Radiation expanding type make-up drum

A technology for laminating drums and drum blocks, which is applied to tires, household appliances, and other household appliances. It can solve the problems of uneven tire embryo forming quality, large sliding friction resistance, and low production efficiency, so as to achieve easy maintenance. Improvement of molding quality and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

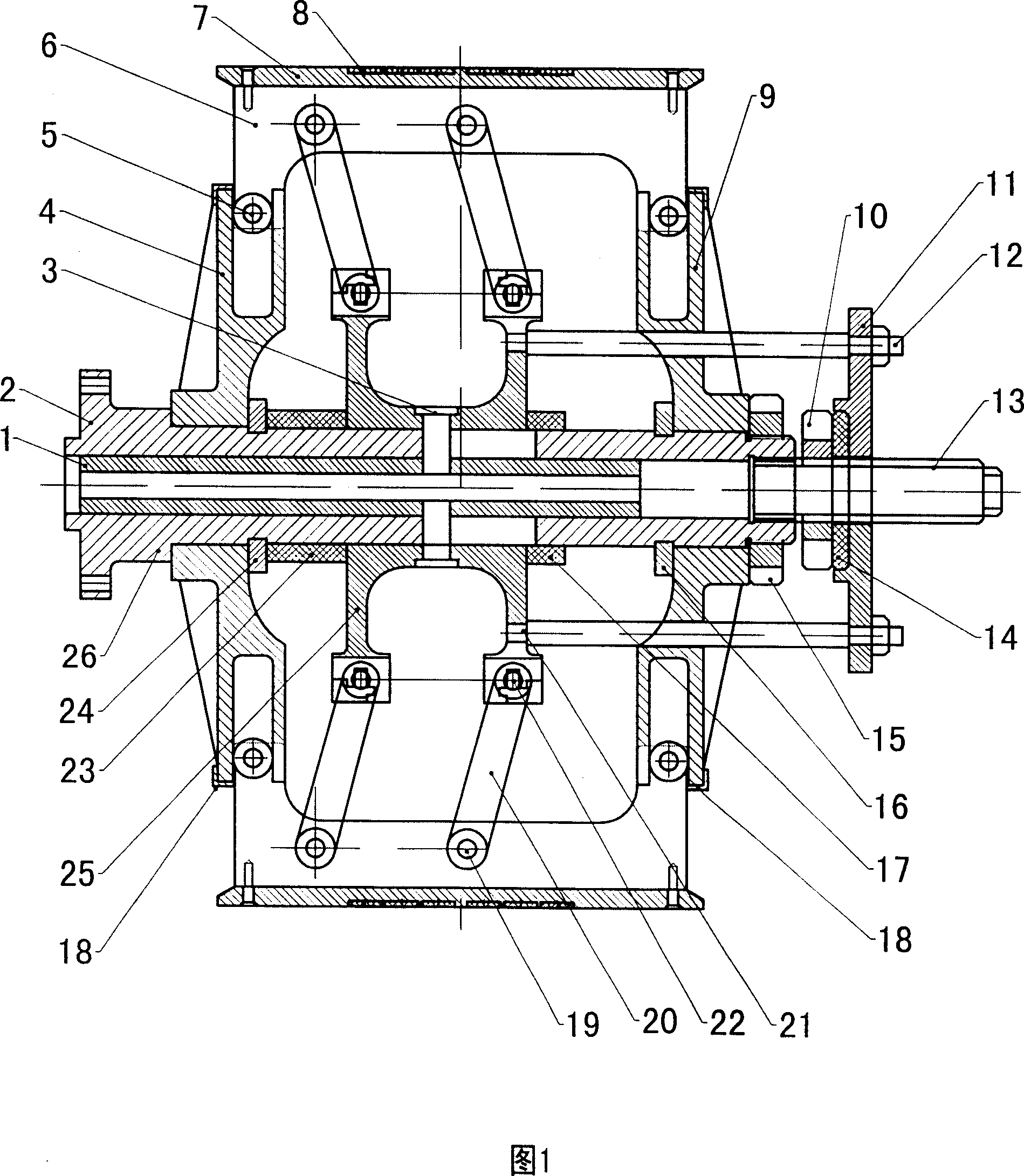

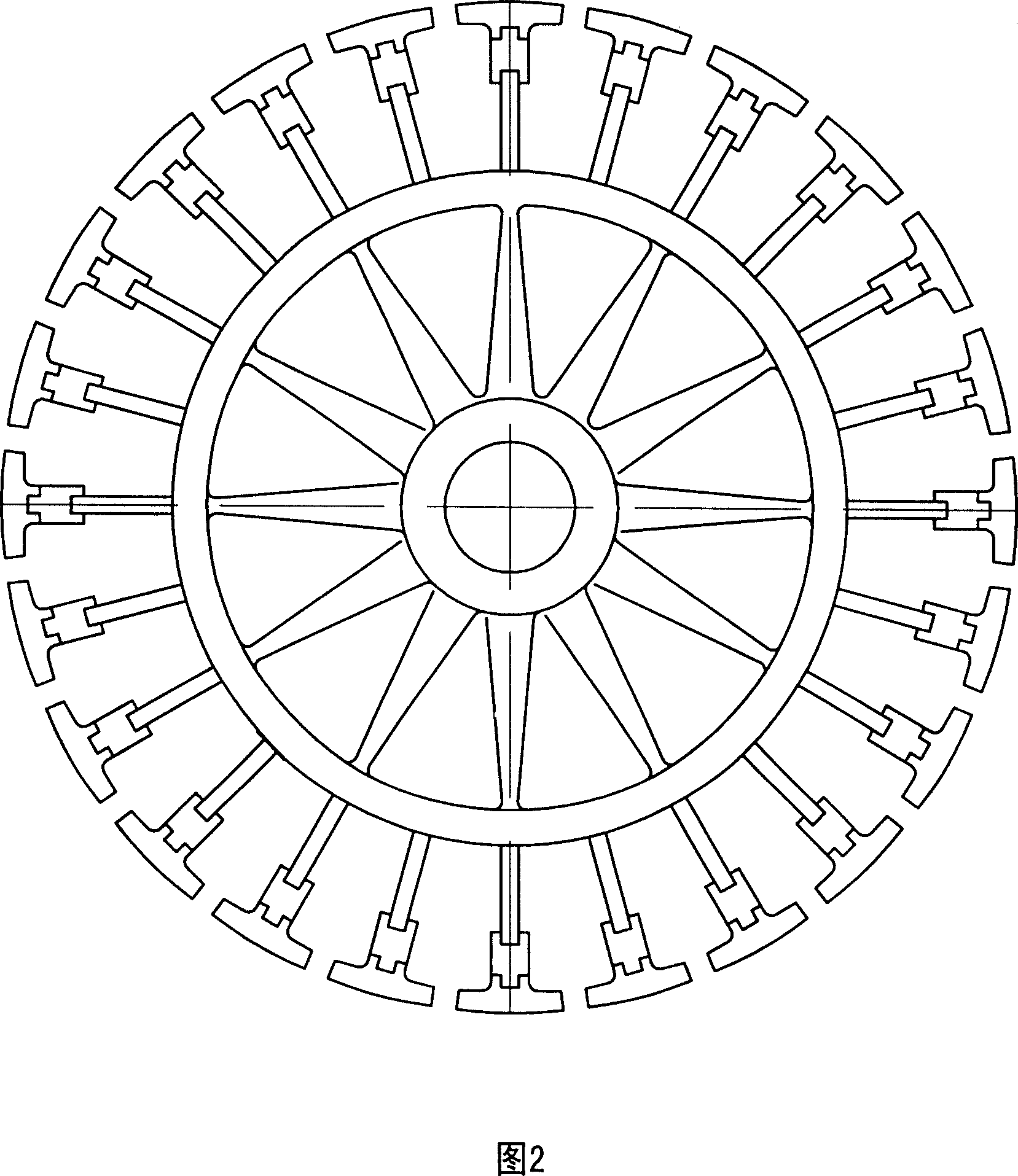

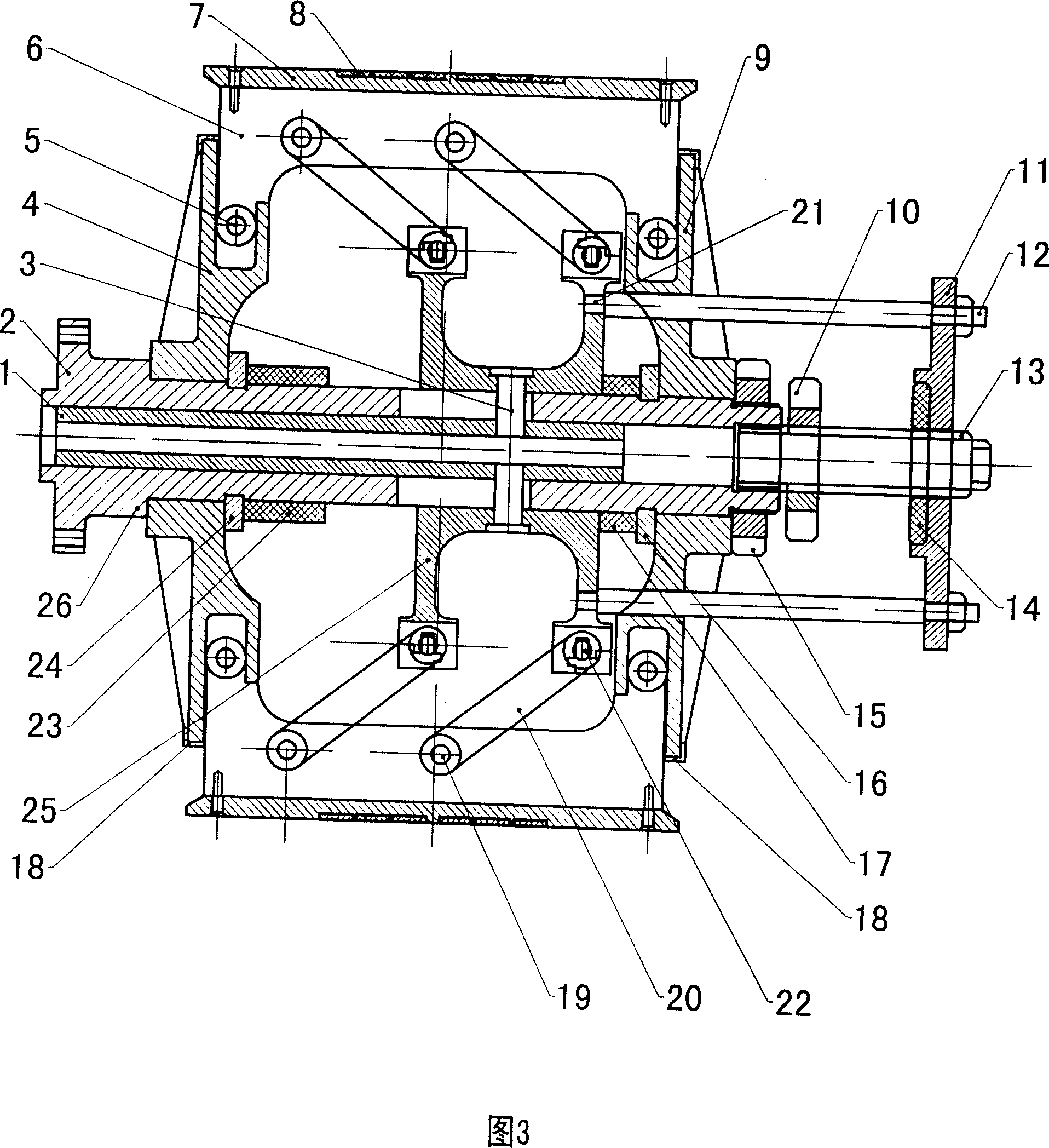

[0022] With reference to Fig. 1, Fig. 2, present embodiment is mainly by main shaft 2, push rod 1, connecting rod seat 25, connecting rod 20, slide block 6, bearing 5, front guide seat 4, rear guide seat 9, front retaining ring 23, Rear retaining ring 17, main shaft nut 15, front snap ring 24, rear snap ring 16 etc. are composed of, slide block 6 has twenty-four pieces, each of which is equipped with drum block 7, and drum block 7 is equipped with six magnetic blocks inside 8. The push rod 1 is connected with the driving cylinder of the molding machine, the front guide seat 4 is fixedly fitted on the front end of the main shaft 2 through the front snap ring 24 and the shaft shoulder 26, and the rear guide seat 9 is fixedly fitted on the main shaft 2 through the rear snap ring 16 and the main shaft nut 15 At the rear end, a dust cover 18 is arranged on the outer edges of the front guide seat 4 and the rear guide seat 9 respectively. The purpose of the dust cover 18 is to prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com