Coloured liquid crystal display device

A liquid crystal display device, color technology, applied in transistors, static indicators, optics, etc., can solve the problems of increasing the complexity of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

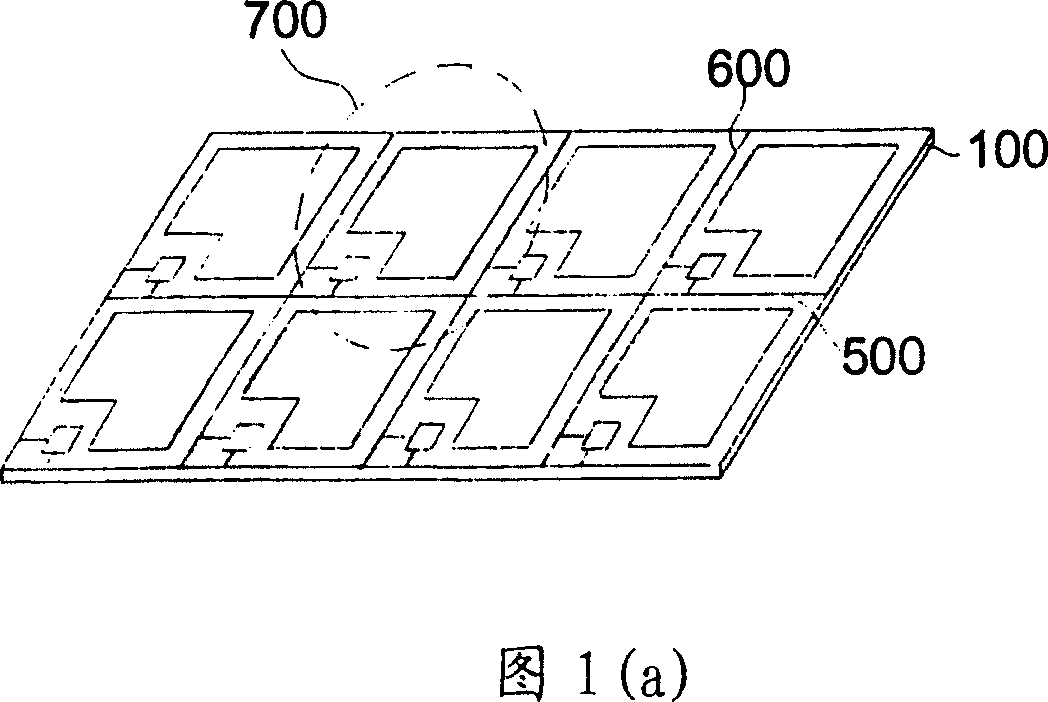

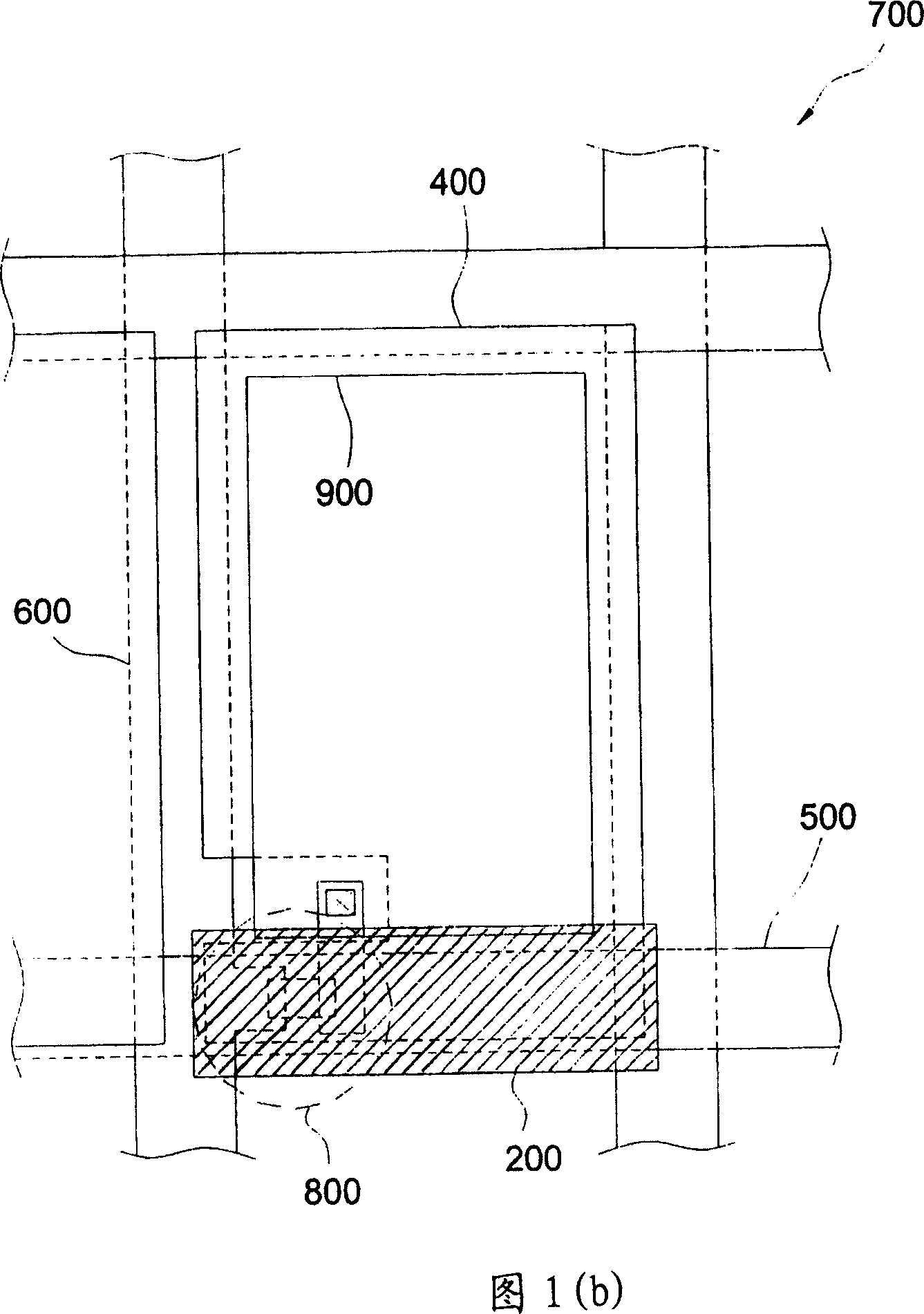

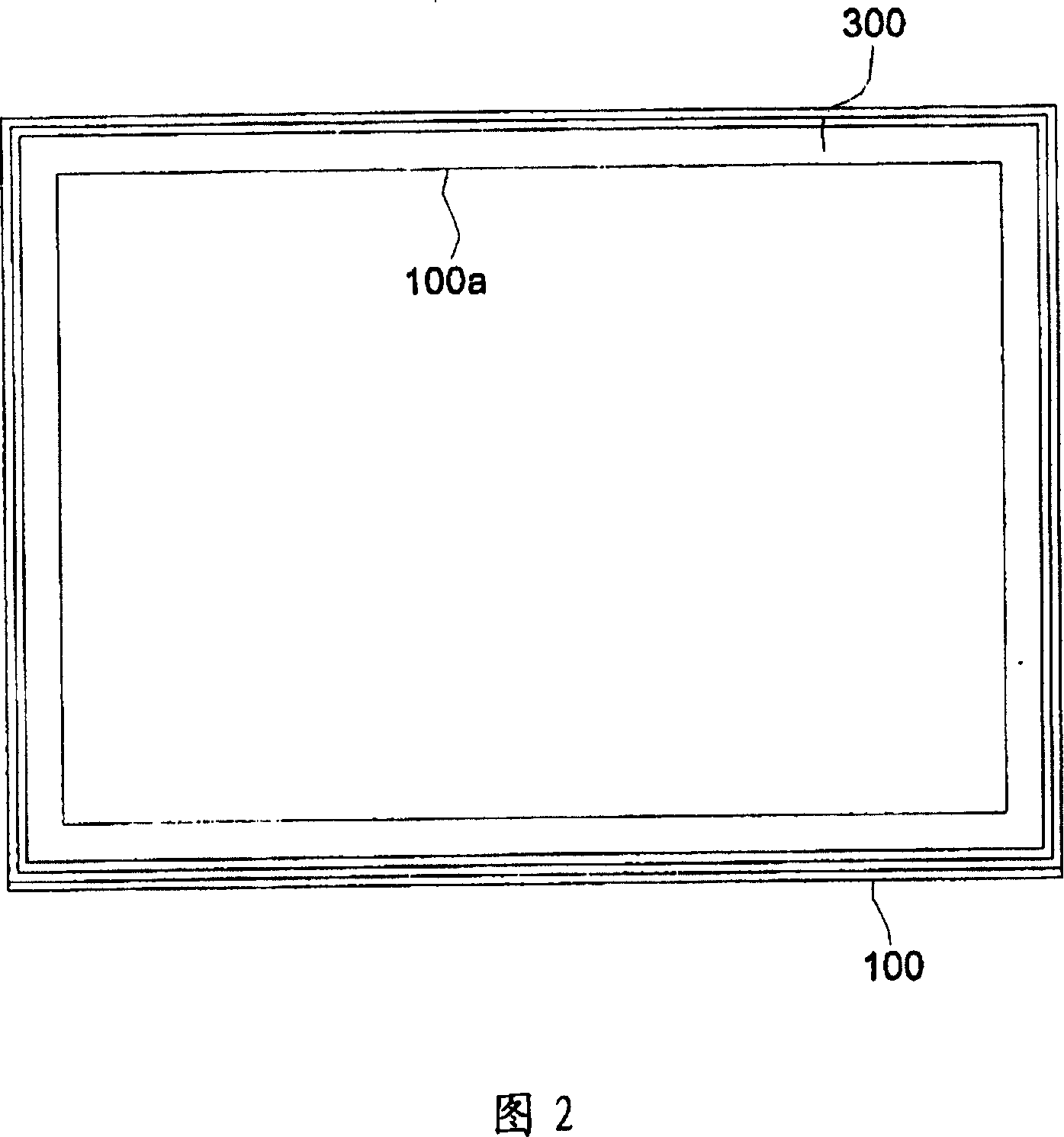

[0019] The present invention provides a color liquid crystal display device. As shown in FIG. 4 , the device includes an array circuit substrate 100, and a light-shielding layer 200 is formed on the array circuit substrate 100. The surrounding of the light-shielding layer 200 includes a frame layer 300 for use in To prevent light leakage around the array circuit substrate 100 , a color filter layer 400 is formed on the array circuit substrate 100 and the light shielding layer 200 . The main feature of the liquid crystal display device is that the color filter layer 400 is extended to cover the frame layer 300 to reduce the difference between the liquid crystal region 1 and the liquid crystal region 2 . Covering the red, blue and green color filter layers on the frame layer can add a dielectric layer to reduce the circuit load, and the film thickness of the color filter layers can be adjusted flexibly. In this way, without affecting the gap between the upper and lower boards, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com