Packaging structure of optical sensing chip and producing method thereof

A technology of packaging structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as affecting the light sensing effect and increasing the manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

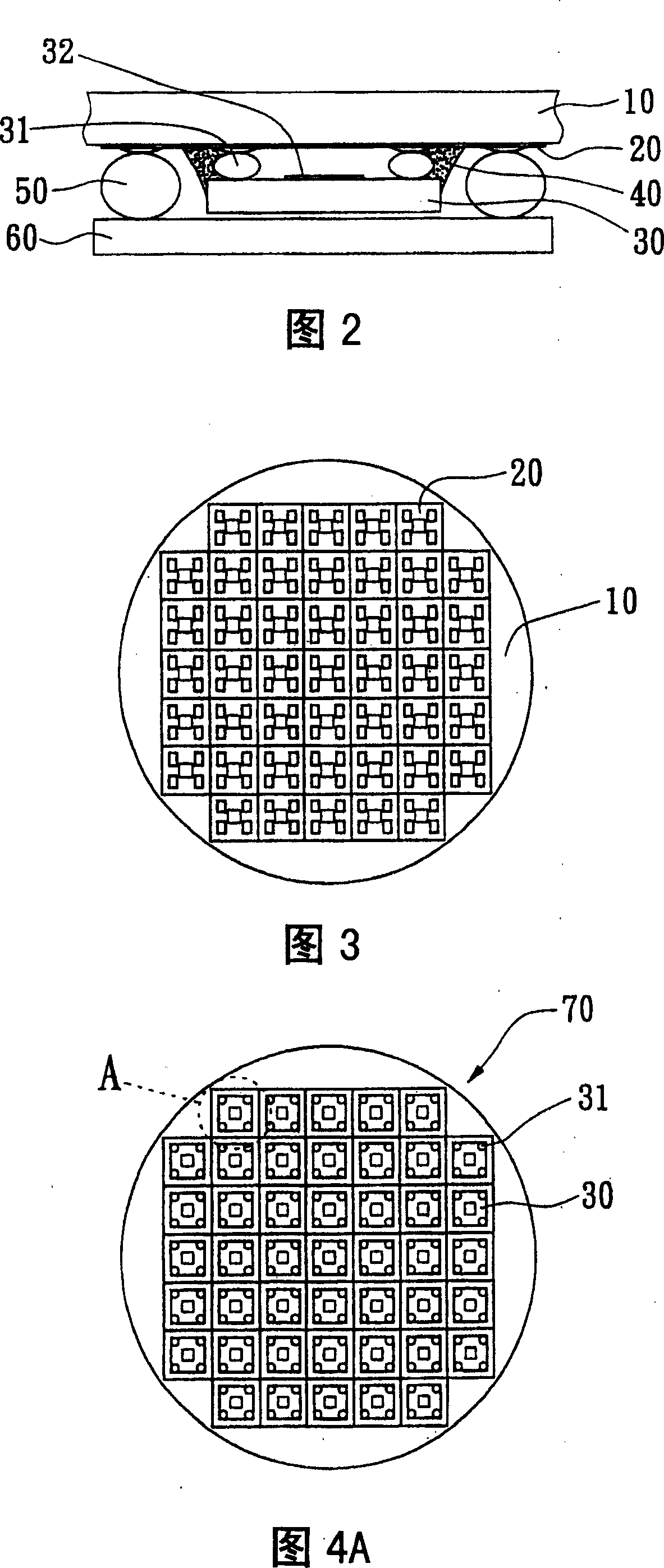

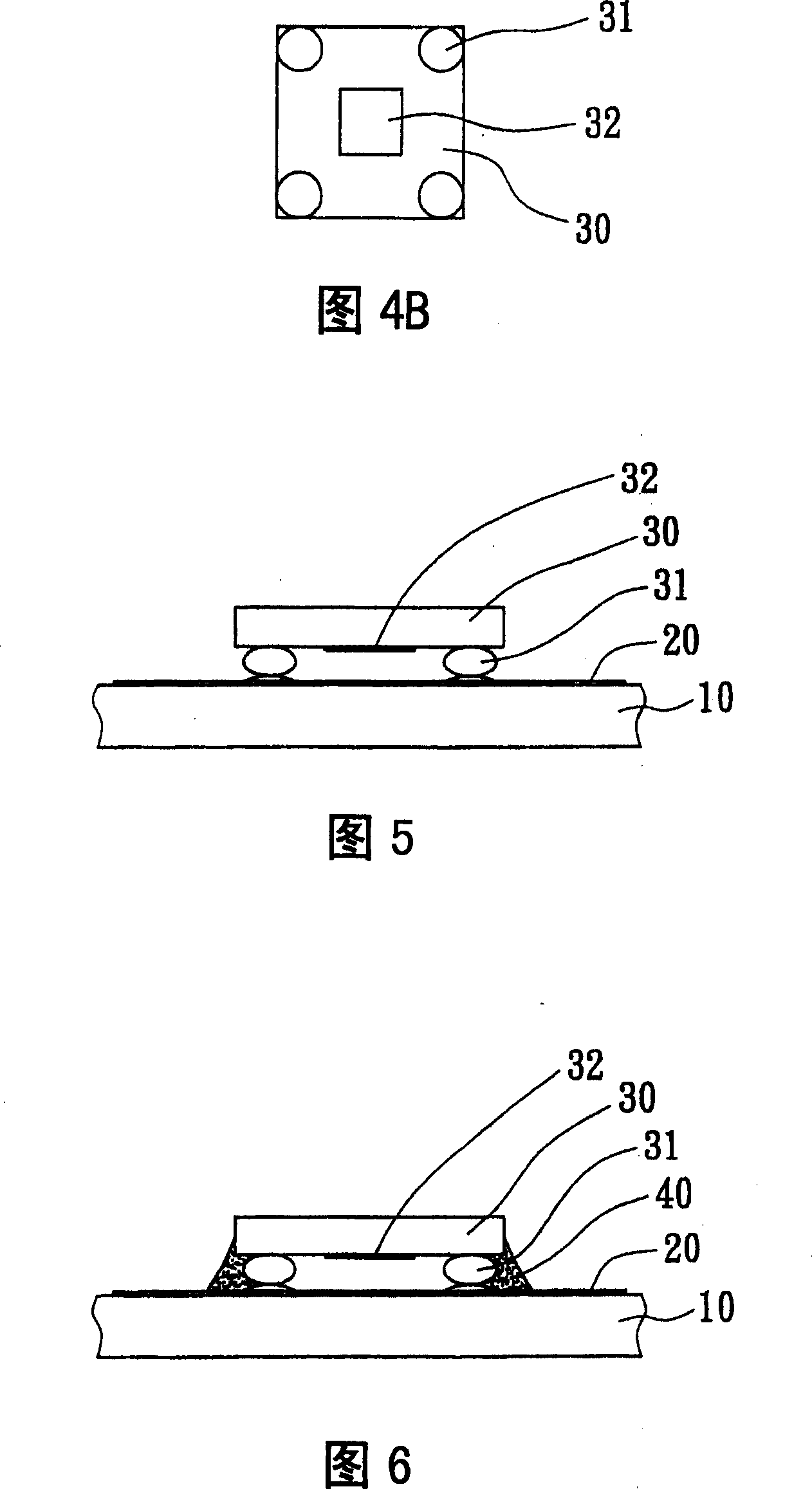

[0043] Please refer to FIG. 2, the present invention is a package structure of a photosensitive chip, which includes a light-transmissive substrate 10 and a printed circuit trace layer 20 attached to one side of the light-transmissive substrate 10, and makes the photosensitive chip The electrical connection portion 31 of 30 is electrically connected to the printed circuit trace layer 20, and the electrical connection portion 31 on the photosensitive chip 30 is located on the same side as the photosensitive area 32, and a protective glue 40 is adhered to the photosensitive chip 30 and On the transparent substrate 10, the photosensitive chip 30 is sealed on the transparent substrate 10, and a plurality of electrical connection bumps 50 are formed on the periphery of the photosensitive chip 30 on the printed circuit trace layer 20 to electrically connect on the printed circuit board 60 .

[0044] Please refer to FIG. 3 , where a transparent substrate 10 is firstly provided, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com