Industrial robot path planning method and system based on pseudo-distance function

An industrial robot and path planning technology, applied in the field of robotics, can solve problems such as low RRT, inability to guarantee path quality, and large path differences, and achieve the effects of good path quality, excellent path, and fast convergence speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

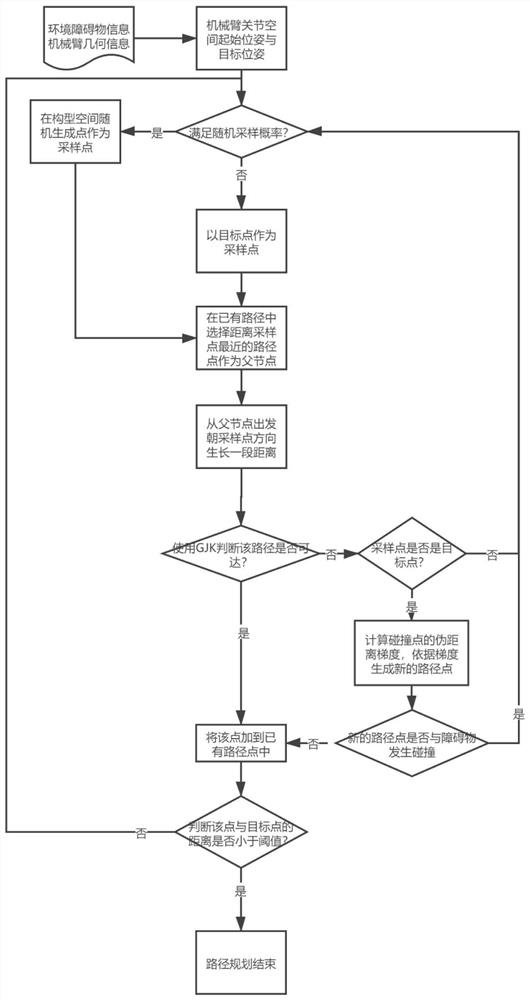

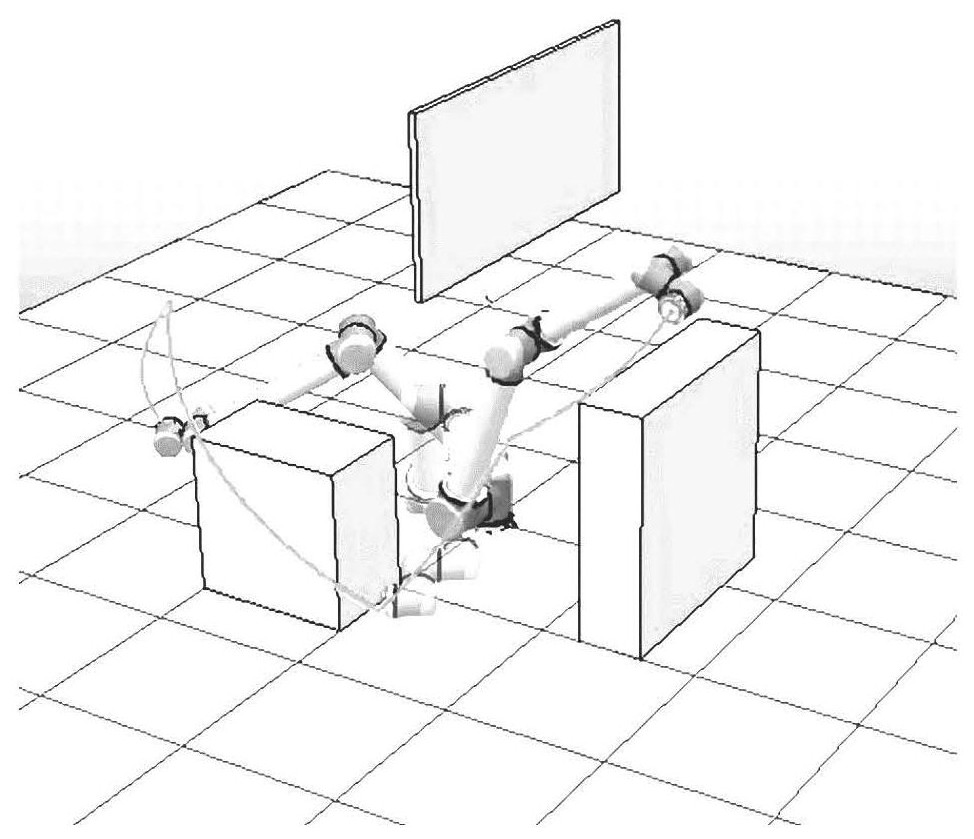

[0069] The object of the present invention is to provide a kind of fast, stable non-collision path generation method that is applicable to industrial manipulator, comprises the steps:

[0070] Step 1: Use a convex polyhedron to envelop obstacles and robotic arms;

