Self-operated full trailer

A trailer and car body technology, which is applied in the field of trailers, can solve the problems of heavy load, no literature reports on the same or similar topics, time-consuming and labor-intensive problems, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

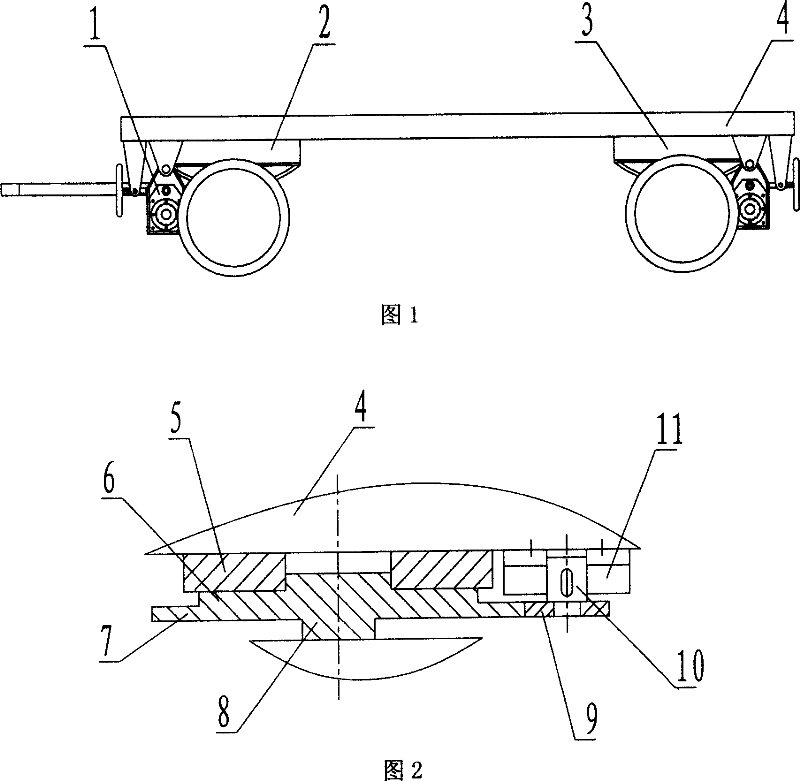

[0016] As shown in FIG. 1 , the present invention includes: a wheel drive mechanism 1 , a front steering suspension 2 , a rear steering suspension 3 and a vehicle body 4 . The wheel driving mechanism 1 is located on the car body 4, and there are four sets of such mechanisms, each of which drives a wheel. The front steering suspension 2 and the rear steering suspension 3 are connected to the vehicle body 4 .

