Process for microwave synthesis of rare earth compound nano rod

A technology of rare earth compound and microwave synthesis, applied in rare earth metal compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of long reaction time, high reaction temperature, multiple energy sources, etc., and achieve high photon quantum yield and stable chemical properties , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: prepare La 0.8 Ce 0.2 PO 4 Nano stave

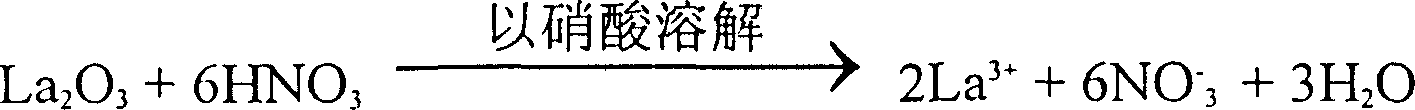

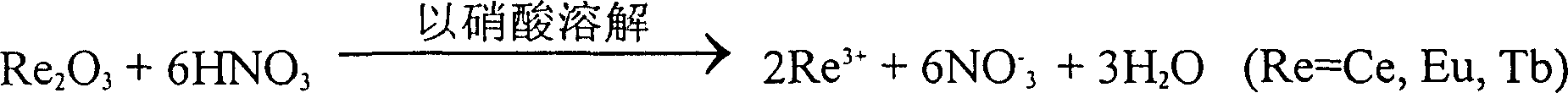

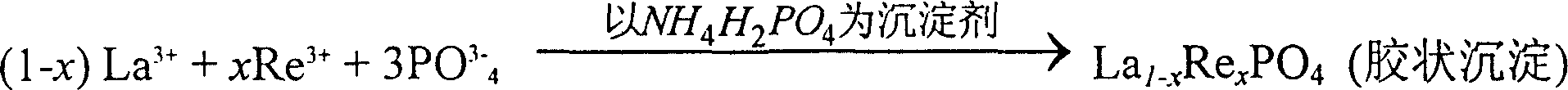

[0017] 0.456g of La 2 o 3 powder and 0.115g of Ce 2 o 3 Powder dissolved in 50mL 10% HNO 3 A mixed solution is formed in the solution, and in the mixed solution La 3+ Ion and Ce 3+ Ion molar ratio La 3+ : Ce 3+ =80:20. Then the pH value of the mixed solution was adjusted to 2.6 with ammonia water. Add 75mL of 0.05mol / L NH under electromagnetic stirring 4 h 2 PO 4 Aqueous solution produces a colloidal precipitate. Finally the jelly thing obtained is transferred to a 250ml round-bottomed flask and placed in a microwave oven, first leading to nitrogen for 30min, then microwave heating for 20min under nitrogen protection and reflux conditions, and the microwave heating power is 80% of maximum power (maximum power is 600W), after heating, continue to pass nitrogen until cooling to room temperature, the precipitated product is fully washed with centrifugation and deionized water, and dried under vacuum at 8...

Embodiment 2

[0018] Embodiment 2: prepare La 0.5 Ce 0.5 PO 4 Nano stave

[0019] 0.815g of La 2 o 3 powder and 0.820g of Ce 2 o 3 Powder dissolved in 35mL 20% HNO 3 A mixed solution is formed in the solution, and in the mixed solution La 3+ Ion and Ce 3+ The molar ratio of ions is La 3+ : Ce 3+ =50:50. Then use ammonia water to adjust the pH value of the mixed solution to 4.5, add 70ml of 0.15M NH under electromagnetic stirring 4 h 2 PO 4 , to generate a colloidal precipitate, transfer the obtained colloid to a 250ml round-bottomed flask and place it in a microwave oven, first pass nitrogen gas for 40 minutes, then microwave for 20 minutes under nitrogen protection and reflux conditions, and the microwave heating power is the maximum power 70% (maximum power is 600W), after heating, continue to pass nitrogen until cooling to room temperature, the precipitated product is fully washed with centrifugation and deionized water, and dried under vacuum at 80°C to obtain La 0.5 Ce ...

Embodiment 3

[0020] Embodiment 3: prepare La 0.95 Eu 0.05 PO 4 Nano stave

[0021] 0.542g of La 2 o 3 powder and 0.031g of Eu 2 o 3 Powder dissolved in 50mL 10% HNO 3 A mixed solution is formed in the solution, and in the mixed solution La 3+ and Eu 3+ The molar ratio of La 3+ :Eu 3+ =95:5. Then use ammonia water to adjust the pH value of the mixed solution to 2.9, add 75ml of 0.05M NH under electromagnetic stirring 4 h 2 PO4 aqueous solution, a colloidal precipitate is formed, and finally the obtained colloid is transferred to a 250ml round-bottomed flask and placed in a microwave oven, first passed nitrogen for 30 minutes, then microwaved for 40 minutes under nitrogen protection and reflux conditions, and the microwave heating power is the maximum 60% of the power (maximum power is 600W), after heating, continue to pass nitrogen to cool to room temperature, the precipitated product is fully washed with centrifugation and deionized water, and dried under vacuum at 80°C to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com