[0071] Step 2: Input the starting point joint configuration θ star and the joint configuration θ of the target point goal ;

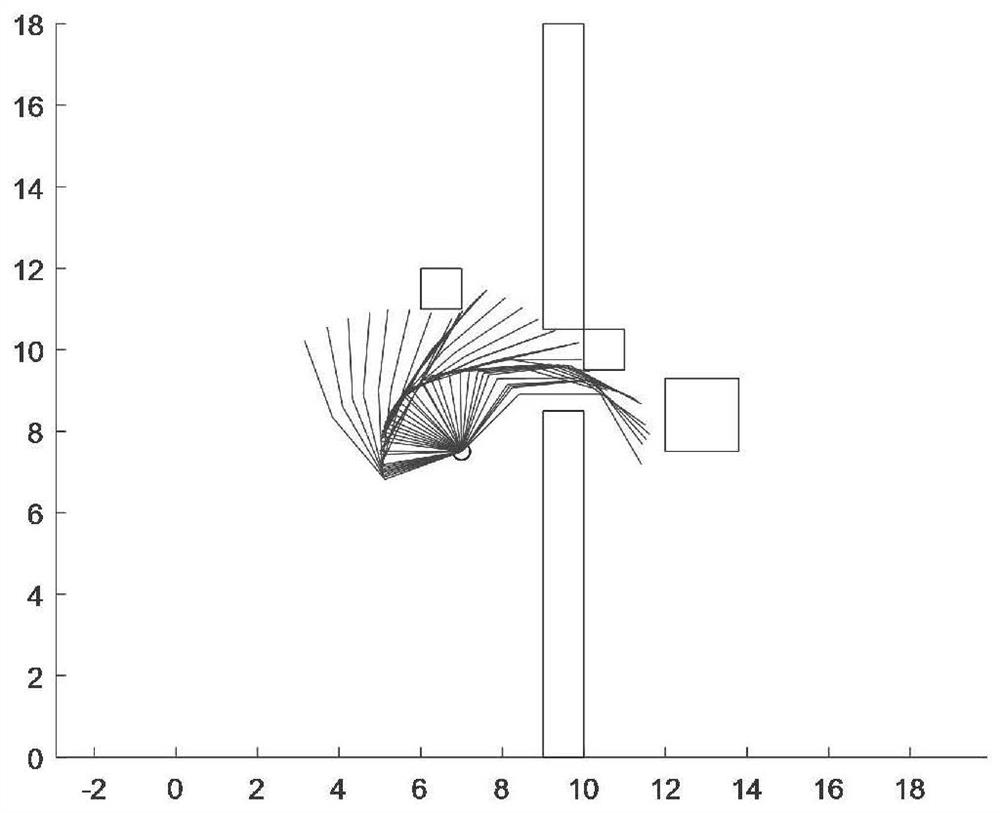

[0072] Step 3: Generate random points with a certain probability or use the target point as the sampling point θ sample , select the point closest to the sampling point among the existing path points as the parent node θ parent Grow a distance along the direction of the sampling point to generate a new path point θ new ;

[0073] Step 4: Discretize the path between the parent node and the new path point, and map the joint parameters of the joint space of the manipulator into the geometric shape of the workspace of the manipulator through the kinematic equation of the manipulator; use the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com