Heat transfer image recording composite sheet

A technology for image recording and composite sheets, applied in temperature recording methods, printing, printing devices, etc., can solve problems such as unsatisfactory quality of thermal transfer recording sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0113] There is no limitation on the preparation method of the hollow particles. The hollow particles may be selected from those mentioned below.

[0114] (i) expanded hollow particles prepared by thermally foaming particles comprising a thermoplastic polymer material and a thermally expandable substance mixed into the thermoplastic polymer material;

[0115] (ii) A microcapsule obtained by forming precursor microcapsules, each precursor microcapsule comprising a core portion consisting of a volatile liquid and a shell portion comprising a thermoplastic polymer material, the shell portion The volatile liquid is evaporated from the precursor microcapsules to form microcapsules each having a hollow core surrounded and closed by a shell by surrounding the core part by the microcapsule-polymerization method.

[0116] The hollow particles can also be produced by first forming a non-foamed adhesive layer comprising non-foamed particles formed by mixing a thermoplastic resin with a ...

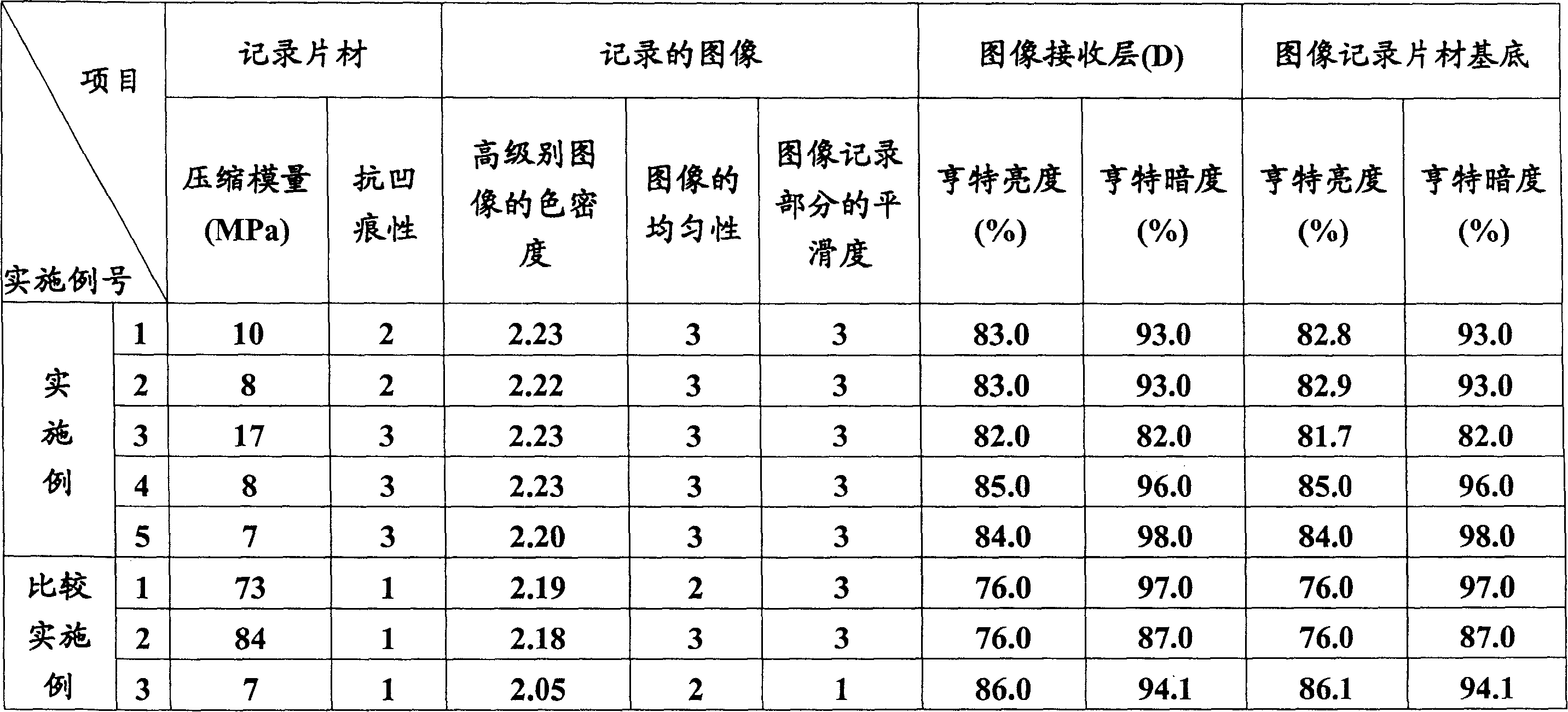

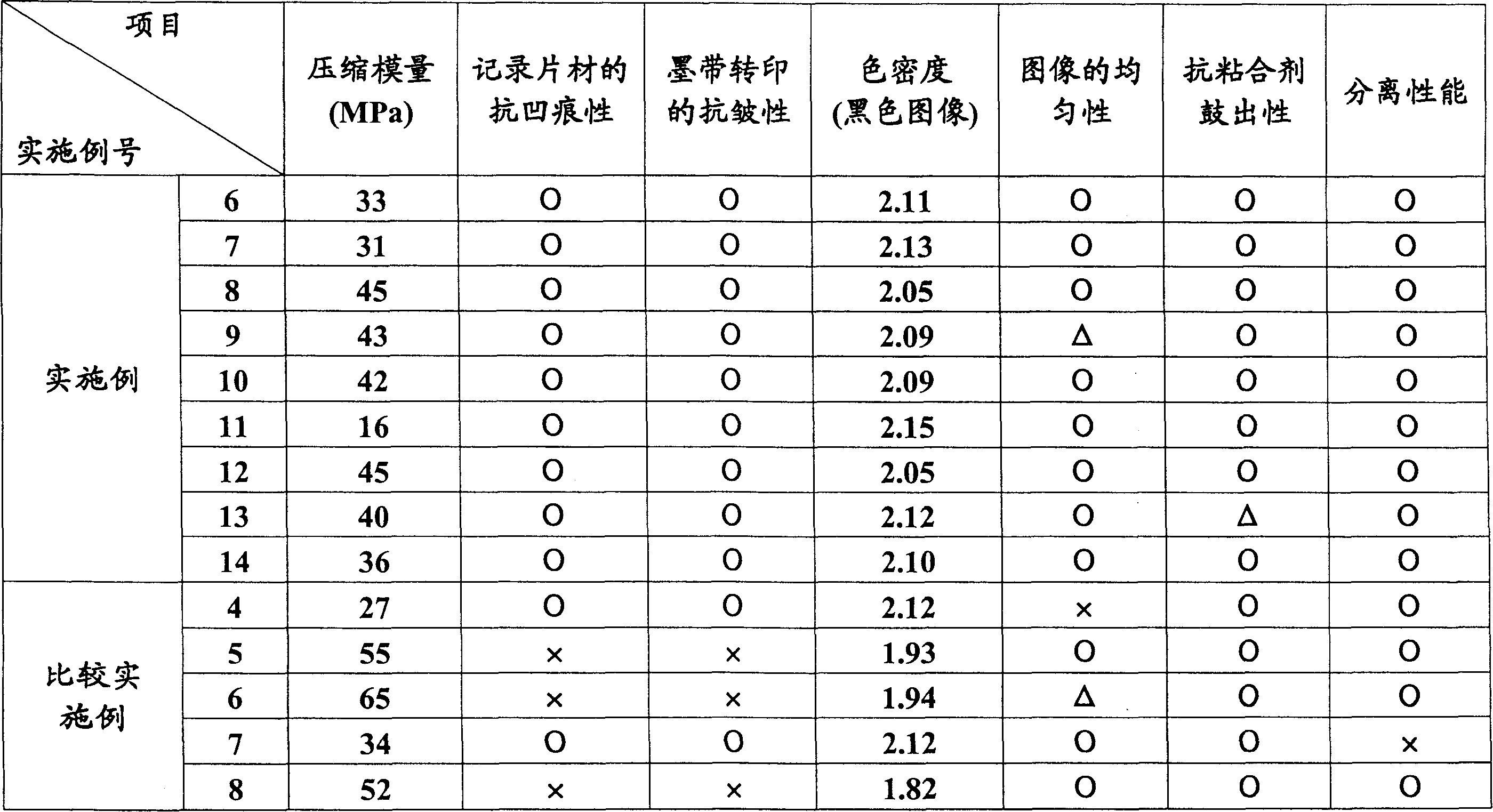

Embodiment 1

