Seepage preventing construction structure and method

A technology of anti-seepage layer and consolidation layer, applied in basic structure engineering, water conservancy engineering, marine engineering and other directions, can solve the problems of easy breakage, lack of anti-seepage effect, poor impact resistance, etc., and achieve strong anti-deformation ability. , Excellent anti-seepage effect, and the effect of improving bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

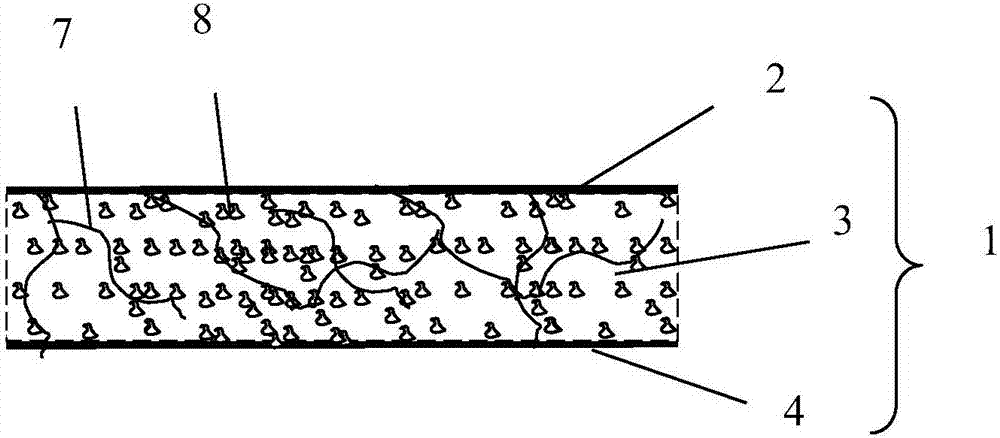

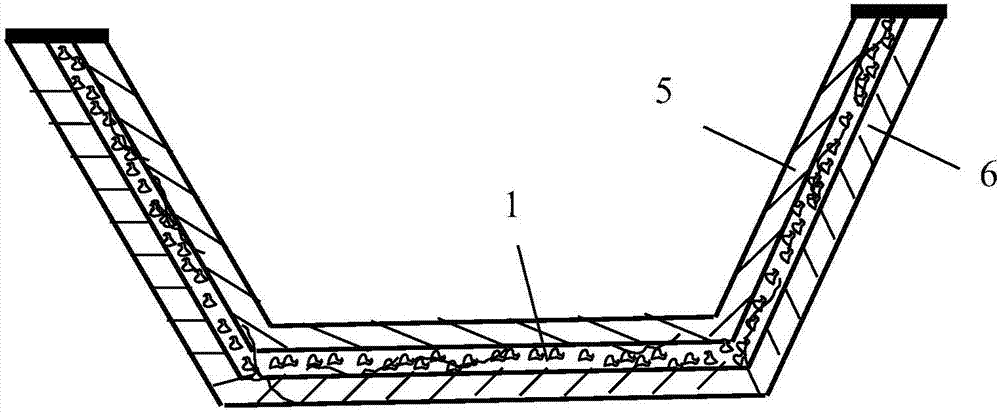

[0032] see Figure 1-Figure 2 As shown, the present invention provides a kind of anti-seepage construction structure, and this anti-seepage construction structure comprises soil foundation 6, waterproof layer 1 and surface covering soil layer 5 that are arranged sequentially from bottom to top, so that the anti-seepage layer can be built in situ, and utilize The local soil reduces the construction cost, in which the waterproof layer 1 includes the first anti-seepage layer 4, the soil consolidation layer 3 and the second anti-seepage layer 2 arranged in sequence from bottom to top, and adopts a three-layer impermeable structure, thereby greatly improving the anti-seepage effect, the permeability coefficient is less than 10 -10 cm / s; wherein the first anti-seepage layer 4 and the second anti-seepage layer 2 are formed by the soil consolidation of spraying EVA emulsion and / or polyurethane emulsion, and the spraying of EVA emulsion and polyurethane emulsion naturally penetrates in...

Embodiment 2

[0038] The soil foundation 6, the waterproof layer 1 and the surface covering layer 5 arranged in sequence from bottom to top, wherein the waterproof layer 1 includes the first anti-seepage layer 4, the soil consolidation layer 3 and the second anti-seepage layer 2 arranged in sequence from bottom to top, Wherein the first anti-seepage layer 4 is made of geotextile and / or asphalt laid on the soil foundation, and the second anti-seepage layer 2 is made of geotextile and / or asphalt laid on the soil consolidation layer, laying Geotextiles and / or asphalt are used as the anti-seepage layer, which is easy to lay and low in cost.

[0039] Preferably, the anti-seepage geotextile is sold by Suqian Jiafa Geotechnical Material Manufacturing Co., Ltd., and the mass per unit area is 800g / m 2 , film thickness 0.6mm.

Embodiment 3

[0041] This embodiment is a further improvement of Embodiment 1 and Embodiment 2. Wherein the soil consolidation layer 3 is formed by mixing and solidifying bentonite, fiber material, soil and water, wherein bentonite has the advantages of large water absorption expansion rate, fast expansion speed, aging resistance, corrosion resistance, etc., so that the soil consolidation layer is resistant to Good impact resistance and deformation resistance, compressive strength greater than 20MPa; wherein the soil consolidation layer 3 is made of bentonite, fiber material, soil and water mixing and solidification, wherein the fiber material is carbon steel fiber, stainless steel fiber, alkali-resistant One or more of glass fiber, carbon fiber, nylon fiber, aramid fiber, basalt fiber, PVA fiber, EVA fiber, wherein the fiber material has a diameter of 1-1000 μm and a length of 3-30 mm.

[0042] Preferably, the fiber material is PVA fiber; most preferably, the PVA fiber sold by Sinopec Sich...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com