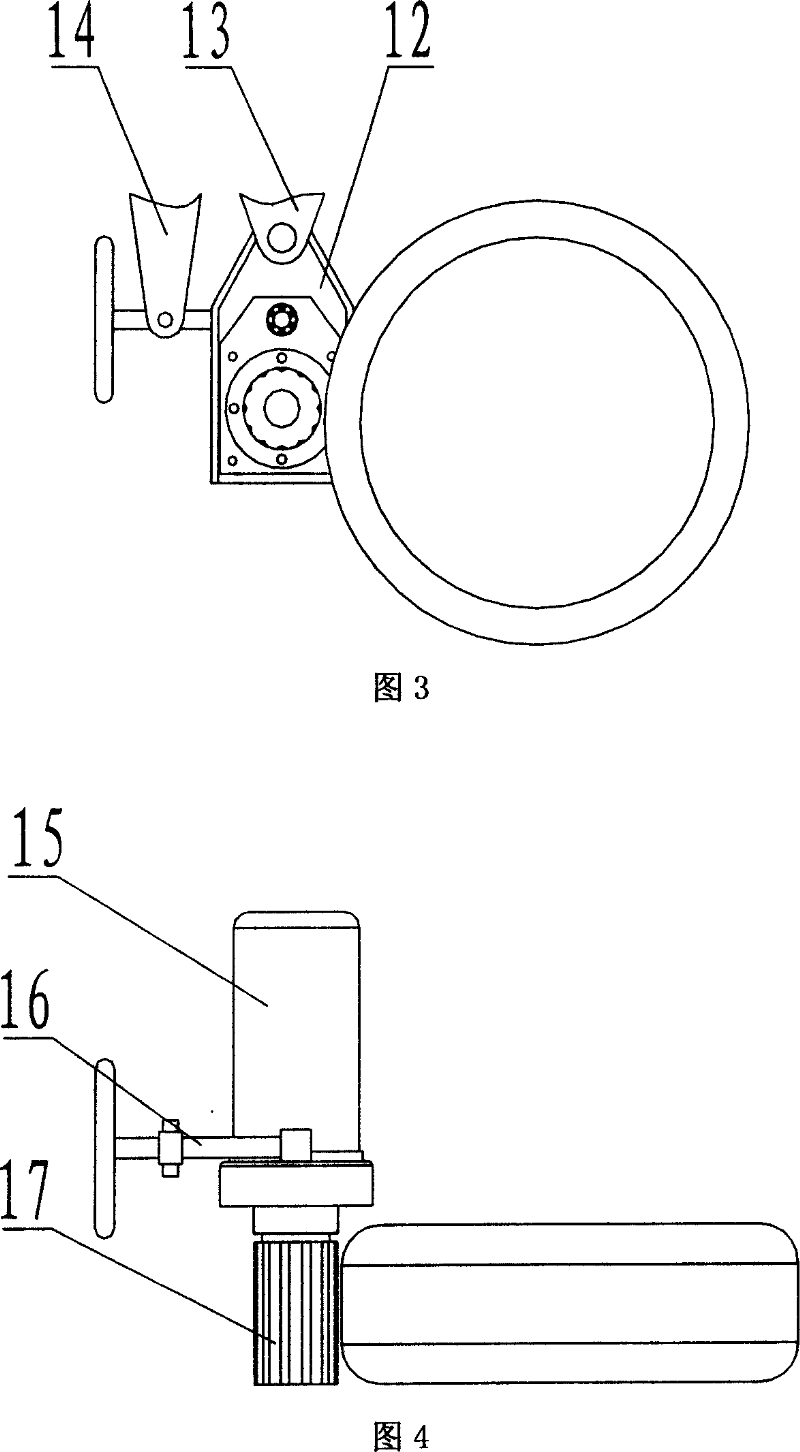

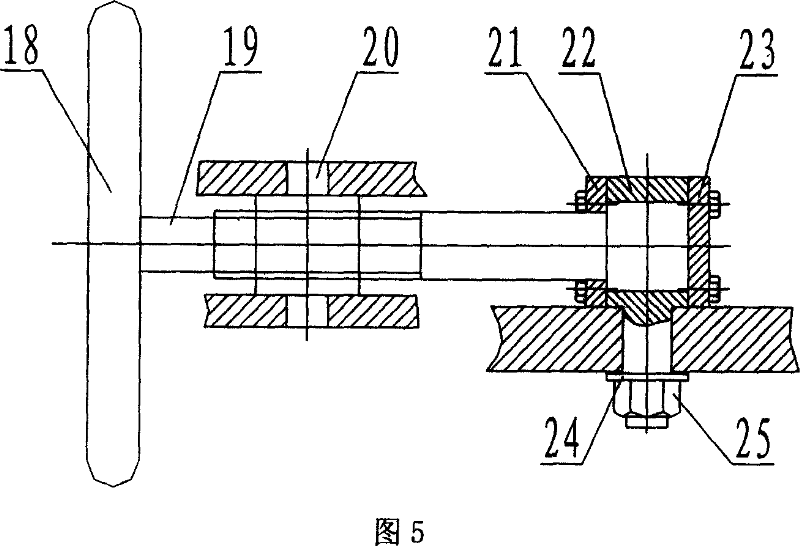

[0017] As shown in Figure 2, the structure of the front steering suspension 2 and the rear steering suspension 3 is exactly the same, including: a car body turntable 5, a suspension turntable 6, a large gear 7, a rotating shaft 8, a pinion 9, and a pinion shaft 10 , Clutch 11. The car body turntable 5 is connected with the car body 4, the suspension turntable 6 is connected with the front steering suspension 2 or the rear steering suspension 3, the car body turntable 5 and the suspension turntable 6 are connected by a sliding pair, and the rotation shaft 8 is used to ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com