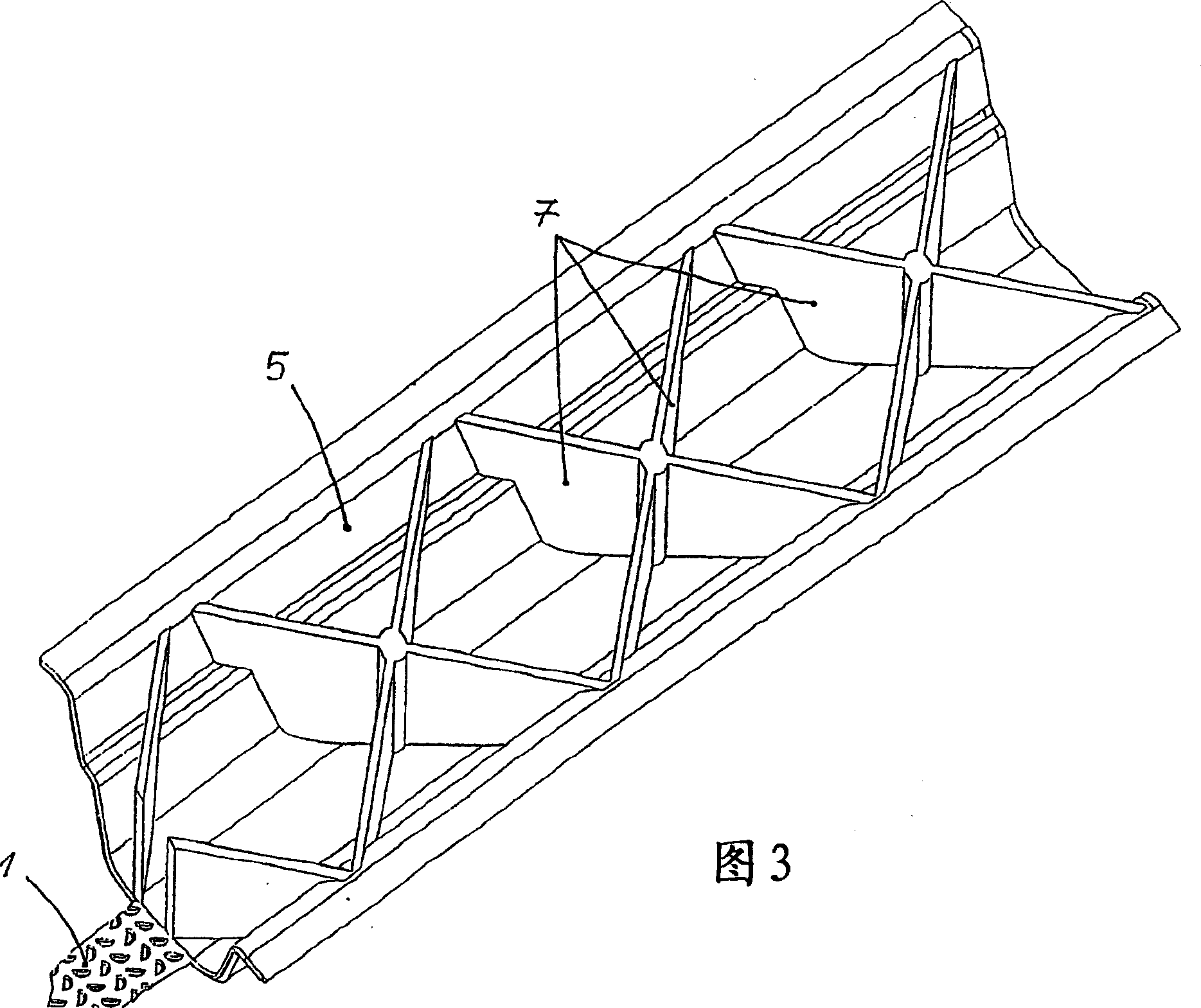

[0017] FIG. 1 shows in detail a part of a metal lining which has not yet been three-dimensionally deformed, which is a flat structure and is made of a steel sheet. Holes 2, ie through-holes, are machined in this steel sheet in a special manner, in such a way that the metal lining 1 has a sieve-like structure. The metal lining 1 resembles a kitchen cot and has a profiled outside, namely the pouring side 4, and a smooth inside 6 on which there are only through-hole openings.

[0018] Protruding from the outer casting side 4 are projections 3 punched out of the metal sheet of the metal lining 1 , which have approximately the shape of a quarter-shaped hollow sphere. As a result, the projection 3 has the shape of an open shell, wherein the half-shell opening 8 on the pouring side 4 forms the opening of the through-hole 2 . The opening planes of the holes 2 on the pouring side 4 are approximately perpendicular to the base surface of the metal backing 1 , wherein the planes of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com