Process and system for manufacturing prefabricated electrical conductors

An electrical conductor and process technology, applied in the field of prefabricated electrical conductors, can solve the problems of time-consuming equipment, labor, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

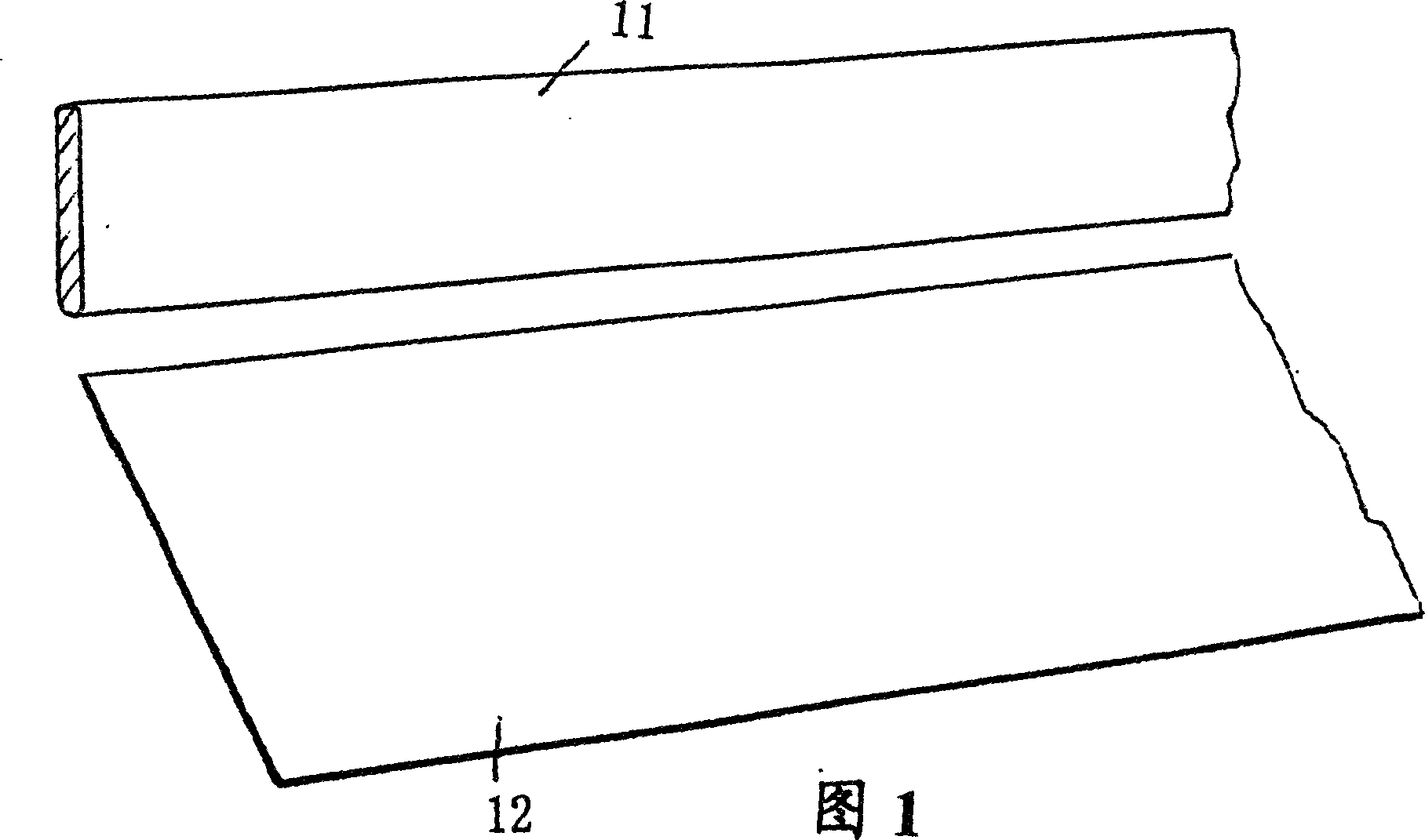

[0021] In said drawings, FIG. 1 shows a conductor strip 11 and an insulating sheath 12 in an initial state. The conductor strips are generally straight and can be of various lengths and cross-sections, the insulation sheath is unrolled and pre-cut to dimensions corresponding to the dimensions of the conductor strips.