[0131] In the preparation of the image-recording sheet substrate (C) of the image-recording sheet, use a thickness of 50 micrometers and a reference mass of 50 g / m 2 , a compressive modulus of 50MPa oriented porous polyethylene terephthalate film (trade name: 50E63S, produced by TORAY) as the upper oriented porous polyester film layer (a), on which the upper oriented porous polyester film layer The front surface of (a) forms the image receiving layer (D); and using a thickness of 60 microns and a reference mass of 45 g / m 2, a porous synthetic paper sheet (trade name: YUPO FPG60 produced by YUPO Company) with a compressive modulus of 7 MPa as the lower oriented porous polymer film layer (b), after the lower oriented porous polymer film layer (b) The surface is coated with an adhesive layer (E).

[0132] Laminate the upper polyester film to the lower polymer film with a polyester adhesive by dry lamination to give a dry solids content of 4 g / m 2 image-recording sheet substrate...

Embodiment 2

[0171] A thermal transfer image-recording composite sheet was prepared in the same manner as in Example 1 except for the following differences.

[0172] With a thickness of 55 microns and a reference mass of 30g / m 2 And a porous polypropylene film (trade name: 260 LLG 302, produced by MOBILE) having a compression modulus of 5 MPa was used instead of the porous synthetic paper sheet (trade name: YUPO FPG60) for the lower oriented porous polymer film layer (b).

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com