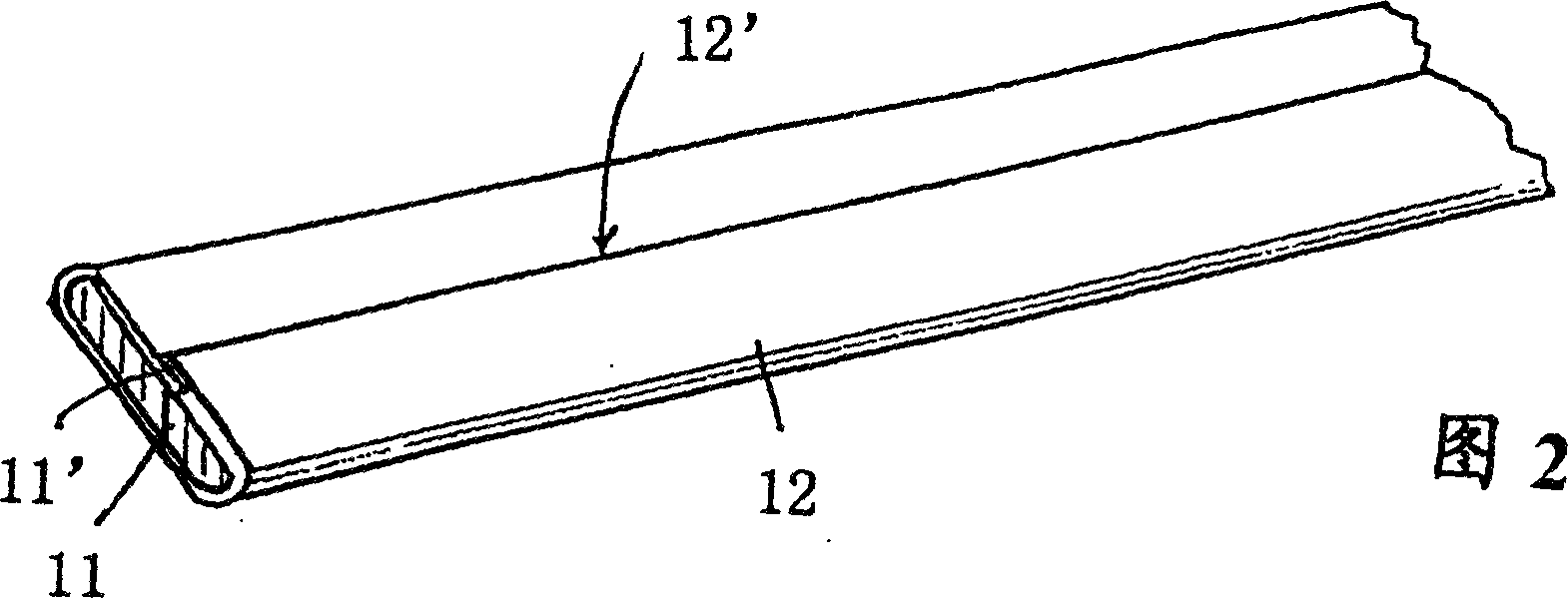

[0022] According to this process, the sheath 12 is loaded onto a generally channel-shaped shaped support, and the conductor strip 11 is placed on the sheath and then fitted into the channel so that the sheath is folded tightly around it following the contour of the conductor strip -figure 2. A portion 11' of the conductor strip and an edge 12' of the sheath are pre-applied with a layer of adhesive or glue that allows the two to Interacting parts - conductor bar / sheath connection.

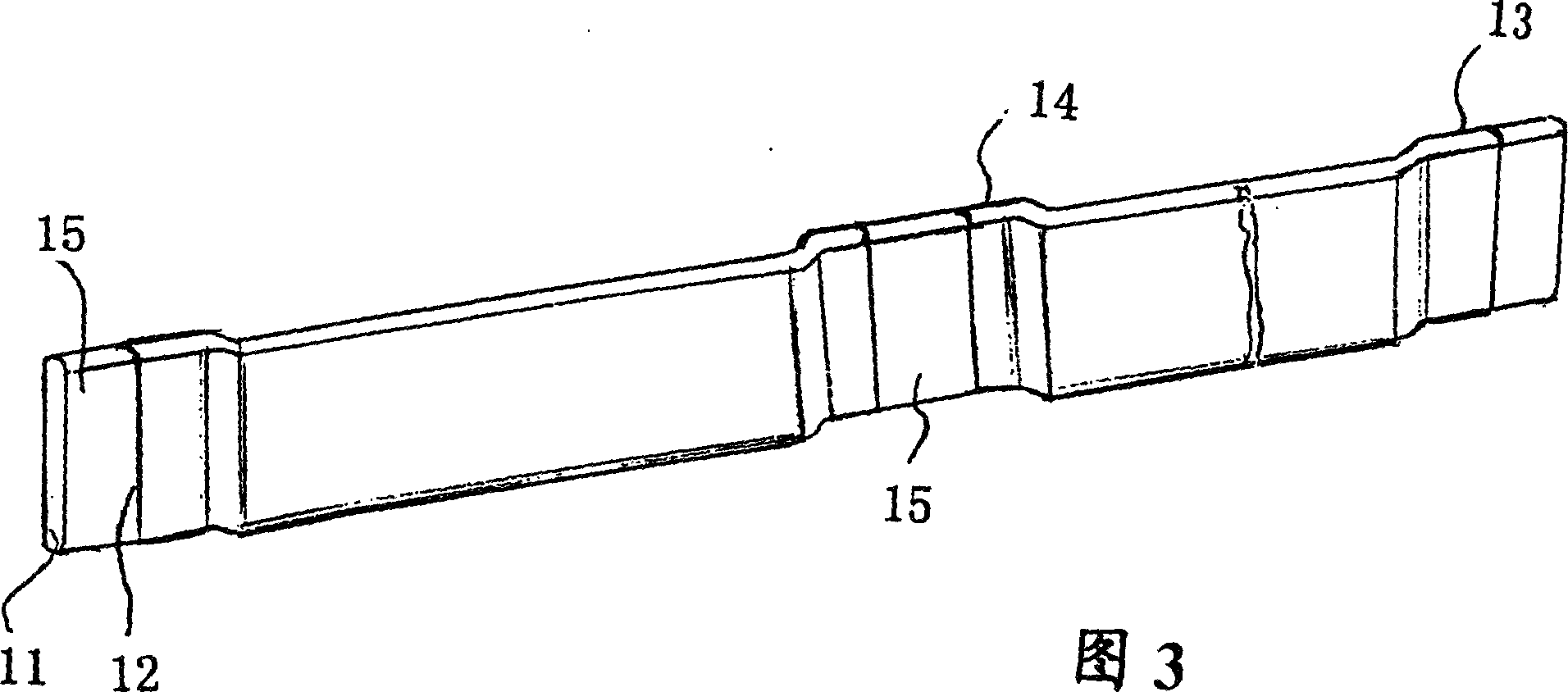

[0023] The conductor strip thus nested and thus insulated is then picked up with said channel-shaped support, and then conveyed to the bending station where the opposite end 13 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com